Reminds me of slot car racing days. We used heat sinks to dissipate heat from the resistor. Bart, your Hub/brake is a work of art.

Update on this hub:I found some more CB-E110 hubs since people tend to throw bicycles away with a rusty chain.

I disassembled a hub. Looks perfectly fine! No wear whatsoever. Just some surface rust on the shell.

I decided to have fun with this one as well!

I removed the hub flanges with a press (fairly easy).

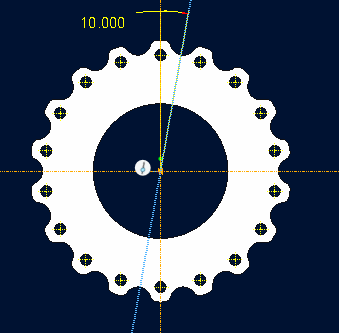

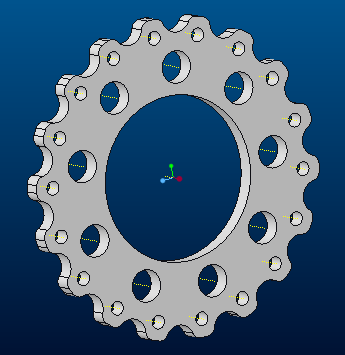

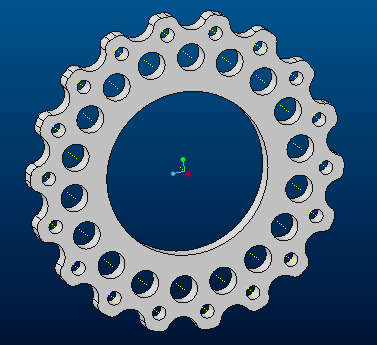

I want to press on some aluminium or steel hub flanges I modeled and cut.

Have to admit, the flange geometry idea/inspiration came from the "Mone cycles" version of the Shimano coasterbrake hub.

9 speedholes.

18 speedholes.

Mone cycles hub with heatsink.

I am not building a heatsink since the Netherlands is flat!

Yes is the answer:Do you have access to a CNC mill, or some kind of indexing head?

This is terriffic, sir. Thoughts of buying ready-made flanges were never imagined or enjoyed here. Wher... I say, WHERE might such to be found? With a few in my grimy hands, I could potentially swap existing hub flanges to match higher spoke-count rims. Si?Thanks a lot guys! Its kinda busy with two kids now, but everyone will have to get used to the Chopper.... ehh to the baby

Moeder is doing great and really taking good care of Thura. I am taking care of our two year old daughter most of the time now.

During the "kraamweek" we had help from a "kraamverzorgster". A nice lady that helps with the baby's and moms health (checking weight, temperature and milk intake) and with some chores around the house. This is normal in the Netherlands where you get help for a week.

Unfortunately I could not convince the lady to make a mockup with the chopper frame

I'll make a thread soon.

Is this also common in the US or Canada? Where you get this kind of help the first week?

I did have some time to look for junk on the interwebs and found some hubs for 2 euros. They are from kids bikes, but almost new!

One is a 28 hole 1985 F&S Torpedo hub.

The other a F&S replica by Romet with less holes (I think a Polish buildoff participant mentioned this brand of hub/bike).

I ordered two extra hub flanges for this hub, so its 36 hole too! I can bolt or rivet the flanges or that hub.

And I could not resist buying a 50's US wheelset with bendix hub: (Uncommon in the Netherlands)

Bought it from "bikestoremember.nl". They have some "New Departure model D's" with skip tooth as well. Including complete wheelsets.

I don't know for which build I will use this set, maybe I will take a bike apart and build something new.

Thinking to take apart my green Electra RS Klunker and put this set on the frame and store it for a future buildoff....

Use the 26 inch Klunker wheelset for the chopper....

Also toying with the idea of throwing the chopper in the yard (with grease inside the frame) for a rat build. The frame is almost the same as the Nirve Cannibal/Switchblade.

In the coming months I will have time for a mockup and rearreangement of parts/bikes.

Thanks again!

Thank Ulu, I love machine shop work too!I’m suffering an acute attack of machine shop jealousy right now. I used to do all this stuff in the hobby shop at the Air Force Base, but now I’m in the situation with no machine tools available.

Edit…I never built a hub, btw, but I did build things like custom shifters and daggers and special pulleys so I could make high speed tape recordings back in the reel-to-reel days.

Thank you! I am happy to make an STEP file or DXF file so you guys can contact your own lasercutter or waterjet supplier.This is terriffic, sir. Thoughts of buying ready-made flanges were never imagined or enjoyed here. Wher... I say, WHERE might such to be found? With a few in my grimy hands, I could potentially swap existing hub flanges to match higher spoke-count rims. Si?

Good question, there are pearl-blasting operations with a similar effect aswell. I don't have the answer unfortunately.I wonder if a rock-tumbling type operation would polish-up the rougher edges, (or might ruin it?).

Again; good question, will ask around and consider it.It could be polished in a vibratory tumbler like spent brass. It’s not to big to hand polish on the lathe though. So far I haven’t tried the vibratory tumbler on any bicycle parts.

I read that these 'no-band' Bendix hubs were made between 1946 and 1963, but I can't find the piece I read again unfortunately.I have an early Bendix hub also. I've read where Bendix began making coaster hubs in 46. Is there a way to know the year the Bendix was made? Number code?

Thanks Tallbikeman, I think you read the post from 2022, but my kids are still a blessingCongratulations on your daughter. Children are a blessing.

Enter your email address to join: