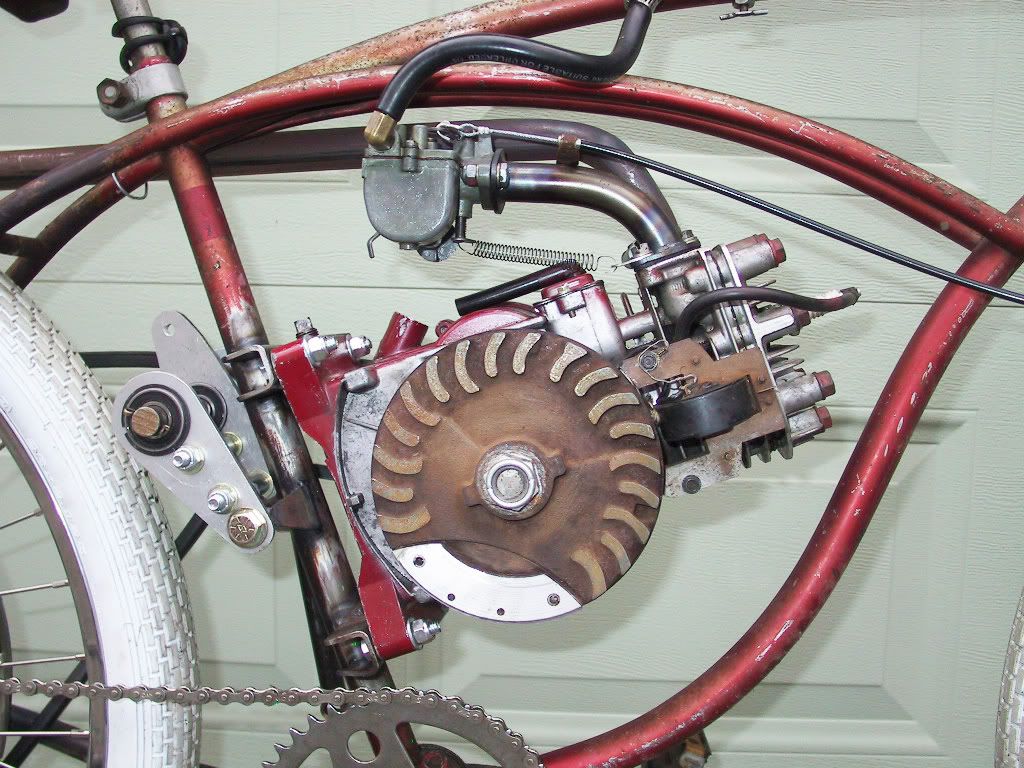

I’ve had a new idea for a motor bicycle. I wanted to take a small (2.5-3.5hp) Briggs and Stratton engine and mount it inclined. The bottom of the motor would mount on the seat tube.

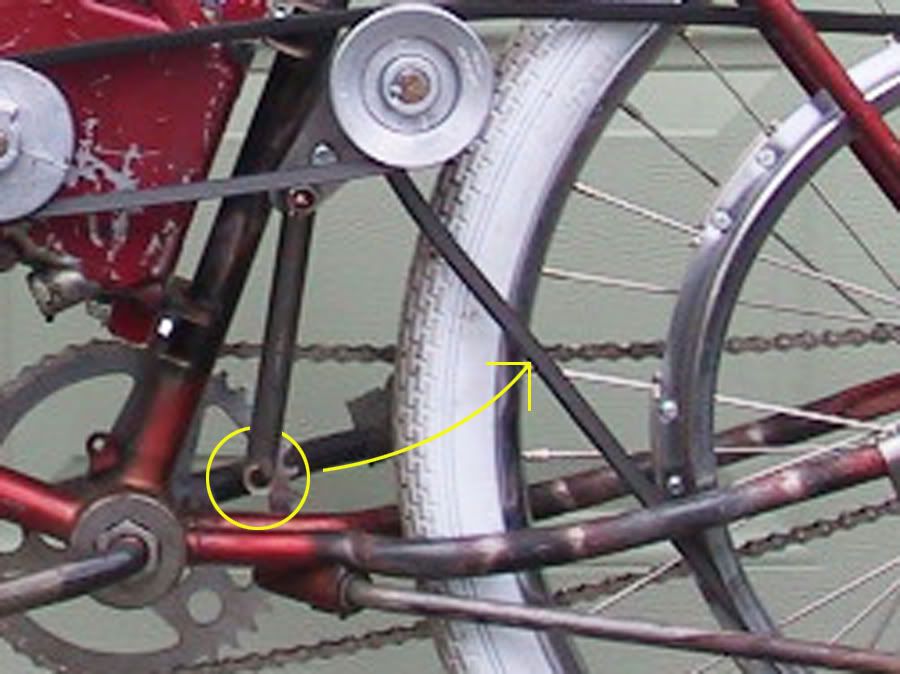

I planned to have a belt drive with a belt-tensioning clutch. The engine would run to a jackshaft just behind the seat tube, then on to a sheave on the back wheel.

In order for it NOT to look like a normal Briggs, I planned to take off the air shrouding, trim down the fan blades on the flywheel, shorten the crankshaft at both ends, remove any excess aluminum air directional shrouds on the cylinder and reshape the cylinder as round as I can get it.

The intake and exhaust would be on top of the motor. Also, the little oil slinger will dip down into the new, tilted over bottom end and fling the oil just right. I figured I’d have to drill and tap a new drain plug and filler plug and figure out some sort of dip stick to check the oil level.

I’ll use a small Tillotson carb on a new intake manifold. I wasn’t quite sure what I wanted to do for the exhaust.

Since I am using a Schwinn cruiser frame, there’s more than enough room.

So that was the plan.

- boogerballs

I planned to have a belt drive with a belt-tensioning clutch. The engine would run to a jackshaft just behind the seat tube, then on to a sheave on the back wheel.

In order for it NOT to look like a normal Briggs, I planned to take off the air shrouding, trim down the fan blades on the flywheel, shorten the crankshaft at both ends, remove any excess aluminum air directional shrouds on the cylinder and reshape the cylinder as round as I can get it.

The intake and exhaust would be on top of the motor. Also, the little oil slinger will dip down into the new, tilted over bottom end and fling the oil just right. I figured I’d have to drill and tap a new drain plug and filler plug and figure out some sort of dip stick to check the oil level.

I’ll use a small Tillotson carb on a new intake manifold. I wasn’t quite sure what I wanted to do for the exhaust.

Since I am using a Schwinn cruiser frame, there’s more than enough room.

So that was the plan.

- boogerballs