You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

UCB Hub Project- Perry Two Star B-100 Rebuild

- Thread starter udallcustombikes

- Start date

Help Support Rat Rod Bikes Bicycle Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

cjperry81

Gem City Strongman

Re: Perry Two Star B-100 Rebuild

My answer would be yes I guess lol this is as far as I've gotten. I didn't take the snap ring that I know of. I looked at the factory break down sheet you posted but I can't figure out what the snap ring actually is.udallcustombikes said:Are you having trouble getting the driver apart? Have you removed the snap ring?

Re: Perry Two Star B-100 Rebuild

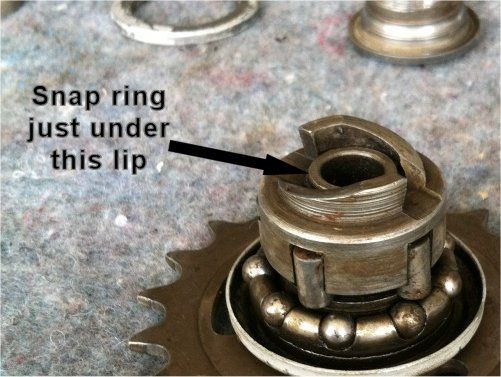

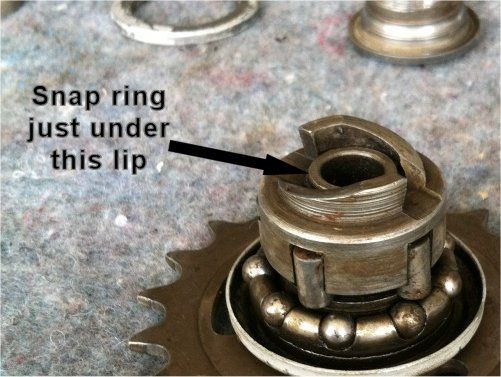

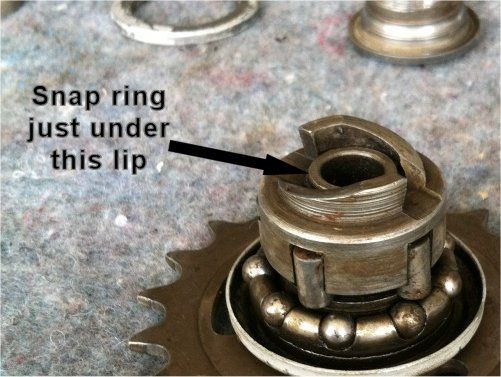

There is a small snap ring (like the ones that holds the sprocket on a newer style coaster hubs) on the top of the roller guide. If you can't find it I will take some good pics of my cut away to show you where it is when I get home.

There is a small snap ring (like the ones that holds the sprocket on a newer style coaster hubs) on the top of the roller guide. If you can't find it I will take some good pics of my cut away to show you where it is when I get home.

cjperry81

Gem City Strongman

Re: Perry Two Star B-100 Rebuild

Sorry to be annoying but im just not seeing it. The pics I have there are what im looking at so I dont know where the snap ring is supposed to be.

udallcustombikes said:There is a small snap ring (like the ones that holds the sprocket on a newer style coaster hubs) on the top of the roller guide. If you can't find it I will take some good pics of my cut away to show you where it is when I get home.

Sorry to be annoying but im just not seeing it. The pics I have there are what im looking at so I dont know where the snap ring is supposed to be.

Re: Perry Two Star B-100 Rebuild

try this...

try this...

cjperry81

Gem City Strongman

Re: Perry Two Star B-100 Rebuild

Thanks so much for the help. I couldnt see that snap ring for the life of me. Well I got it off and now here of pics of where I am. Is there further disassembly and also how do I reach these 2 sets of bearings. They are gunked up for sure even after a substantial gasoline soak and I cant get anything to budge to get them out. Advice?

Ratfink1962 said:try this...

Thanks so much for the help. I couldnt see that snap ring for the life of me. Well I got it off and now here of pics of where I am. Is there further disassembly and also how do I reach these 2 sets of bearings. They are gunked up for sure even after a substantial gasoline soak and I cant get anything to budge to get them out. Advice?

cjperry81

Gem City Strongman

Re: Perry Two Star B-100 Rebuild

So I did everything I could to get those dust covers off without damaaging them but they would budge. So i left them on and just blew some air in the bearing rings, scrubbed them out, and then greased them. So i put the whole thing back together but it just doesnt seem right. Everything thing fit great and went together smooth but now that its done it just doesnt seem like its rotating smoothly. Just seems like alot of friction inside. But I dont actually know what its supposed to be like. Should I take a video of it and post it on here or youtube so you can see it? I dont wanna lace this wheel up and have the hub be all wrong.

udallcustombikes said:To get those bearings out you need to gently pry the dust covers off. They will be in there good and tight so take your time and be careful.

So I did everything I could to get those dust covers off without damaaging them but they would budge. So i left them on and just blew some air in the bearing rings, scrubbed them out, and then greased them. So i put the whole thing back together but it just doesnt seem right. Everything thing fit great and went together smooth but now that its done it just doesnt seem like its rotating smoothly. Just seems like alot of friction inside. But I dont actually know what its supposed to be like. Should I take a video of it and post it on here or youtube so you can see it? I dont wanna lace this wheel up and have the hub be all wrong.

Cameron or anyone else that knows-

WIth other coaster hubs (New Departure for example) I've been told to just grease the actual bearings and then drop some '3 in 1' oil into the oiler cap.

I assume that is the case with the Perry also?

Thanks.

Bruce

WIth other coaster hubs (New Departure for example) I've been told to just grease the actual bearings and then drop some '3 in 1' oil into the oiler cap.

I assume that is the case with the Perry also?

Thanks.

Bruce

Miscellaneous ramblings...

The Perry is a licensed copy of the F&S Torpedo, German, dating way way back. The same design is still sold new today as the "Velosteel". I have collected various other copies of the Torpedo made in other European countries but they are all of lower quality than the Perry.

I have collected various other copies of the Torpedo made in other European countries but they are all of lower quality than the Perry.

Unlike most other hubs, which are meant to come apart from the driver side, these are meant to come apart from the brake side. The first challenge is nobody has a proper tool to loosen that "notched ring" they use for a locknut. I use channel lock pliers but they do scar the part.

The adjusting cone is meant to remain stationary on the axle, but about half the time they will come coose if you can't get the brake side loose. There are no flats on it to accomodate a wrench.

I do NOT dissassemble the driver. I do NOT attempt to remove the dustcovers that retain the bearings on the brake side of the hub or cog side of the driver. It is too hard and too risky for most casual mechanics, and not really necessary. I soak and scrub the assemblies for a good long time untill I am satisfied that all the resultant access-impaired cavities are cleaned out. I then visually inspect the bearings and visible races for damage.

If something is going to be damaged, it will usually be the adjusting cone and accompanying bearings. Most times it is rust and not wear.

I squish grease into all those access-impaired cavities with my fingers and reassemble.

The adjustment process is quirky and hard for even me to warm up to. Instead of adjusting the adjusting cone and then locking it down (as with all others)... you leave the lock nut on the LEFT side loose, turn the adjusting cone BY TURNING THE AXLE using its square end, then lock down the left side.

The axle uses standard threads, so you could replace the lock nut (ring) with a hex head if desired. I have not stooped that low as of yet.

I have seen 2 types of brake shoes. The single piece brass cylinder (earlier) has worked less well for me. The 2 piece segmented black assembly has worked better for me.

Some people claim the Velosteels work better with oil instead of grease... but I have never had any problem with grease in my Perrys.

The Perry is a licensed copy of the F&S Torpedo, German, dating way way back. The same design is still sold new today as the "Velosteel".

Unlike most other hubs, which are meant to come apart from the driver side, these are meant to come apart from the brake side. The first challenge is nobody has a proper tool to loosen that "notched ring" they use for a locknut. I use channel lock pliers but they do scar the part.

The adjusting cone is meant to remain stationary on the axle, but about half the time they will come coose if you can't get the brake side loose. There are no flats on it to accomodate a wrench.

I do NOT dissassemble the driver. I do NOT attempt to remove the dustcovers that retain the bearings on the brake side of the hub or cog side of the driver. It is too hard and too risky for most casual mechanics, and not really necessary. I soak and scrub the assemblies for a good long time untill I am satisfied that all the resultant access-impaired cavities are cleaned out. I then visually inspect the bearings and visible races for damage.

If something is going to be damaged, it will usually be the adjusting cone and accompanying bearings. Most times it is rust and not wear.

I squish grease into all those access-impaired cavities with my fingers and reassemble.

The adjustment process is quirky and hard for even me to warm up to. Instead of adjusting the adjusting cone and then locking it down (as with all others)... you leave the lock nut on the LEFT side loose, turn the adjusting cone BY TURNING THE AXLE using its square end, then lock down the left side.

The axle uses standard threads, so you could replace the lock nut (ring) with a hex head if desired. I have not stooped that low as of yet.

I have seen 2 types of brake shoes. The single piece brass cylinder (earlier) has worked less well for me. The 2 piece segmented black assembly has worked better for me.

Some people claim the Velosteels work better with oil instead of grease... but I have never had any problem with grease in my Perrys.

Last edited:

I cleaned and greased a Perry hub today. Checked out this how to first. I did the quick and dirty where I left dust shields in place. My hub had a 59 date on the brake arm and used the brass cylinder type brake shoe. I de-glazed the inside of the hub while apart. After reassembly, I noticed that the hub was inconsistent on engagement following braking. I adjusted and readjusted, no change. I had opened a new can of grease for this hub, and it seemed quite a bit stiffer than the grease I had previously been using. I disassembled the hub and wiped out a lot of grease that was not on a bearing or a brake. Reassembled and working much better now. Was the grease the problem? At any rate, that problem is fixed, but the braking is marginal at best.

FWIW, and i see that others have had other experiences, you'll want to use # 00 grease or heavy oil on a coaster hub that has either disc-style shoes or ones that have roller bearings in the clutch. When i first started to mess around with Velosteels, I was treatin'm like you would a Bendix or a Shimano-- lots of heavy/tacky grease. The hubs suffered from terrible engagement and very weak braking. Nowadays, I treat Velosteels and Torpedoes like folks typically suggest for ND hubs... Grease the ball bearings in the races, but everything in the center (brakes, clutch cone, rollers) gets some SAE 30 oil.... but i'm planning to play around with higher viscosity single-grade oils in the future.

I got a Perry hub too, now, but i haven't laced it yet... but all of these hubs use the same design in terms of roller bearings in the clutch and breakdown for service coming from the DS instead of the NDS. If you weigh down those rollers with heavy grease, you'll have trouble both engaging and braking....

I got a Perry hub too, now, but i haven't laced it yet... but all of these hubs use the same design in terms of roller bearings in the clutch and breakdown for service coming from the DS instead of the NDS. If you weigh down those rollers with heavy grease, you'll have trouble both engaging and braking....

I know a guy who is vision impaired. He can't drive but he can ride a bike. His bike was stolen, and it was costing him a lot to ride the bus. I showed him seven bikes and of course he picked the one with the Perry hub. I couldn't let it go without trying to get the brakes working better. Next time I'll treat it like a ND.

When I rebuilt my New Departure hub I used Lucas oil additive on the discs - very thick stuff. Kind of acted like a fixie no coaster for a few miles, just before I got home and pulled it apart it unstuck. Since then it's been fine.

When I rebuilt my New Departure hub I used Lucas oil additive on the discs - very thick stuff. Kind of acted like a fixie no coaster for a few miles, just before I got home and pulled it apart it unstuck. Since then it's been fine.

Interesting....