Hi guys,

I started my crossframe build in the "Barts Eternal Builds" thread, but considering I will be fabricating more stuff I decided to give this (slow) build its own thread.

First the bike:

The story:

I have been looking for a crossframe/pastors bike for some time now and they are not hard to find! But I have certain design wishes that is/are not available on the market:

(Also checkout the Azor IFL for fun purposes)

But this frame has a "relaxed" seating position with a 67 degree seat tube angle.

So I decided to build my own frame with the features that I like on a bicycle:

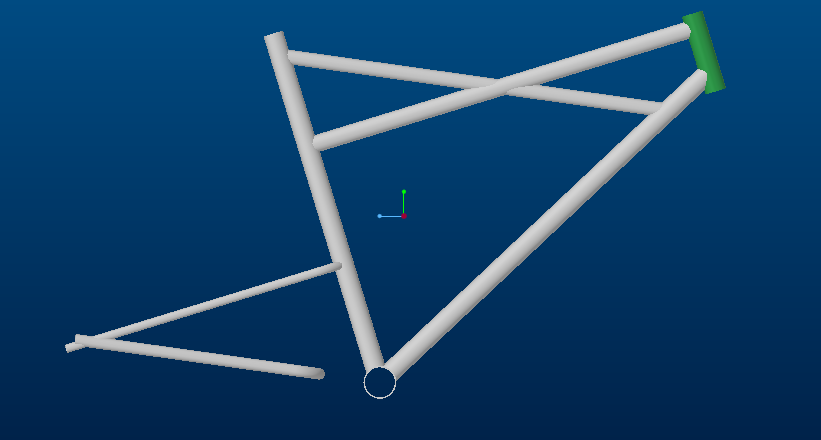

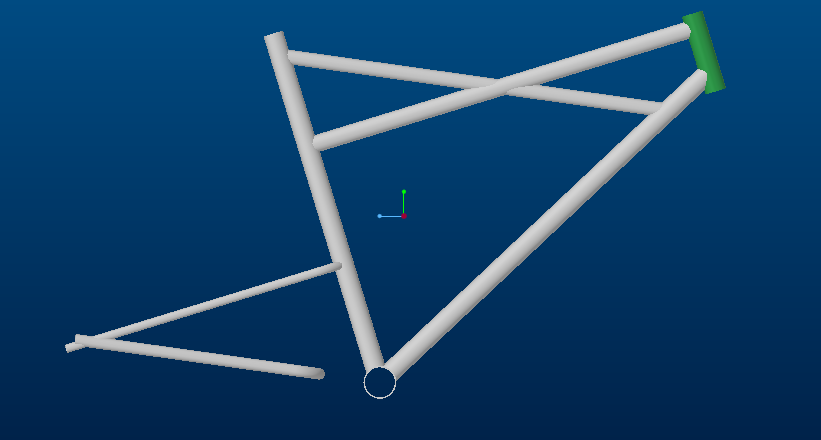

I made a CAD design, cut the tubes and made a simple frame JIG. Pictures below:

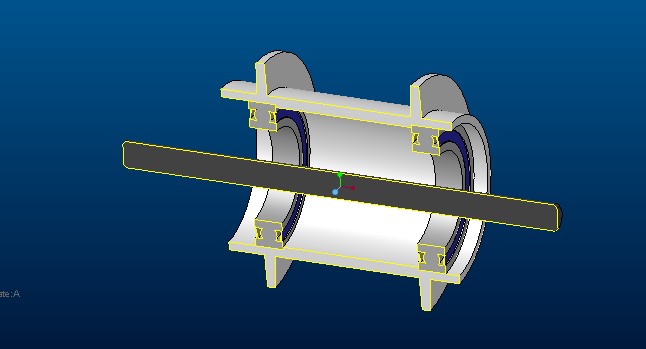

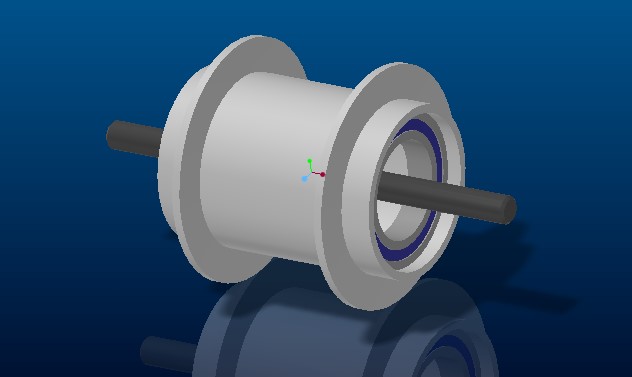

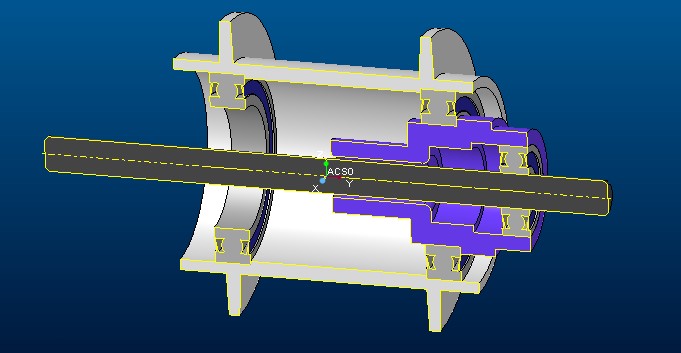

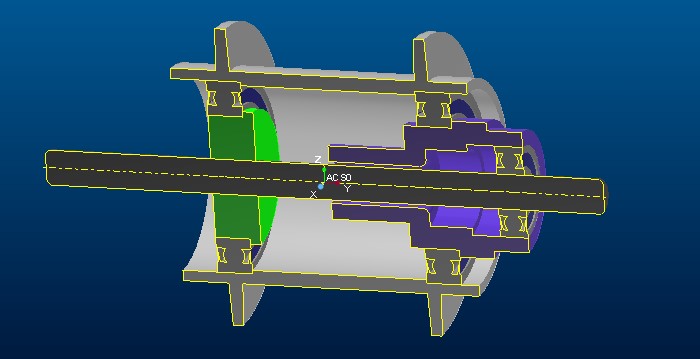

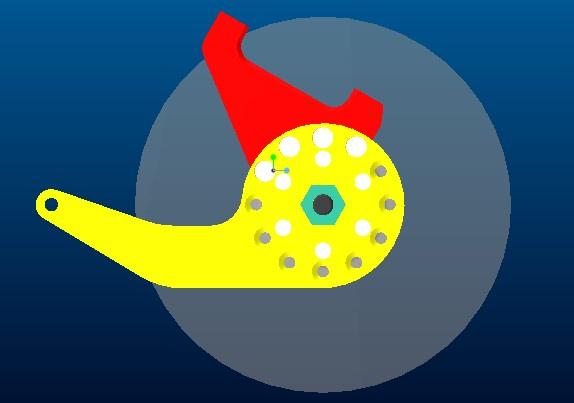

Unfinished CAD model.

