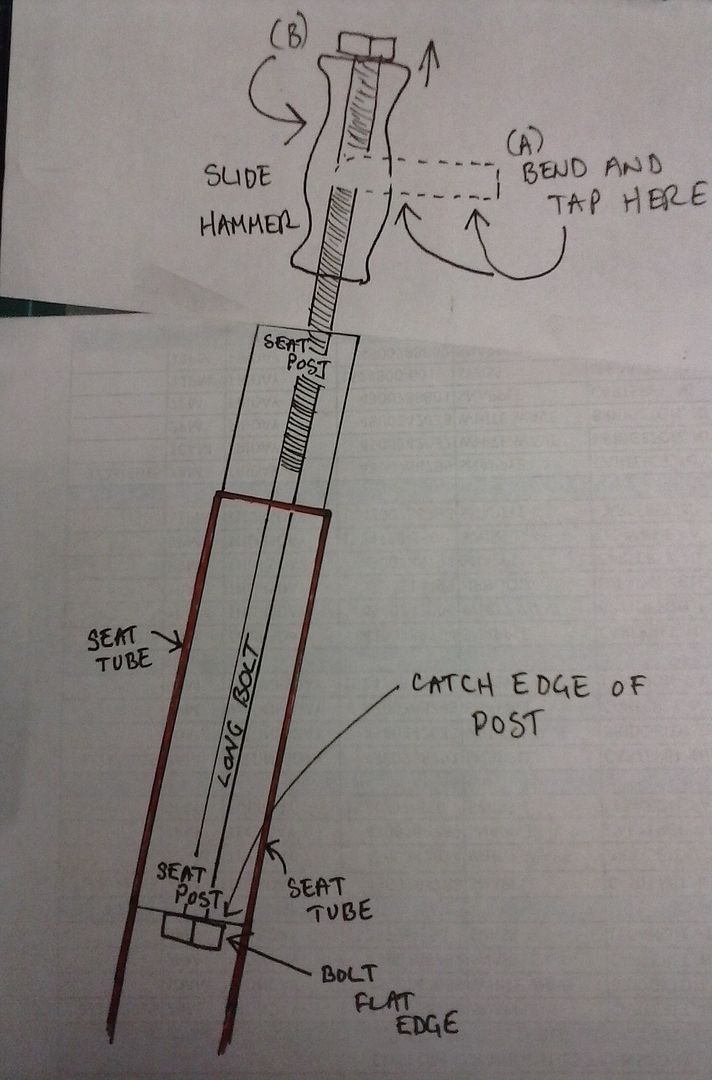

I have a Rockhopper that I bought in the early 90's. The seat post was stuck in the seat tube, but fortunately, it was set pretty darn close to perfect for me. Fast forward to today when I'd like to strip down and paint the frame and I can't get the aluminum seat post out of the ChromeMoly frame. Pipe wrench crushed and twisted the seat post and prying the ears at the top of the tube split the tube a bit. There is still approximately 6" of seat post still stuck in the tube that I can't get to without completely ruining the tube. About the only thing I haven't tried is the caustic soda trick mainly because of my kids and pets around.

I don't have a tig welder, so I'm thinking that cutting out the seat tube and replacing is not a good idea. I do have a flux core welder, but I've heard ChromeMoly will get brittle if you flux core weld it.

The other option would be to cut off the top of the tube and cap it off and mount the seat some how to the crossbar. The saddle I have is a bike store saddle with the two parallel bars.

Pictures of how you did yours or suggestions would be awesome.

I don't have a tig welder, so I'm thinking that cutting out the seat tube and replacing is not a good idea. I do have a flux core welder, but I've heard ChromeMoly will get brittle if you flux core weld it.

The other option would be to cut off the top of the tube and cap it off and mount the seat some how to the crossbar. The saddle I have is a bike store saddle with the two parallel bars.

Pictures of how you did yours or suggestions would be awesome.