Here i go again ,

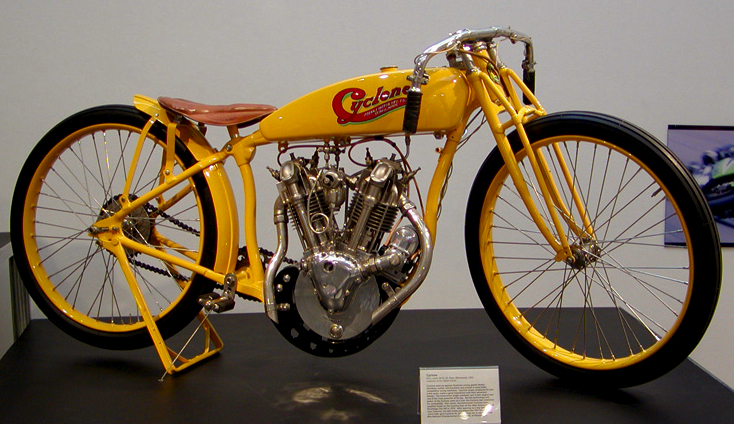

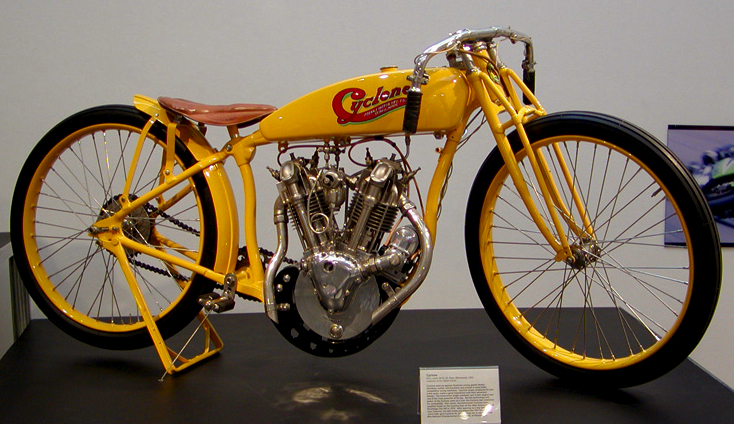

this time iam set on building a replica of my dream bike : 1914 Cyclone BoardTrackRacer

i plan to motorize it ''Electric'',with curiously a motor named Cyclone, but ill want to build it as close to the original as possible while still being practicle .

