I've decided to try a new design on an old method. I'm calling it the buddha because of it's fat, belly like shape.

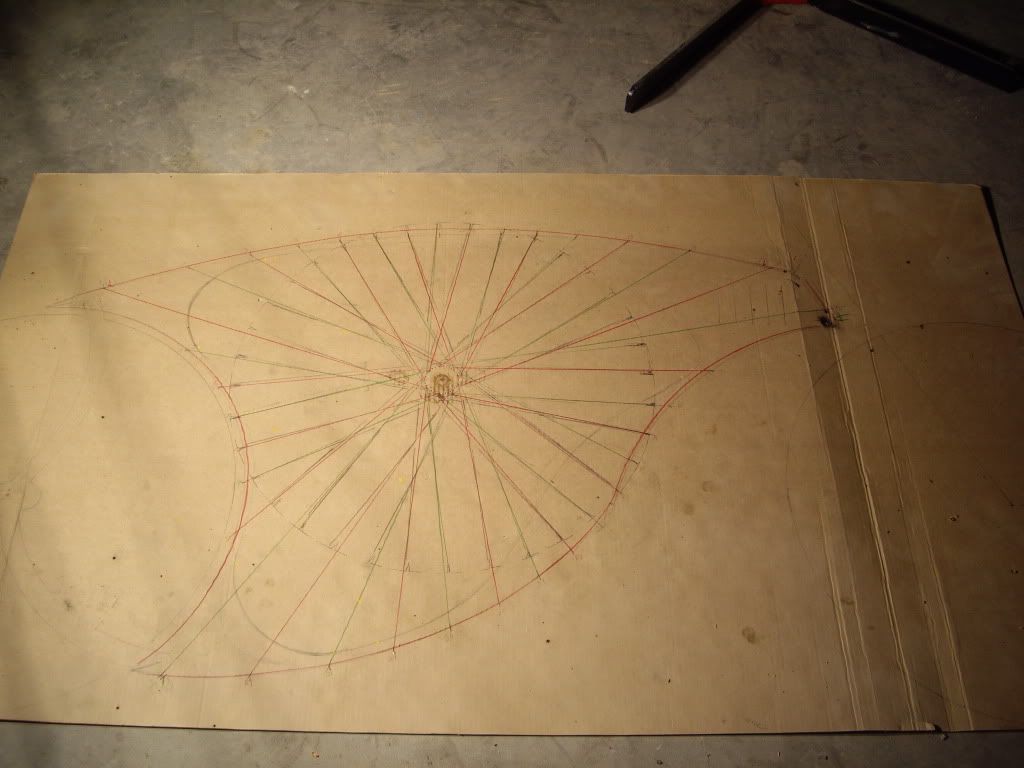

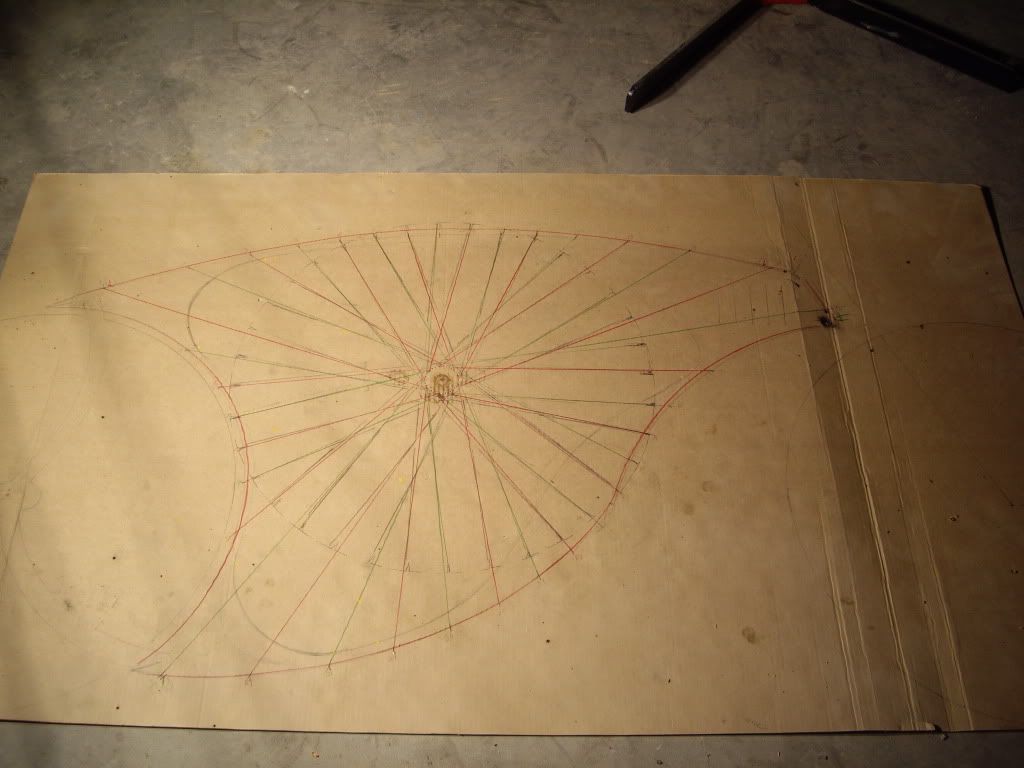

This is the basic design using my proprietary CAD ( cardboard aided drawing) software.

These are the rolled and formed 20 gauge sheetmetal pieces welded together.

I'll hopefully have more to post tomorrow. This bike will be more rat rod looking than my others. I've got some whitewall Thick Bricks and a few other ideas.

This is the basic design using my proprietary CAD ( cardboard aided drawing) software.

These are the rolled and formed 20 gauge sheetmetal pieces welded together.

I'll hopefully have more to post tomorrow. This bike will be more rat rod looking than my others. I've got some whitewall Thick Bricks and a few other ideas.