Hi Ratrodbikers!

I recognize my natural cycles like the seasons. They come and pass, just like this subject.

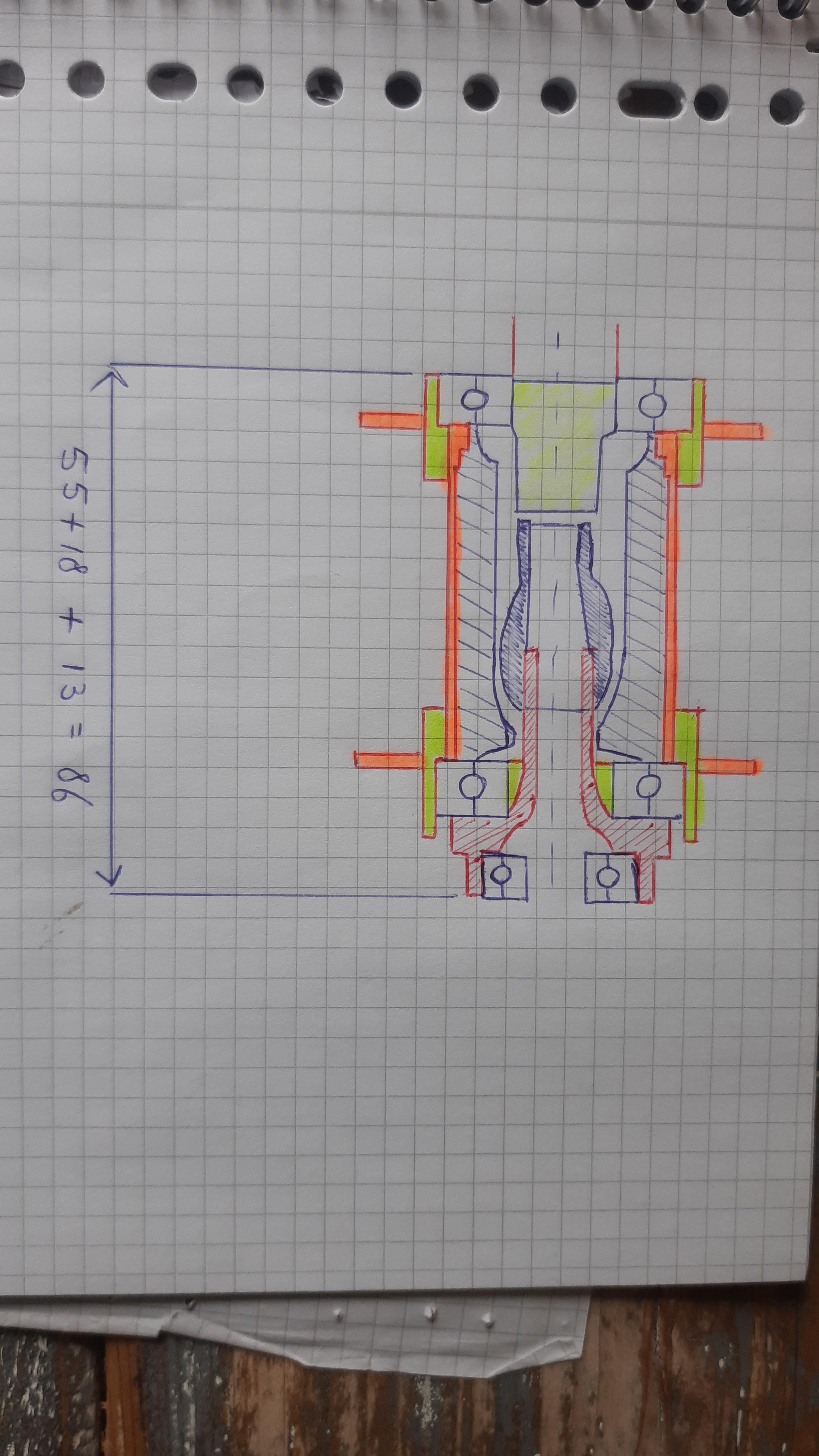

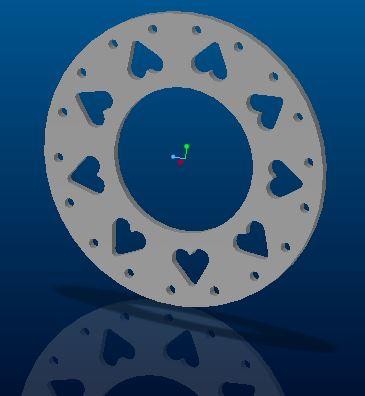

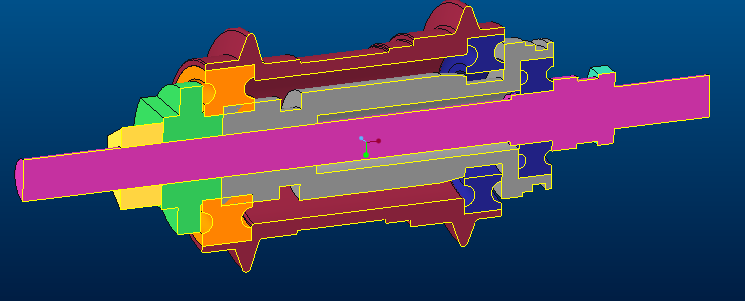

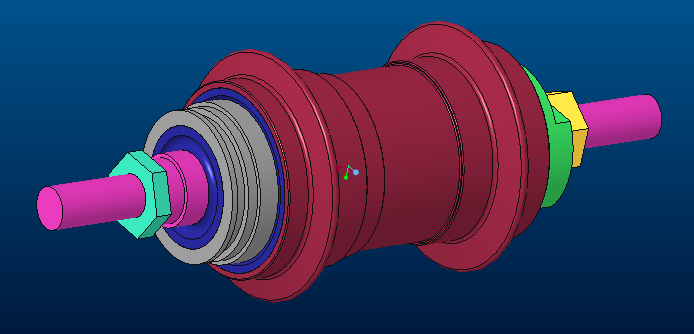

Alright, a while ago I made a design for a Coasterbrake hub with a disc brake. I really enjoyed designing it. Unfortunately I did not fabricate the hub due to time, cost etcetera.

In the months after that, I picked up quite some parts that people tend to throw away: Shimano CB-E110, Velosteel and Favorit (basically the same) shells, drivers and more parts.

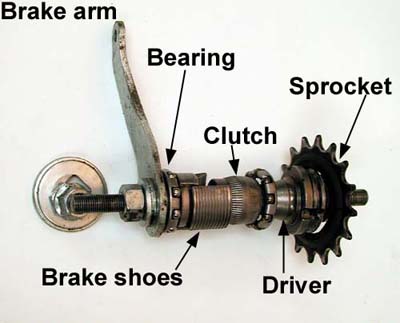

I decided to combine these two types of hubs:

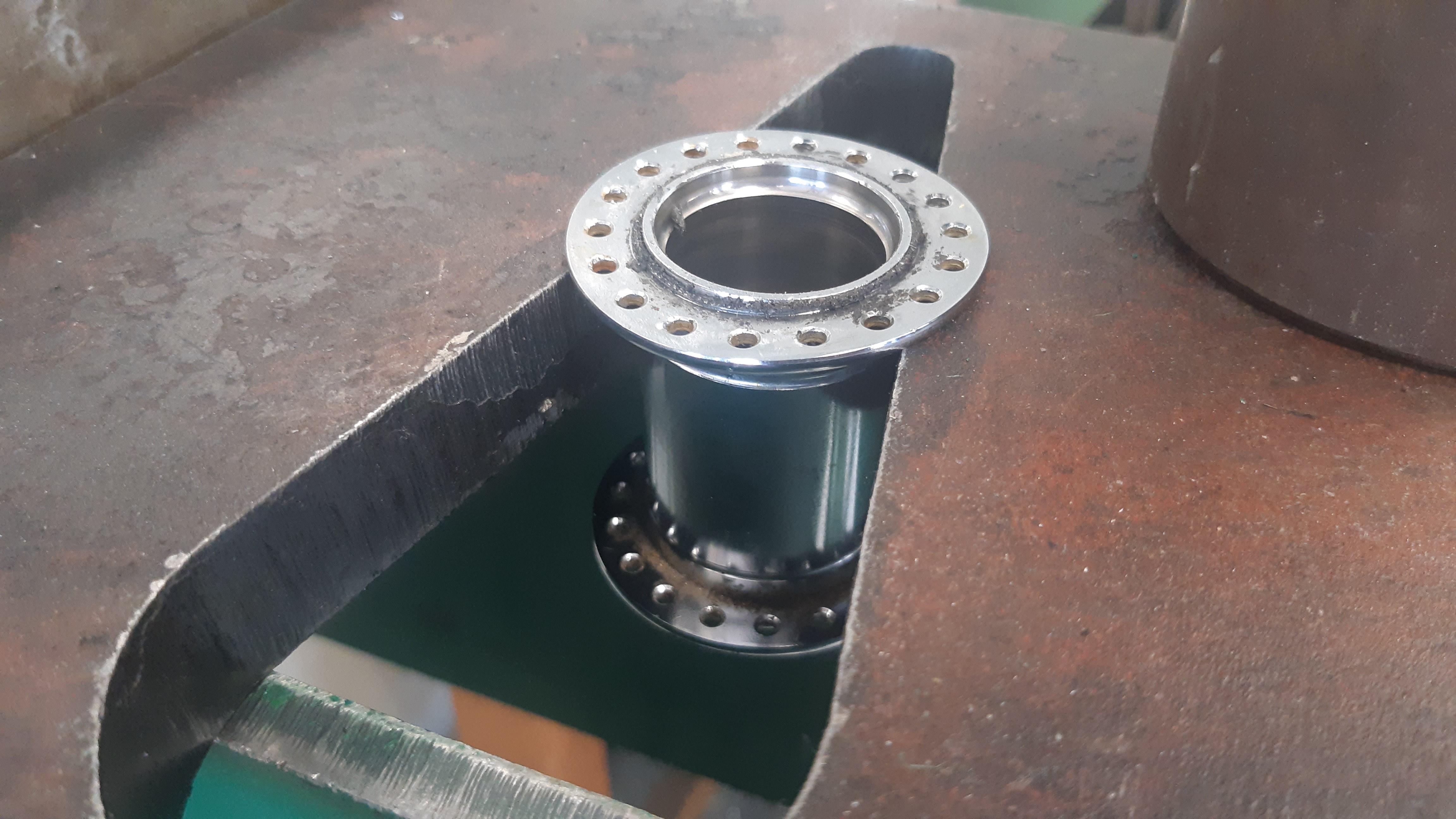

Oh yeah, industrial sealed bearings

I remember industrial sealed bearing lasting a very long time on bicycles.

I found the following bearings to use with above mentioned parts:

