I built a shifter tor this bike to fit inside the tank so I figured I'd share what I learned.

The shifter I built is for a Sturmey Archer three speed which has a longer throw between 2nd and 3rd gear than between 1st and 2nd. The throw and related cable mounting dimensions determines the distance the cable travels which is critical to hub operation. So I decided to reverse engineer a shifter I had to get the geometry.

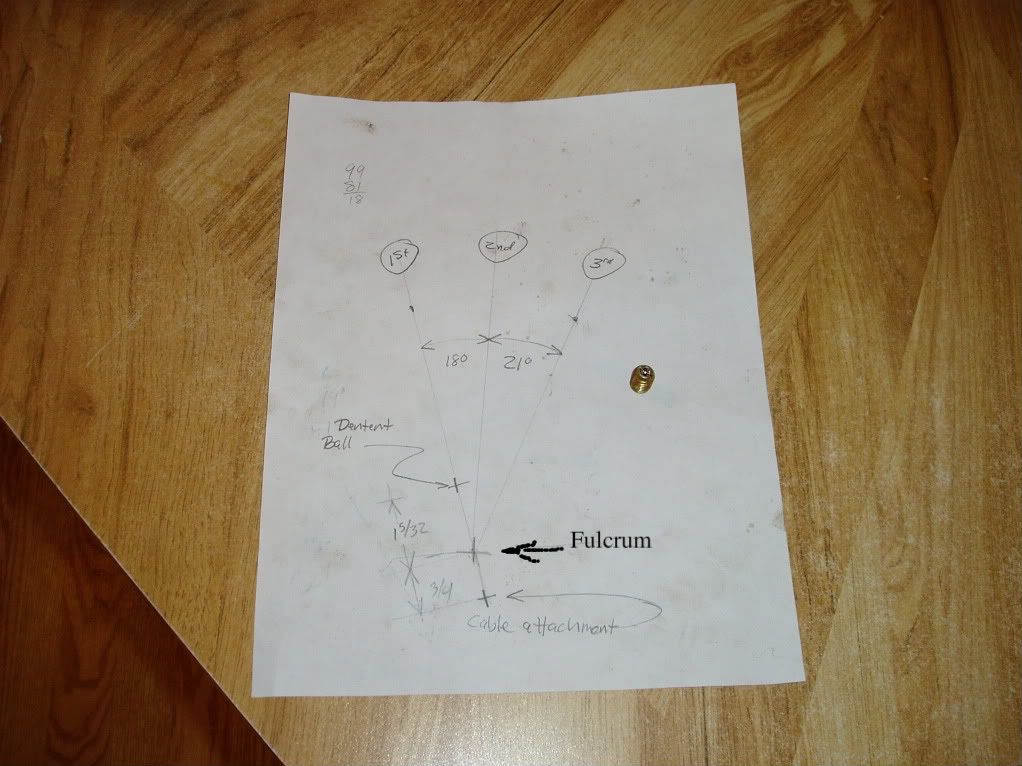

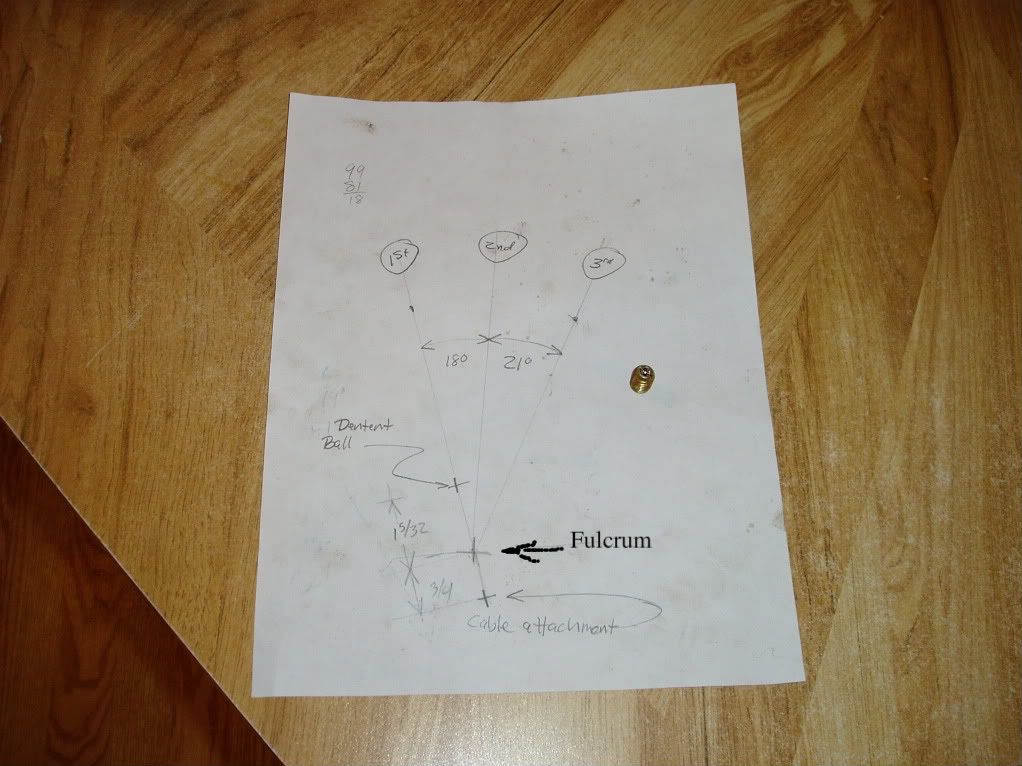

I clamped the shifter on the bench and marked the fulcrum. From there I shifted through the gears and marked the angles of rotation the shifter goes through.

I also measured the distances from the fulcrum to the cable attachment and the detent locations. I made a little sketch that contains all the signifigant geometry for a Sturmey 3 speed hub. The 18 and 21 degrees illustrate the longer throw I refered to. I believe a Shimano will have different geometry.

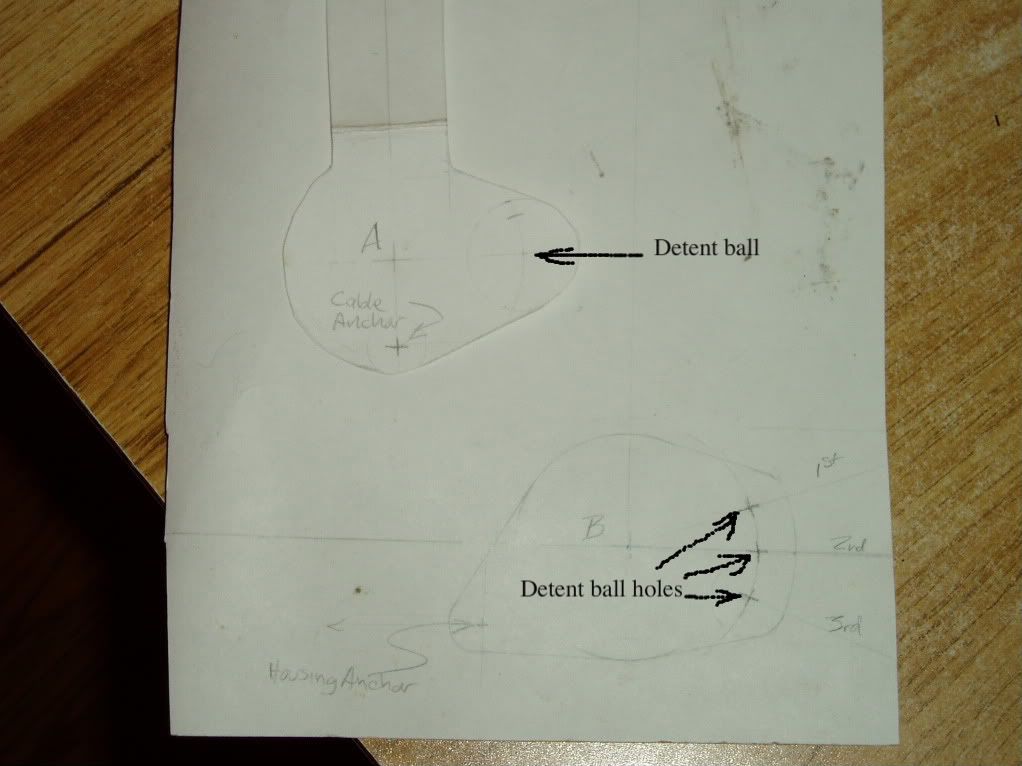

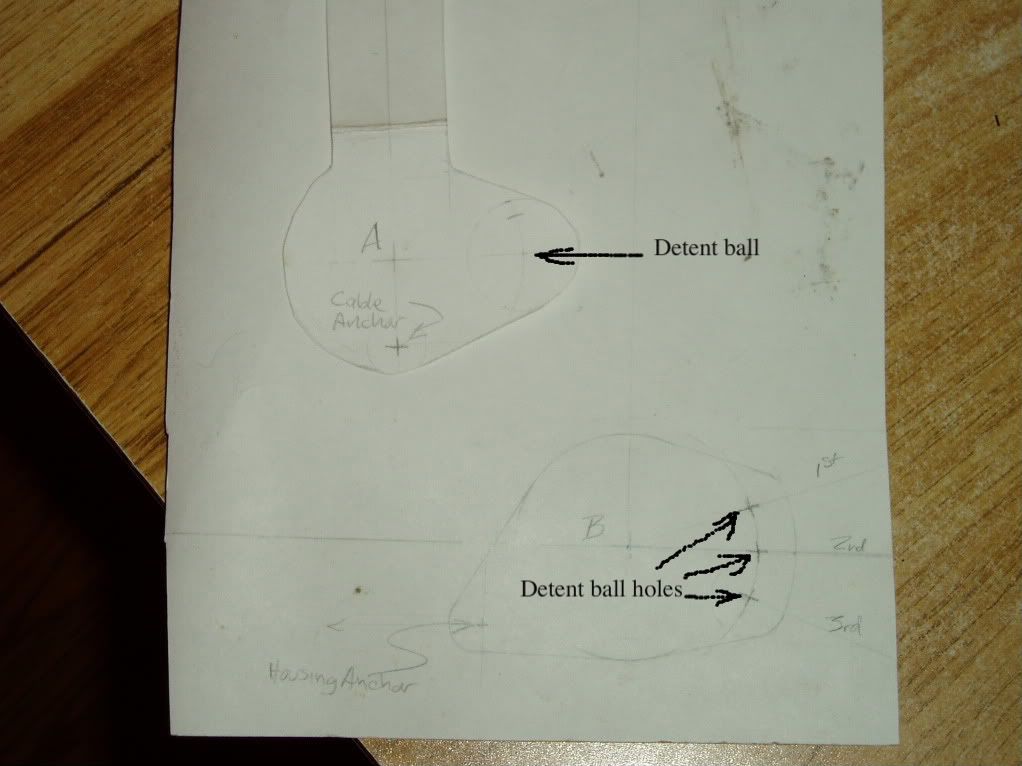

I then laid out the 2 plates needed With the detent ball mounted on the rotating portion and the detent ball holes drilled into the fixed plate that mounted to the frame.

I used a Vlier spring loaded ball plunger that came with 3/8-16 threads so I drilled a hole and welded a nut to accept the ball plunger. I liked this bcause you can adjust the depth by threading it in and out.

Then I welded on a stub to mount my shifter handle on but from here you can use your imagination on yours how to continue.

Vlier sells a variety of spring loaded ball plungers of varying ball diameters, spring pressures and mounting accomidations.

http://www.vlier.com/product_index/sld/bp_00_index.html

Feel free to use the dimensions on the sketches to set yours up. My shifter works great and don't forget you'll also need to come up with rotation stops also. Feel free to ask questions.Good luck!

Here are some more photos.

The shifter I built is for a Sturmey Archer three speed which has a longer throw between 2nd and 3rd gear than between 1st and 2nd. The throw and related cable mounting dimensions determines the distance the cable travels which is critical to hub operation. So I decided to reverse engineer a shifter I had to get the geometry.

I clamped the shifter on the bench and marked the fulcrum. From there I shifted through the gears and marked the angles of rotation the shifter goes through.

I also measured the distances from the fulcrum to the cable attachment and the detent locations. I made a little sketch that contains all the signifigant geometry for a Sturmey 3 speed hub. The 18 and 21 degrees illustrate the longer throw I refered to. I believe a Shimano will have different geometry.

I then laid out the 2 plates needed With the detent ball mounted on the rotating portion and the detent ball holes drilled into the fixed plate that mounted to the frame.

I used a Vlier spring loaded ball plunger that came with 3/8-16 threads so I drilled a hole and welded a nut to accept the ball plunger. I liked this bcause you can adjust the depth by threading it in and out.

Then I welded on a stub to mount my shifter handle on but from here you can use your imagination on yours how to continue.

Vlier sells a variety of spring loaded ball plungers of varying ball diameters, spring pressures and mounting accomidations.

http://www.vlier.com/product_index/sld/bp_00_index.html

Feel free to use the dimensions on the sketches to set yours up. My shifter works great and don't forget you'll also need to come up with rotation stops also. Feel free to ask questions.Good luck!

Here are some more photos.