c.p.odom said:

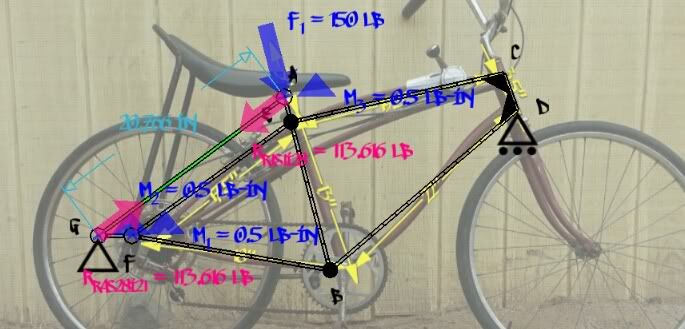

Sure; It is called FEA (Finite Element Analysis). This is software that runs off of the 3D solid CAD models. You can run this as a static or dynamic test. The requirements are : an engineering workstation (computer), high end CAD program, FEA program, and it helps to have at least a BS in mechanical engineering.

Hey, I have (or have access to) all of those things! In fact, I'll be in Cincinnati in 2 weeks for training on using the FEA program we bought.

But at the end of the day, while the "jumping on the lightest one and see if its holding" is a bit sketchy to me, there really isn't a huge amount of load when you're dealing with just casual riding. Yes, the old overbuild school of thought works, and if something does give out, you have an excuse for an upgrade. But if it came to dealing with bikes that see extreme loads - downhill MTB, cyclocross, track events, etc, then I'd think you want to be a bit more careful with your calculations...