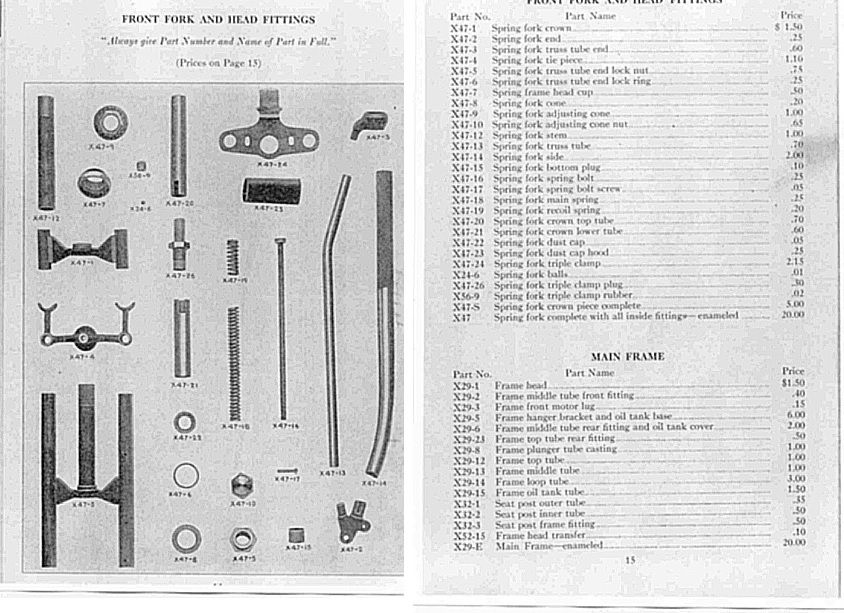

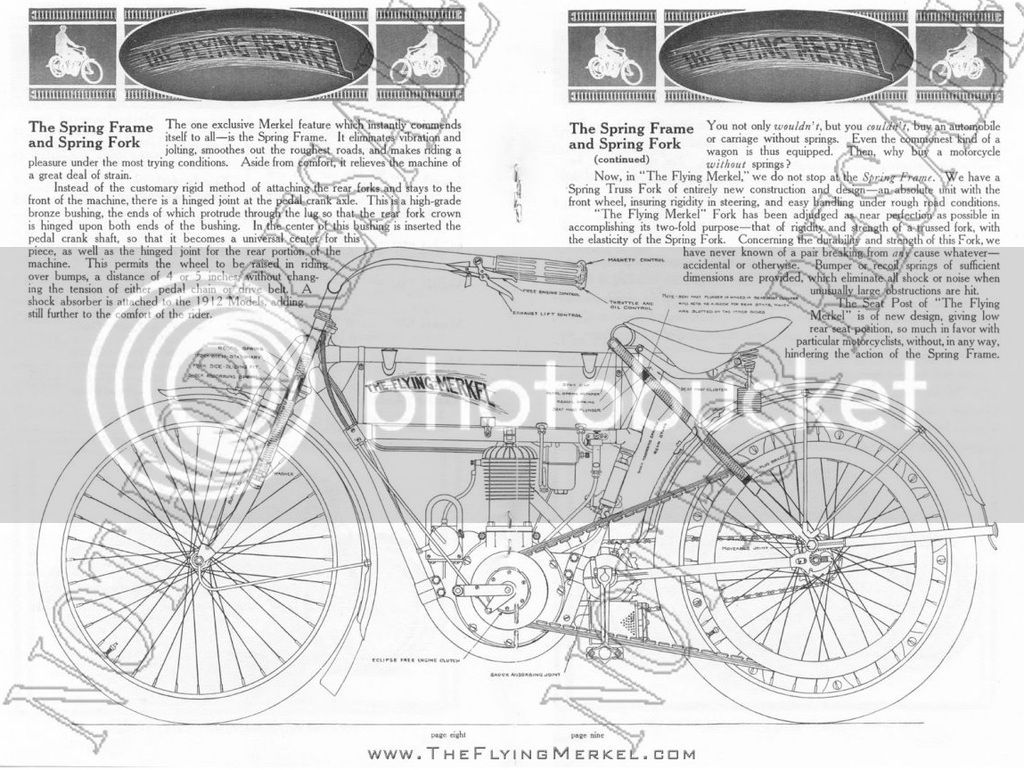

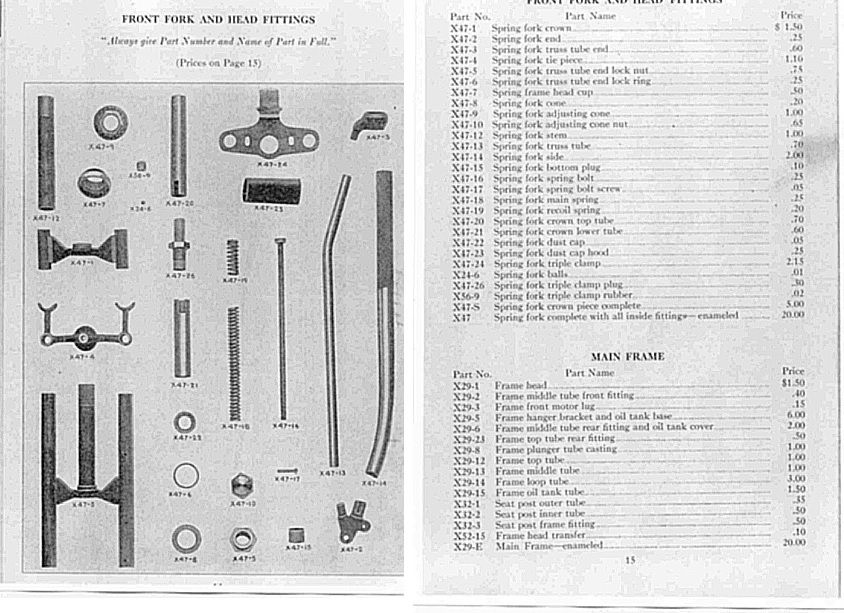

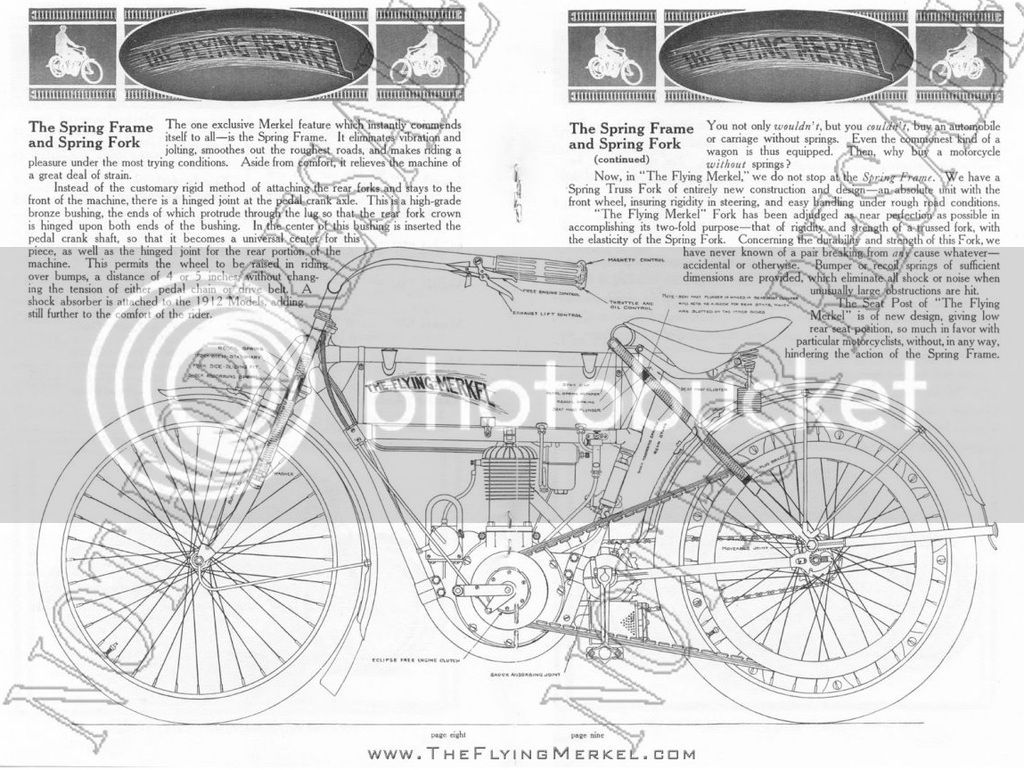

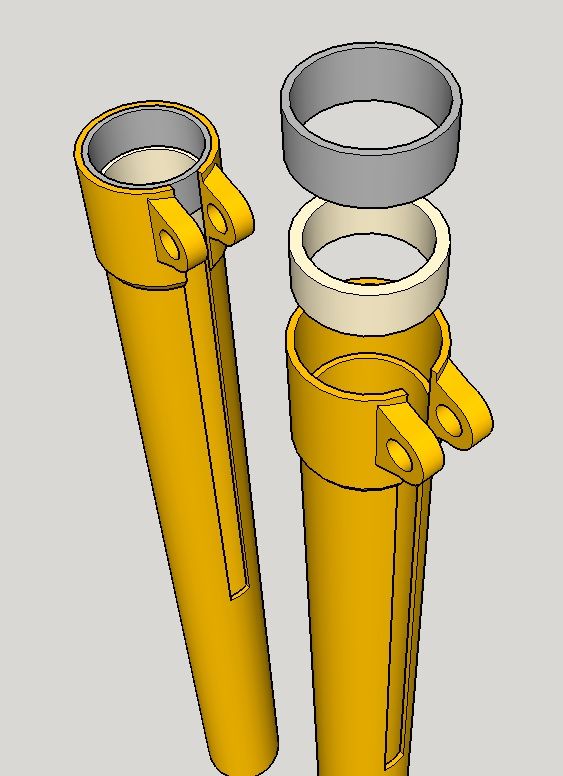

i already started with the fork , wich is a 'Flying Merkel fork , the pioneer of the modern tellescopic suspension forks.

