Do you need help with the math to the back wheel, or how to set up the jackshaft.

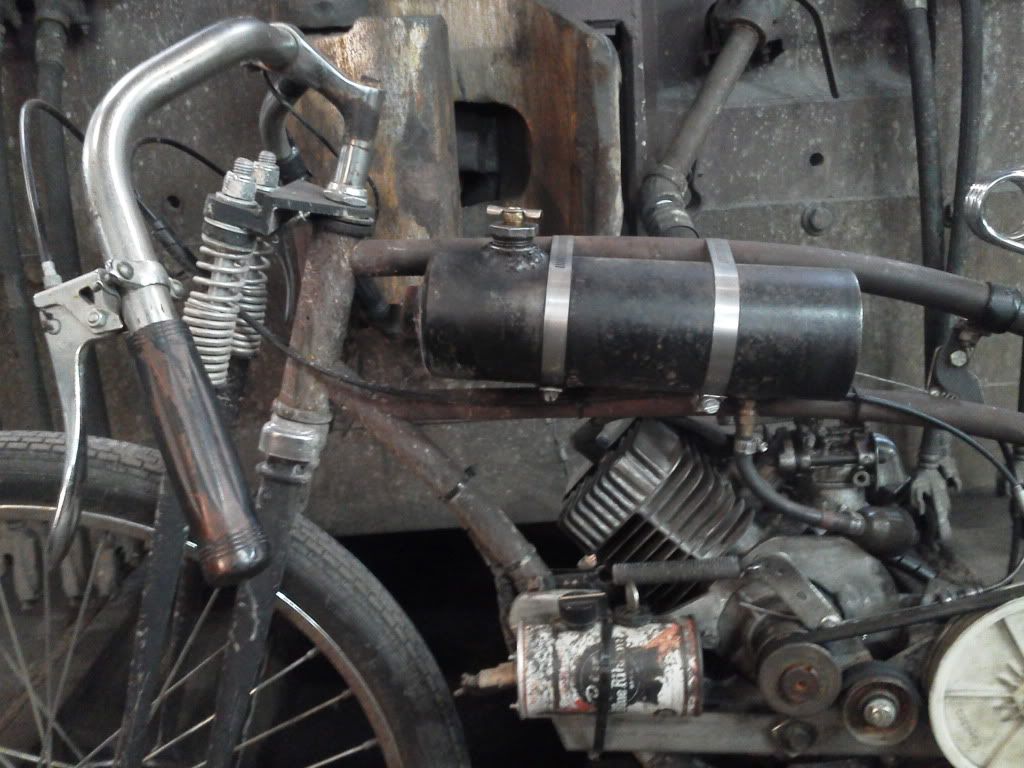

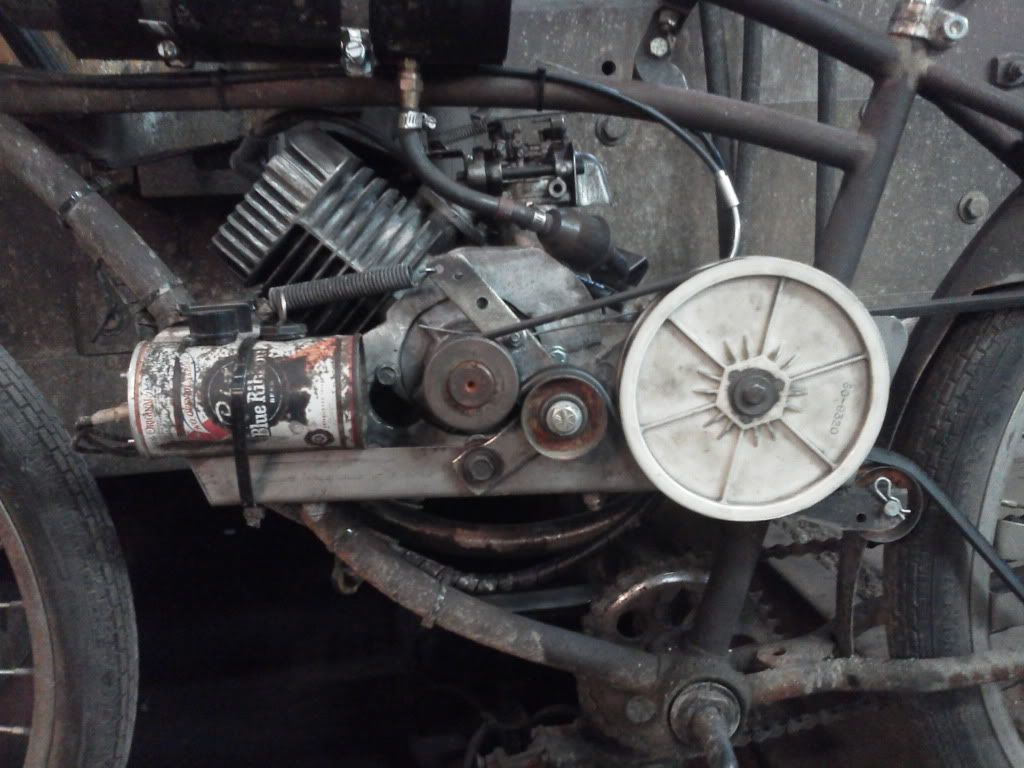

I went with chain the first try but had the math all wrong so i switched to belts, the hoop from a 20'' rim makes a fine pulley.

I went with chain the first try but had the math all wrong so i switched to belts, the hoop from a 20'' rim makes a fine pulley.