I am not winning any Dad of the year awards this year. :?

This final build has spanned for months... all in waiting. The bike waiting for me to work on it! Numerous reasons have kept me from it, but now I'm re-engaged, and moving forward. So, my update in May said I had rebuilt the wheel and was spreading the frame. (rebuilding that wheel was a pain paying to get the spokes calculated) I got a better spreader from Harbor Freight (seen below) and it worked like a champ. However, the adapter I had for the rear brakes didn't fit right, and rear brakes would have taken a major modification. So, I asked for solutions, and an idea that a rear drum brake hub would work, and one was shown to me on E-bay, so I got it for under $30. I had to work closely with Robert at Wheels by Fleming and he walked me through how to measure for spoke length.

http://www.mrrabbit.net/wheelsbyfleming.php His custom spokes went on with a 2-cross lesson from him over the phone. So... now we move forward.

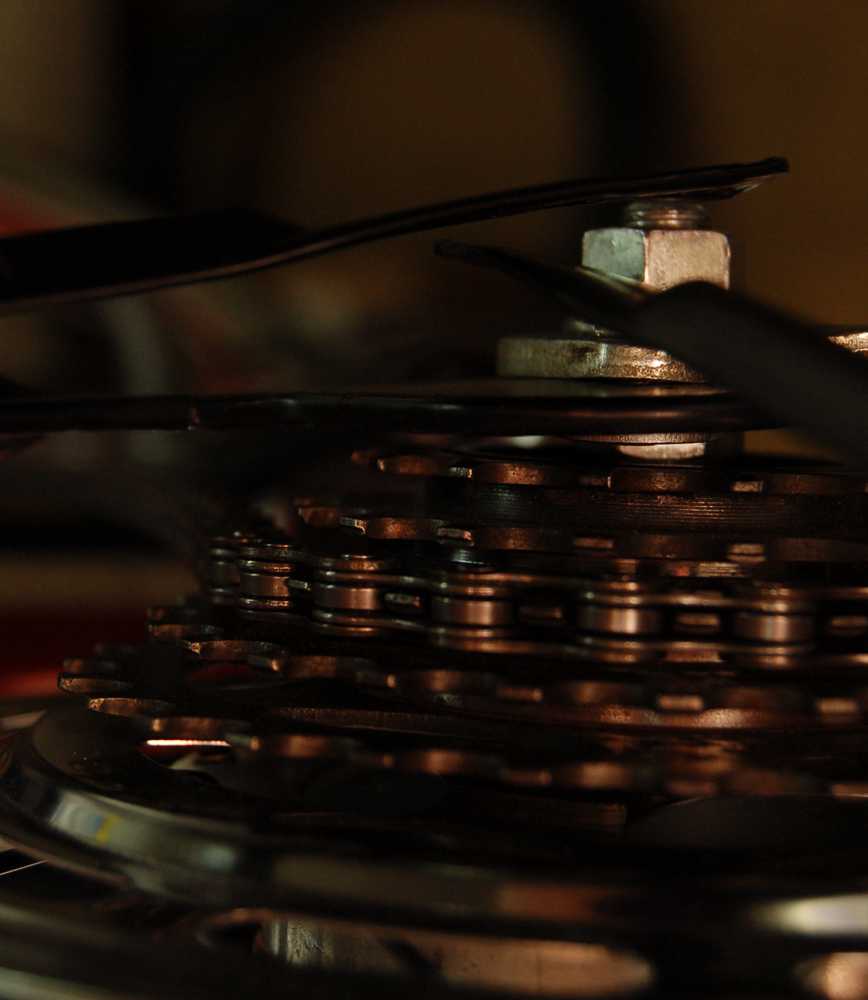

Here is the... built for the 3rd time... rear wheel. Notice the absense of the reflective tape stripe. The heat over the summer cracked the tape breaking the line! What the heck? So I'm replacing it. I think the front wheel is still all ok though. Very strange.

Here's the rear drop outs with a second drum brake hub I bought for a different build. The stays were having trouble keeping open to that width, so I decided to spread it, fit the hub in and tighten it down, then put even more pressure on the stays with that spreader while the hub keeps the drops where they need to be. I'm hoping after 3 days the stays will learn where they need to stay with the hub not in there.

This is the 26" Monark chain guard I orignally got for the build. It took a while for Adam to pin stripe it due to real life issues, but I finally got it for the second iteration of this build.

This is the cut I made tonight, then tried to smooth and touch up paint (still a little wet). I am no metal smith.

I still need to devise a way to attach it to that stay. But first I have to get the attachment to the down tube figured out, then I have to see if I'm going to cut and attach the fender brace to it. We'll see.

Steps forward:

- Getting the fender back on and situated with the new wheel's width.

- Getting the chain guard installed and looking like it's supposed to be there.

- Installing the shifter in a spot it will work and not kill my son trying to shift gears.

- Housing and cables.