I recently restored a Murray Jet-Fire (see build thread; viewtopic.php?f=21&t=35534 ), before I got started I knew that I would be repainting the bike and would need replacement decals.

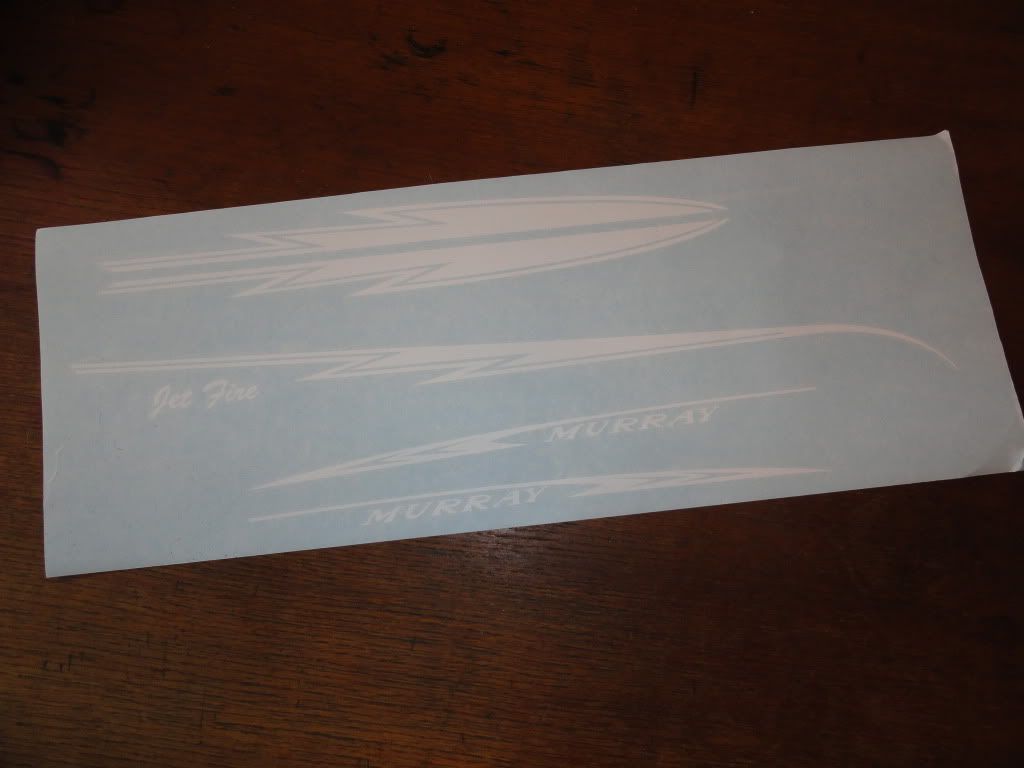

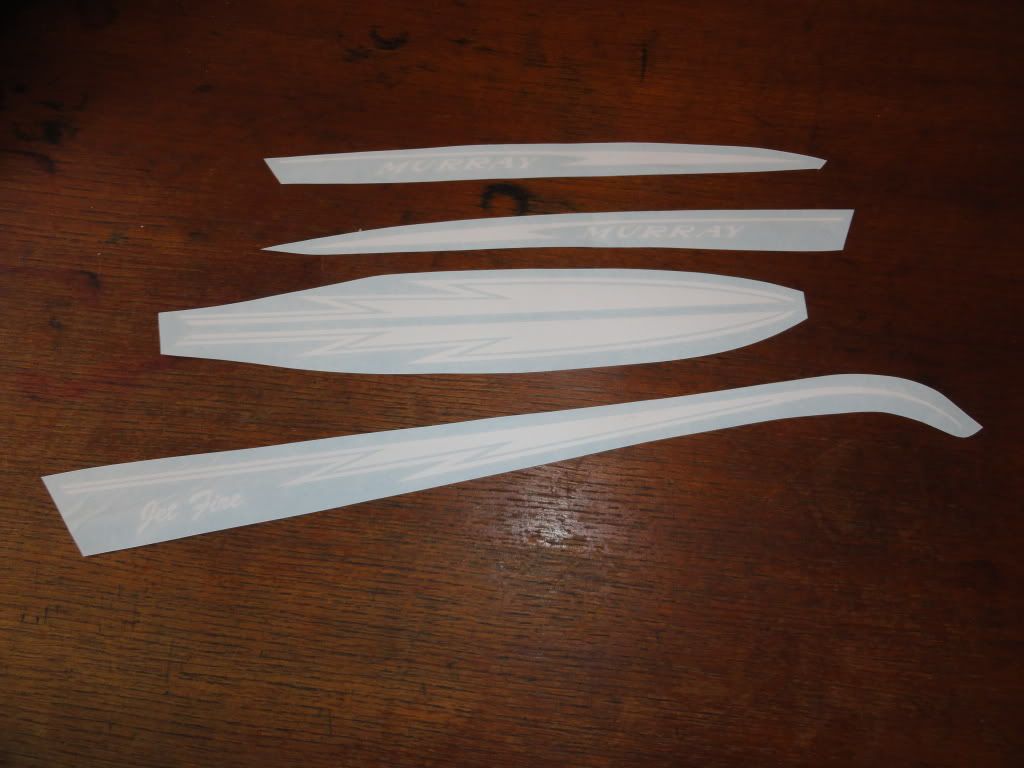

I looked high and low and no one makes or reproduces decals for this particular bike, so I decided to have some custom made at a local sign shop (Houston Sign Company).

Here is the subject bike in it's 'before' condition.

I dropped the tank, rack and chainguard off at the sign shop to let them do their thing, which only took a couple of days.

It's a good idea to take several pictures before hand so you'll know how the decals are positioned on each part.

I looked high and low and no one makes or reproduces decals for this particular bike, so I decided to have some custom made at a local sign shop (Houston Sign Company).

Here is the subject bike in it's 'before' condition.

I dropped the tank, rack and chainguard off at the sign shop to let them do their thing, which only took a couple of days.

It's a good idea to take several pictures before hand so you'll know how the decals are positioned on each part.