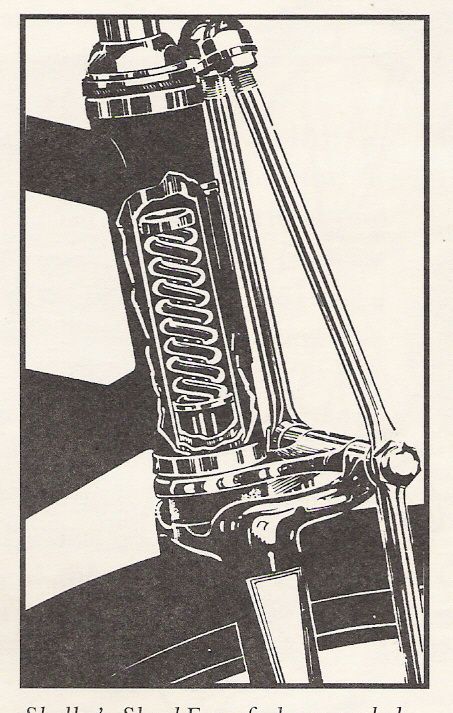

Hi guys, I've got an old shock-ease fork that I'm trying to put on a build of mine. Apparently the previous owner didn't like the way it worked because it's been brazed all around making it a rigid fork. I've been working on it for a few days trying to get it working properly again but I can't seem to find any close-up shots of how it works and I've been grinding away on the old bronze and still haven't gotten it loose. I just want to make sure I'm grinding away what I'm suppossed to. If any of you have experience with these forks and wouldn't mind explaining them to me I'd greatly appreciate it!

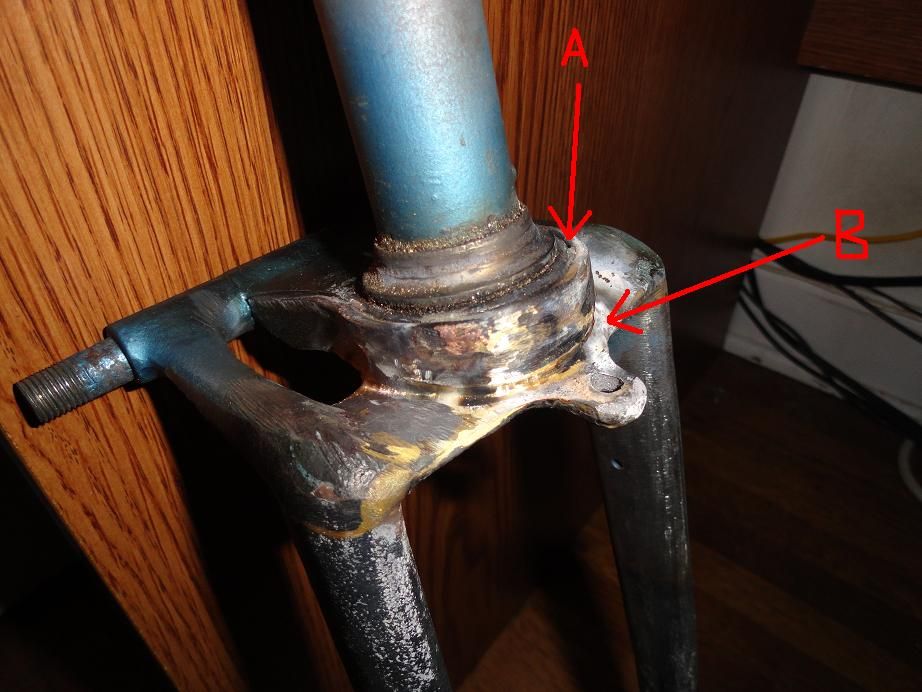

Here's the fork before I removed most of the braze:

Because of the way it was brazed I was under the impression that the forks came apart at point B but I've ground down all the way and I don't see where there's a separation so this leads me to believe that the forks come apart at point A. :? HELP PLEASE!!

I know the bottom pivots on the threaded bolt but the back splits somewhere when you hit a bump, is it point A or B or???

Also when I flip the forks upside down there was alot of braze on the bottom and I even found two spots where there's a weld(see red arrows). What needs to be ground away so the forks work?

I know that's alot but I'd really like to get these old forks working again. Thanks for any help and if you have close-up pics of your forks that would be a BIG help. Thanks!

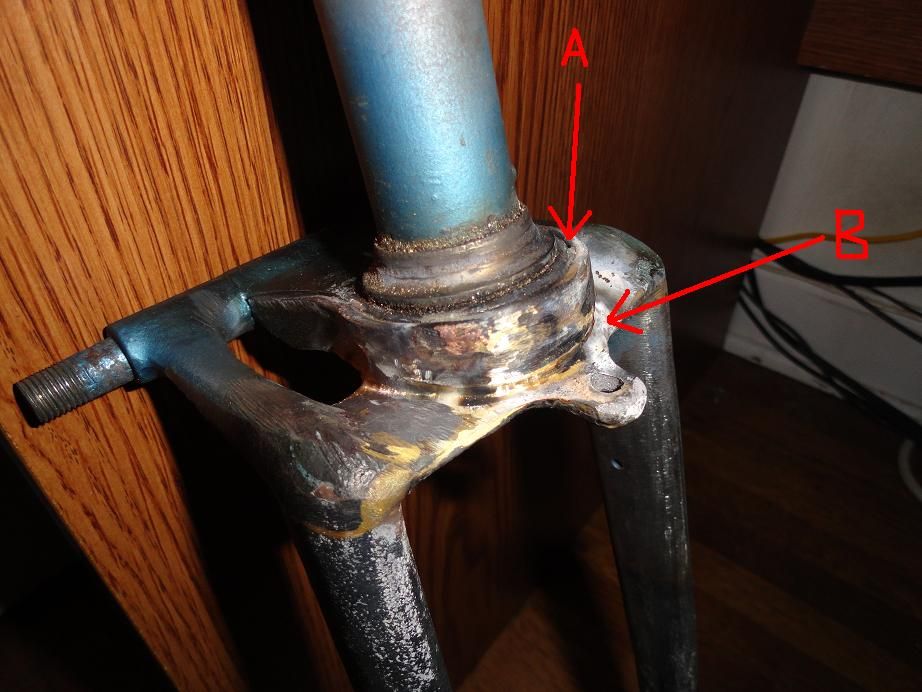

Here's the fork before I removed most of the braze:

Because of the way it was brazed I was under the impression that the forks came apart at point B but I've ground down all the way and I don't see where there's a separation so this leads me to believe that the forks come apart at point A. :? HELP PLEASE!!

I know the bottom pivots on the threaded bolt but the back splits somewhere when you hit a bump, is it point A or B or???

Also when I flip the forks upside down there was alot of braze on the bottom and I even found two spots where there's a weld(see red arrows). What needs to be ground away so the forks work?

I know that's alot but I'd really like to get these old forks working again. Thanks for any help and if you have close-up pics of your forks that would be a BIG help. Thanks!