the original fork had no friction sleeves and a weird 3 part inner tube

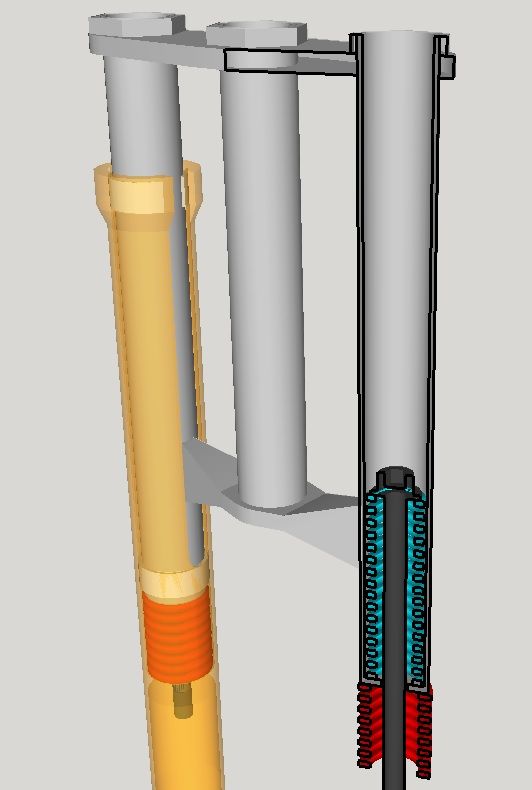

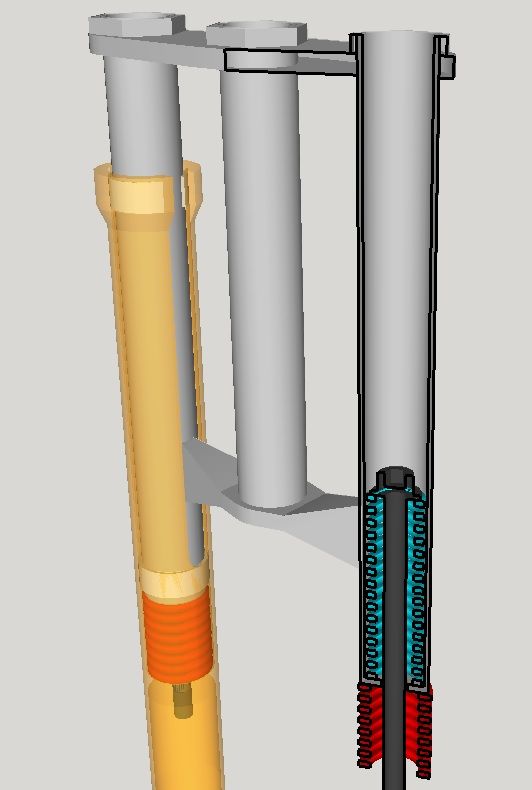

so i decided to make it my own way ,more simple, more like a modern fork , with the return spring inside the inner tube , and the compression spring under the tubes

made the inner tubes using plumbing pipes polished on the wood lathe, plumbing fitting as risers/top nut,

and nylon hose fittings for the friction sleeves .

-Using seat clamps as bar clamps , i welded a 3/8'' nut inside the top of the plumbing fittings...

-Capped a steerer tube topnut...

-Made the top plate by grinding 2 halfs with half holes and then welded togeter(cause iam not equipped to drill that big)

-Used one peice crank locknuts welded on the tubes to make a shoulder for the top plate...

Made a groove for the nylon sleeves to lock on , used a hss boring bar and files on my wood lathe(i do with what i have)

Ouuhh Yeah! ive made new shorter riser wich look much cleaner , and top plate is done!

ive made new shorter riser wich look much cleaner , and top plate is done!

not sure yet if i put the top sleeves fixed on the inner tubes or the outer tubes .

ill go get some tubing to extend the outer fork legs soon , at thats moment ill know what diameter to lathe the sleeves.

have to lathe everything and test the sliding action before i can weld the bottom support that joins the legs with the steerer tube and notch the outer legs

this time iam set on building a replica of my dream bike : 1914 Cyclone BoardTrackRacer

i plan to motorize it ''Electric'',with curiously a motor named Cyclone, but ill want to build it as close to the original as possible while still being practicle .

i already started with the fork , wich is a 'Flying Merkel fork , the pioneer of the modern tellescopic suspension forks.

the original fork had no friction sleeves and a weird 3 part inner tube

so i decided to make it my own way ,more simple, more like a modern fork , with the return spring inside the inner tube , and the compression spring under the tubes

made the inner tubes using plumbing pipes polished on the wood lathe, plumbing fitting as risers/top nut,

and nylon hose fittings for the friction sleeves .

-Using seat clamps as bar clamps , i welded a 3/8'' nut inside the top of the plumbing fittings...

-Capped a steerer tube topnut...

-Made the top plate by grinding 2 halfs with half holes and then welded togeter(cause iam not equipped to drill that big)

-Used one peice crank locknuts welded on the tubes to make a shoulder for the top plate...

Made a groove for the nylon sleeves to lock on , used a hss boring bar and files on my wood lathe(i do with what i have)

Ouuhh Yeah!

ive made new shorter riser wich look much cleaner , and top plate is done!

ive made new shorter riser wich look much cleaner , and top plate is done!

not sure yet if i put the top sleeves fixed on the inner tubes or the outer tubes .

ill go get some tubing to extend the outer fork legs soon , at thats moment ill know what diameter to lathe the sleeves.

have to lathe everything and test the sliding action before i can weld the bottom support that joins the legs with the steerer tube and notch the outer legs

Last edited:

more simple and faster!

more simple and faster!

so well worth it imo

so well worth it imo