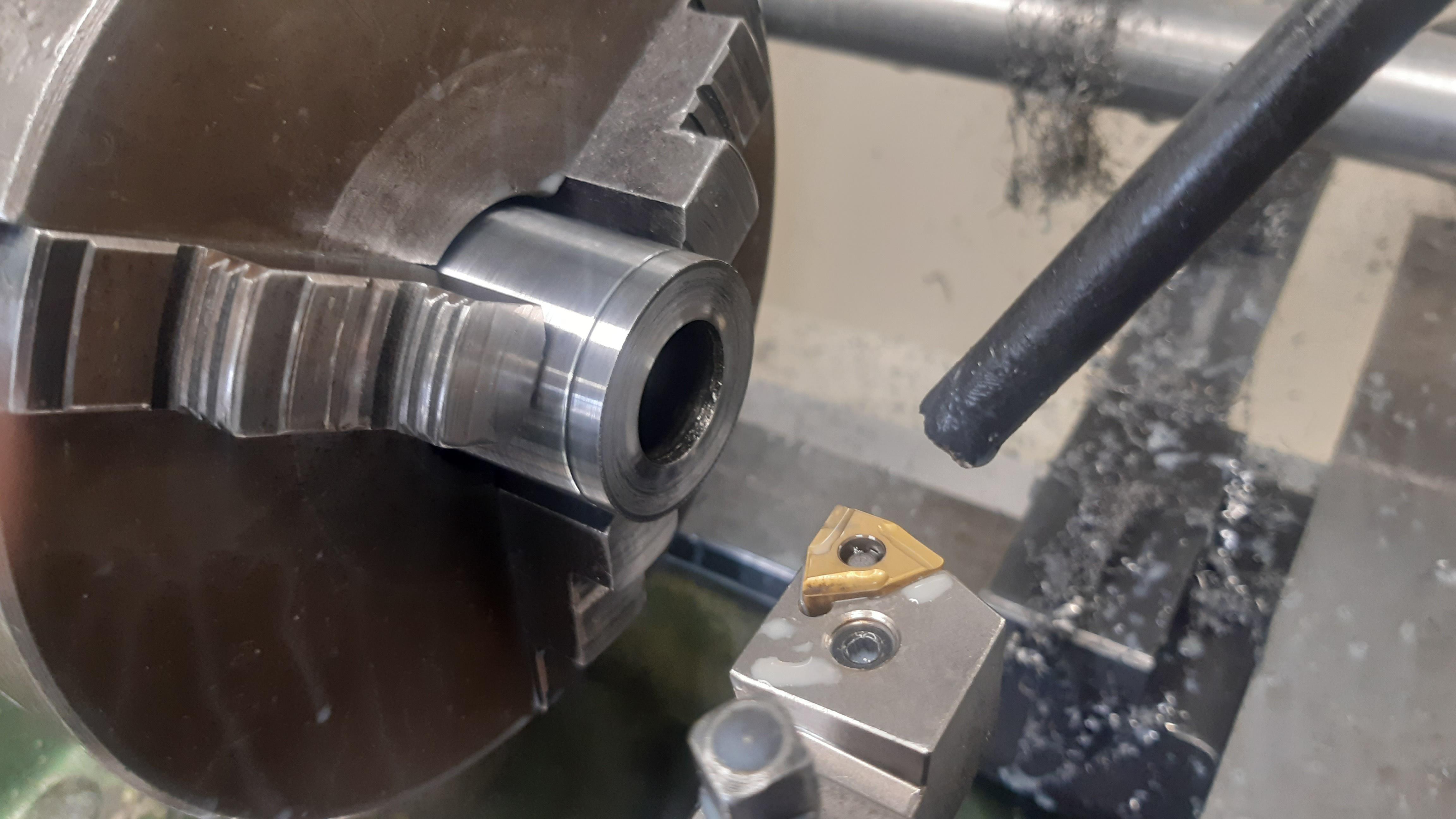

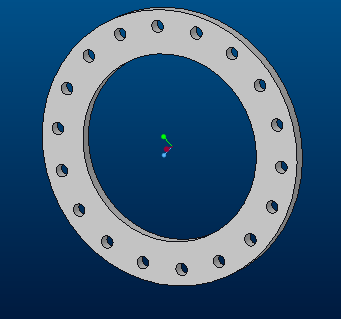

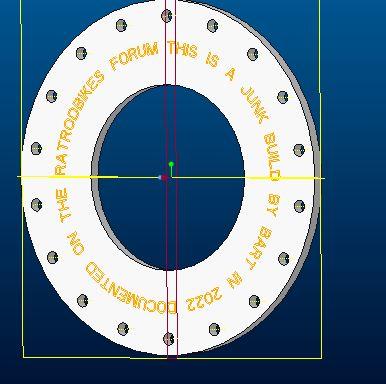

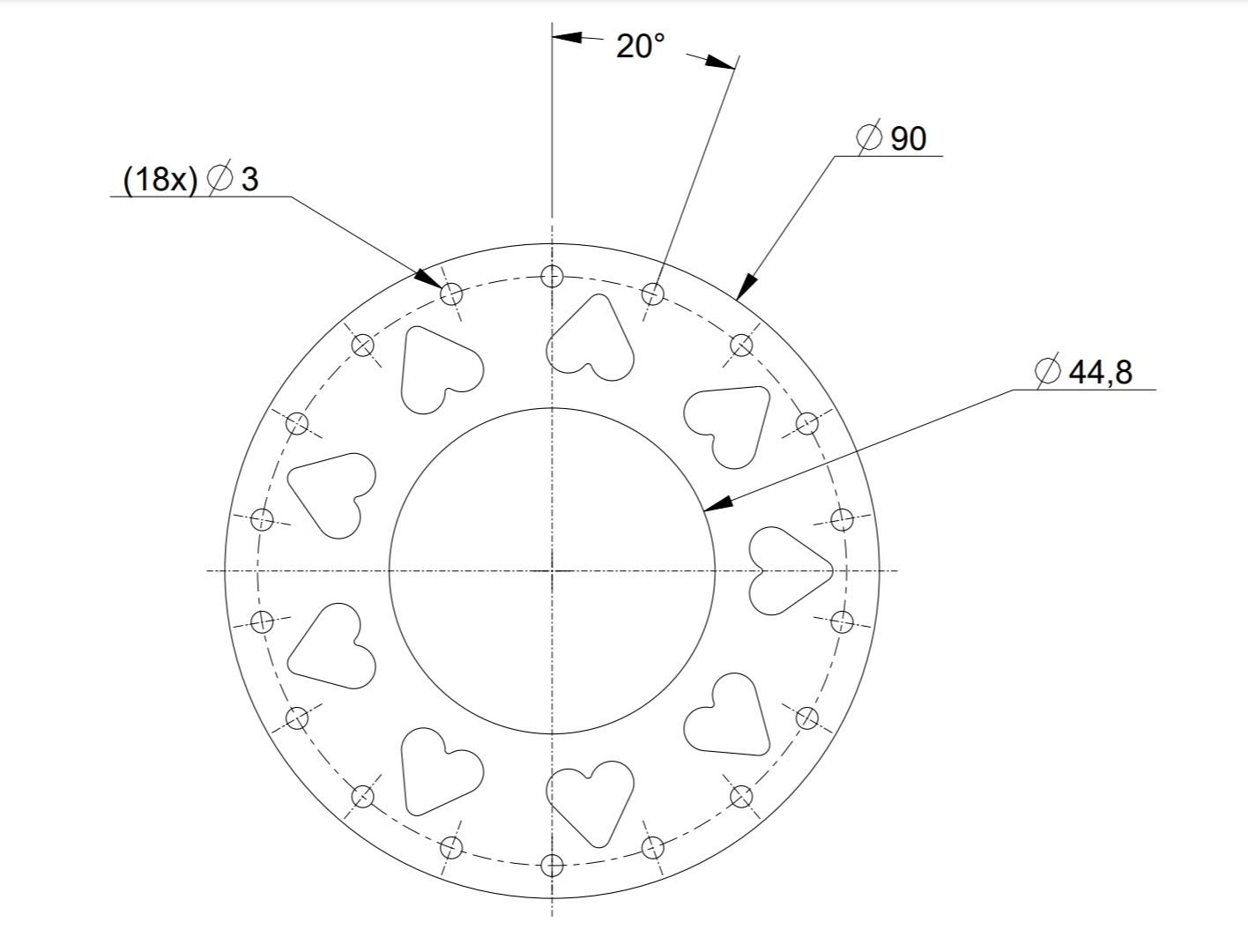

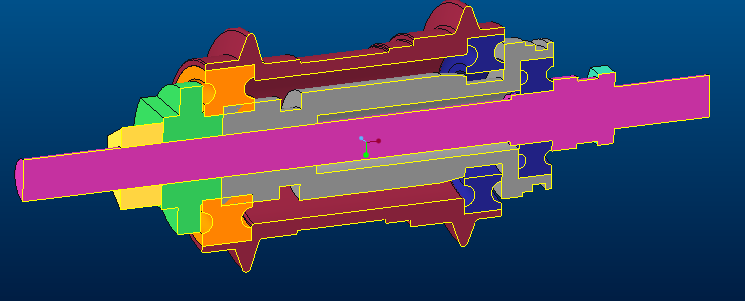

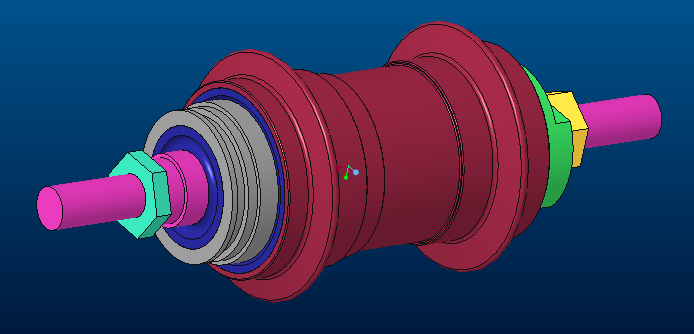

Pictures! Work in progress.

Still parts to be modeled and double-checked in above 3D CAD model.

My goals; to have fun, try a build a almost indestructable hub and share it for the people interested.

If interested, I can share all measurements, drawings, tolerances and steps so you can build this as wel

I love these junk projects.

Question:

Is it wise to powdercoat a hub? I am afraid for: 1: Spokes won't fit through the holes. 2: The coating will break under the pressure, like when you tighten a bolt on paint, the paint will eventually break.

I recognize my natural cycles like the seasons. They come and pass, just like this subject.

Alright, a while ago I made a design for a Coasterbrake hub with a disc brake. I really enjoyed designing it. Unfortunately I did not fabricate the hub due to time, cost etcetera.

In the months after that, I picked up quite some parts that people tend to throw away: Shimano CB-E110, Velosteel and Favorit (basically the same) shells, drivers and more parts.

I decided to combine these two types of hubs:

- Shimano CB-E110 Guts

- Favorit/Velosteel shell

Oh yeah, industrial sealed bearings

I remember industrial sealed bearing lasting a very long time on bicycles.

I found the following bearings to use with above mentioned parts:

- Drive side bearing, between the driver and the shell: KOYO 6905 2RS (42mm - 25mm - 9mm).

- Drive side bearing, between the driver and the M10x1 shaft: SKF 6001 2RS (28mm - 12mm - 8mm).

- Brake side bearing: 6004 2RS (42mm - 20mm - 12mm).

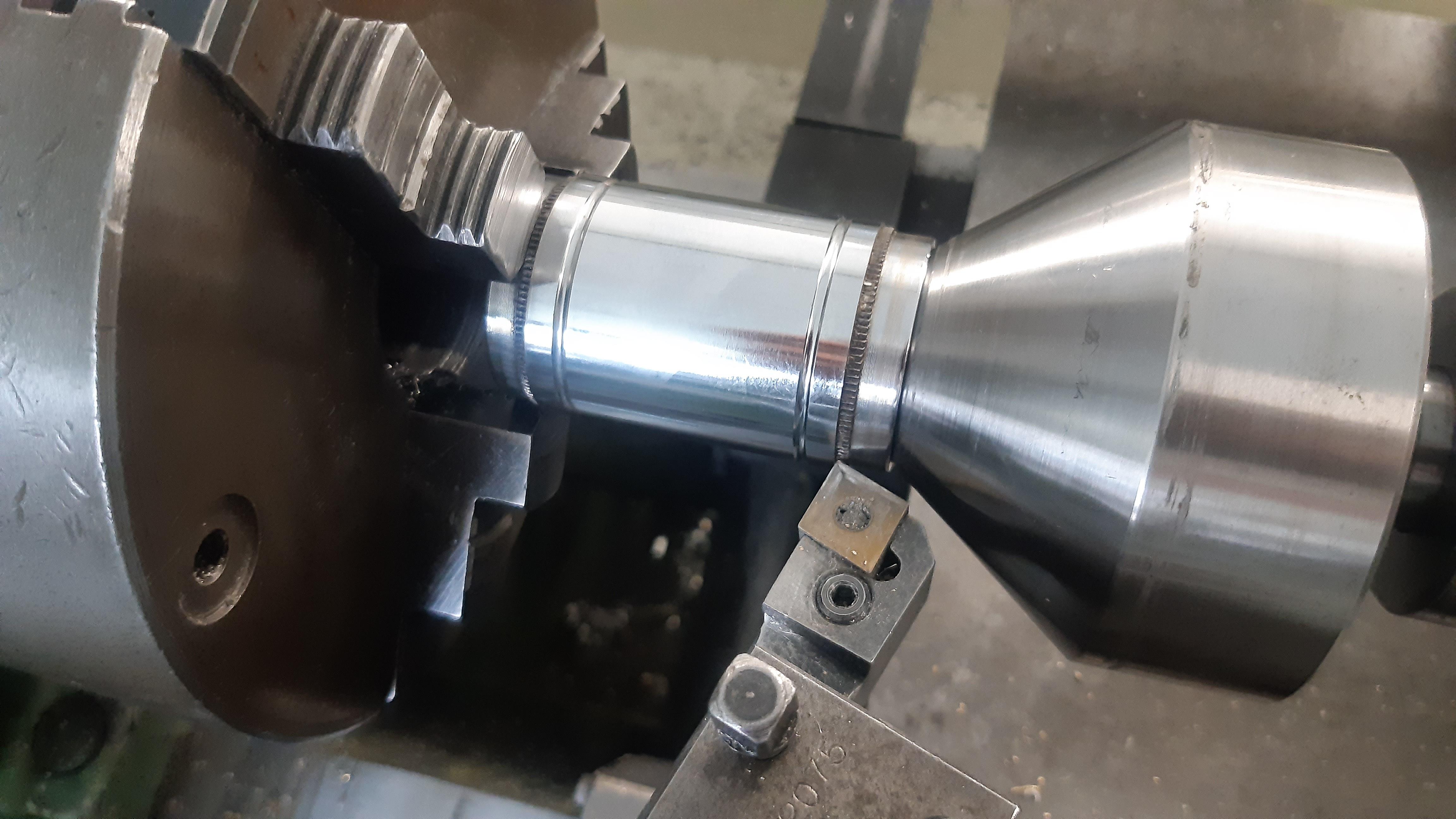

Pictures! Work in progress.

Still parts to be modeled and double-checked in above 3D CAD model.

My goals; to have fun, try a build a almost indestructable hub and share it for the people interested.

If interested, I can share all measurements, drawings, tolerances and steps so you can build this as wel

I love these junk projects.

Question:

Is it wise to powdercoat a hub? I am afraid for: 1: Spokes won't fit through the holes. 2: The coating will break under the pressure, like when you tighten a bolt on paint, the paint will eventually break.

Last edited: