- Joined

- Oct 21, 2013

- Messages

- 211

- Reaction score

- 427

Very cool build. Love the fenders right on the tires.. and great flowing lines

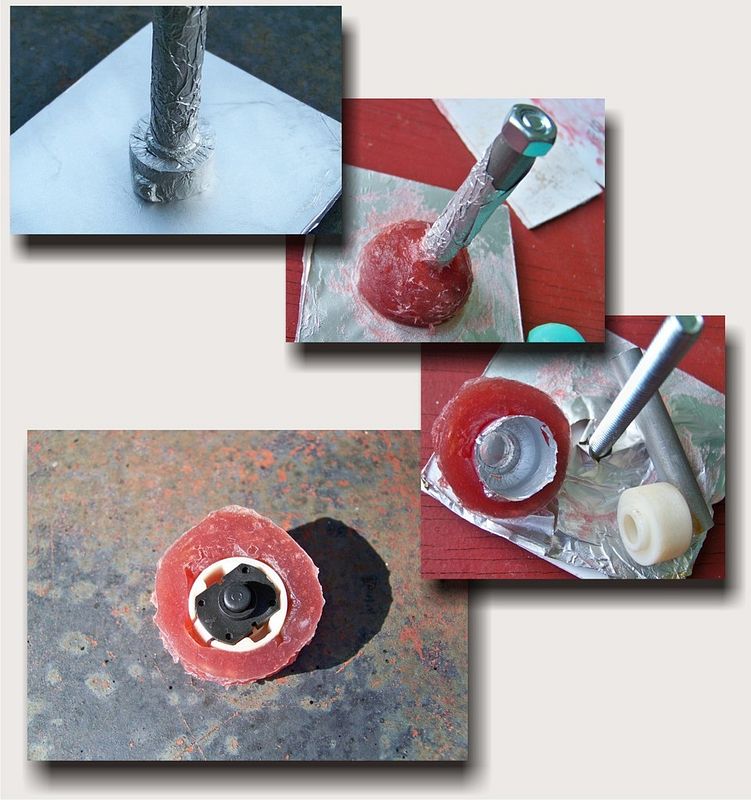

Thats awesome dude those were the days [emoji41]I remember when this article came out. I went down to the basement of oir house and used a hollowed out lamp post bolt and drilled and tapped the wedge nut in my stem.. I was the envy of all my friends and spent the next few weeks doing that to everyone elses bikes..i was 15-16 years old. I'm amazed that the cheap thin walled lamp post bolts never broke and someone getting hurt. We road like that on quarter pipe ramps and whatnot too. Pretty cool to see this article, I haven't thought about that in years

@c1run1 did a chrome tank last year. He partially painted it also. Scroll down to post #7 HERE.

It's interesting that you brought up carbon fiber, I had been considering that also! I'll leave that one for you since you brought it up first.Send me a conversation when you're ready and we'll talk about the holes.

Lots of simple solutions out there for that. I like to use the bolt on shimano ones for stops.

They're made to bolt to a brazed on shifter boss but I just drill + tap + use a longer screw. Lots of tastefull clamp on guides to just hold the cables.

ahh i was looking for something like this where can i find them

Enter your email address to join: