Picked up this old Schwinn Motobike frame at a swap meet. It’s had a rough life as evidenced by the bumps and bruises under the blue paint.

It came with a fork sans the truss rods. I had some other parts for it so I began some mock-up work for the $10 frame.

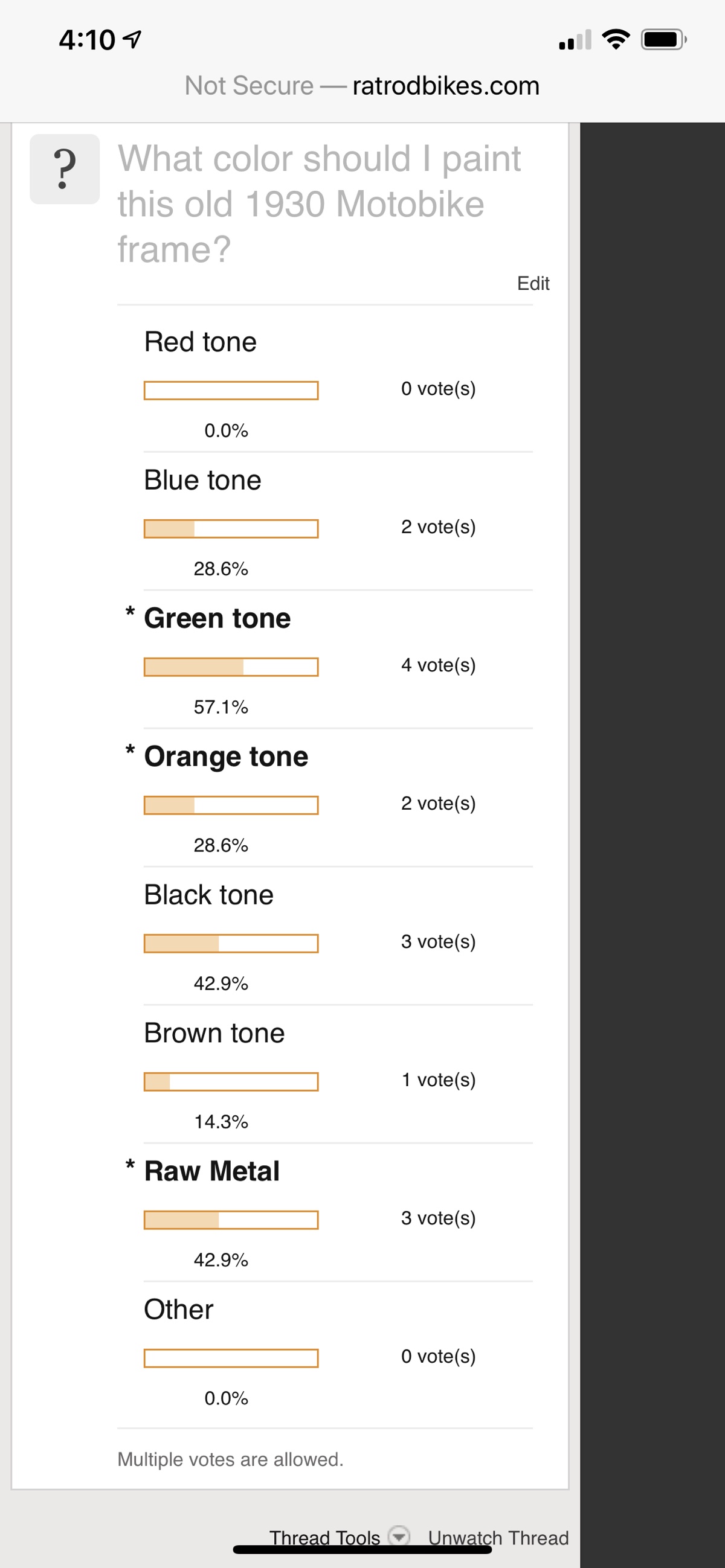

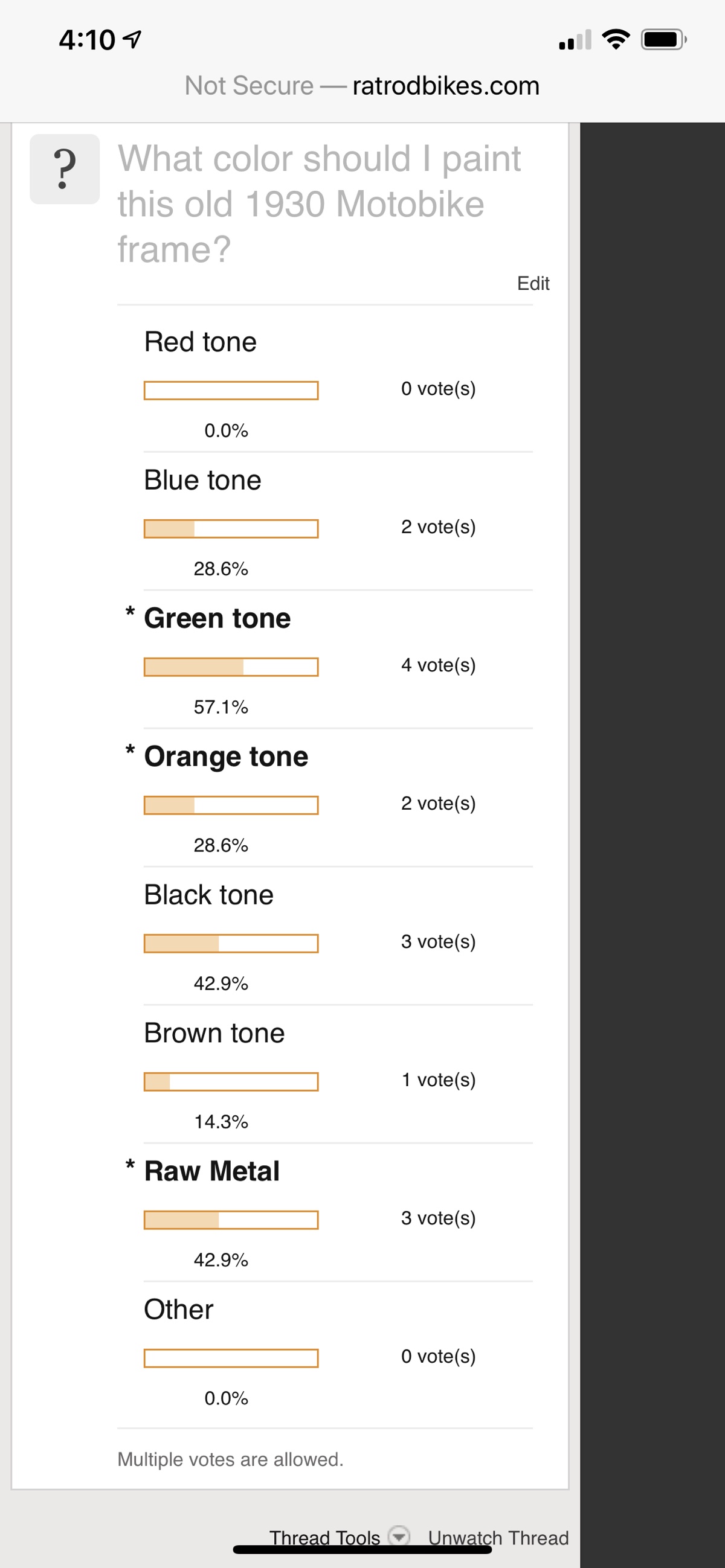

I ran a survey for determination of a base color. The results so far are either for green or black.

Sent from my iPhone using Tapatalk

It came with a fork sans the truss rods. I had some other parts for it so I began some mock-up work for the $10 frame.

I ran a survey for determination of a base color. The results so far are either for green or black.

Sent from my iPhone using Tapatalk

Last edited: