I recently decided to build a tank for my “Strand Shark” project which is a 1938 Rollfast or Hawthorne Zep frame. The original tanks for these bikes fit completely inside the opening and did not cover the bars at all. I want this tank to partially cover the bars so it looks a little more streamlined.

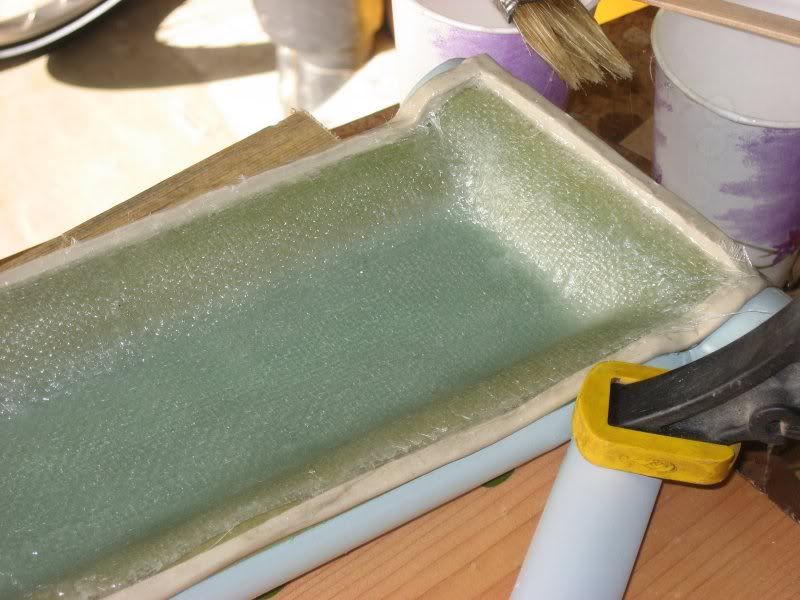

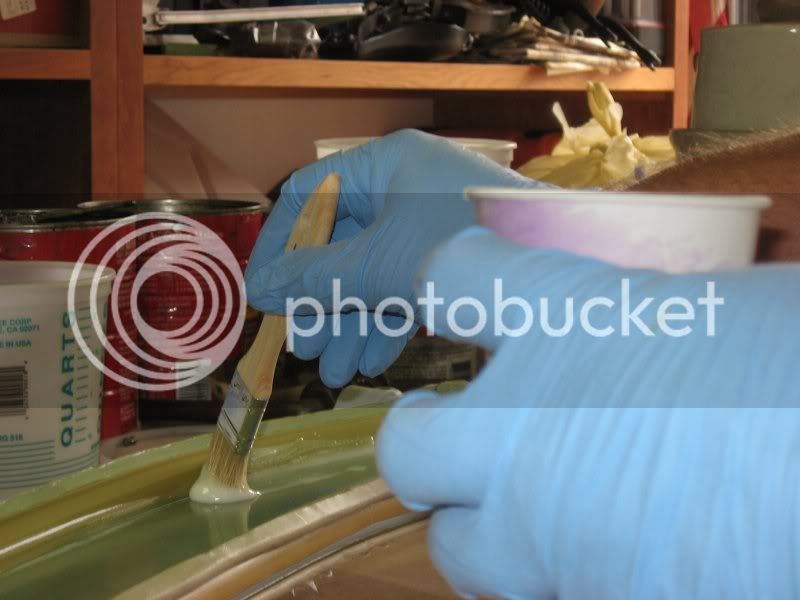

What I am working on now will become the inner plates for the tank halves. These two plates will meet in the middle and the tank halves will be built onto them.

Here I have clamped a piece of wood to the back side of the frame to give me a surface to work on. I have placed some blobs of modelers clay on the wood to support the parting board.

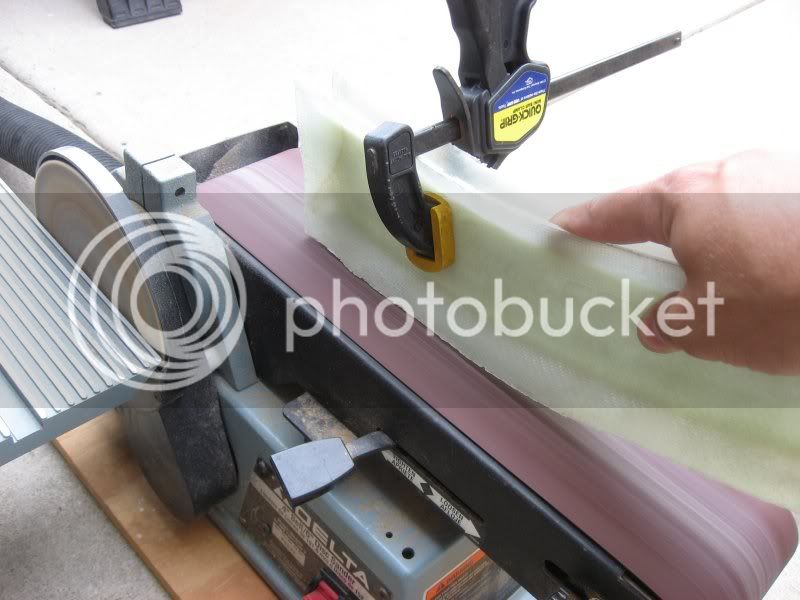

The parting board is just a piece of 1/4” hardboard cut to fit in the opening. I sprayed some scratch filler primer on one side and then sanded it smooth. Here I have squished it down onto the blobs of clay until the top surface is even with the marks I made on the centerline of the frame.

Next I filled in the gap with some modelers clay and then scraped off the excess with a razor blade.

What I am working on now will become the inner plates for the tank halves. These two plates will meet in the middle and the tank halves will be built onto them.

Here I have clamped a piece of wood to the back side of the frame to give me a surface to work on. I have placed some blobs of modelers clay on the wood to support the parting board.

The parting board is just a piece of 1/4” hardboard cut to fit in the opening. I sprayed some scratch filler primer on one side and then sanded it smooth. Here I have squished it down onto the blobs of clay until the top surface is even with the marks I made on the centerline of the frame.

Next I filled in the gap with some modelers clay and then scraped off the excess with a razor blade.