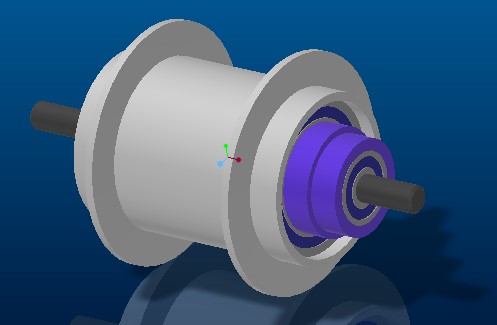

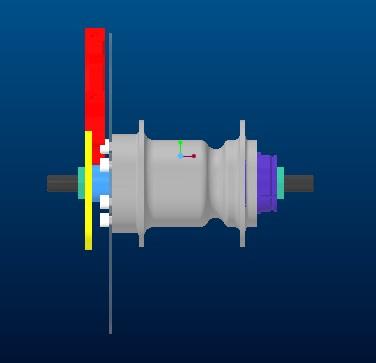

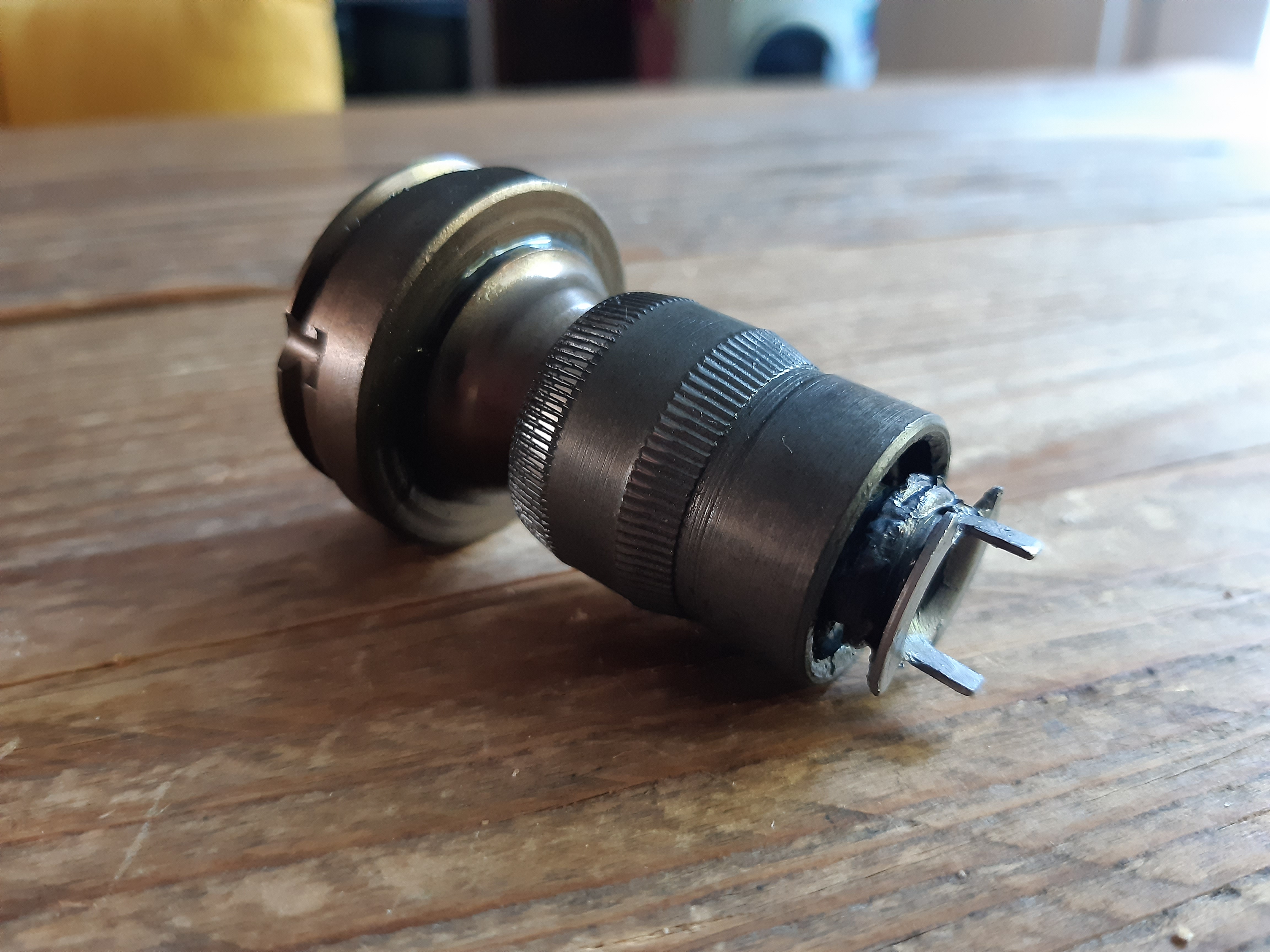

Crank for mockup purposes: I can use this and fabricate a rubber seal to keep out dirt.

Frame tubes partially cut, bend and tossed on the floor.

And the coasterbrake:

Always loved coasterbrakes, BMXed with them as a kid and forgot them for many years...

Now having seen the "Hack bike derby", after that the "Coasterbrake challenge" and discovered Klunking (and commuting with a singlespeed coasterbrake bicycle) I started appreciating them again.

Having cycled with the Shimano CB-e110 and klunking with the Sturmey Archer S1C, I am starting to find out what makes them so great and what the flaws of the current available hubs are...

Most modern hubs are based on old hub principles... not that that's a bad thing!

But the main thing I dislike is this maintainance part: Sand in the bearings because of inadequate dust caps. I had to repack a CB-e110 hub because of this about every two months. While cycling with a "industrial bearing" Sturmey Archer X-RDC took me years to break it.

I decided to design a new coasterbrake hub with the following (goal) features:

First, inspiration:

Klunking, Repack, Coaster brake challenge.

Investigation:

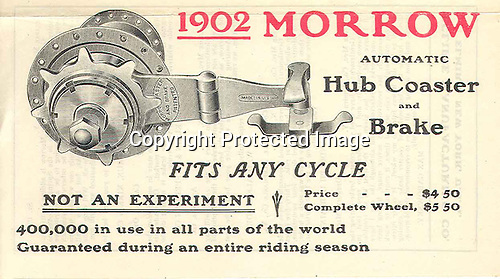

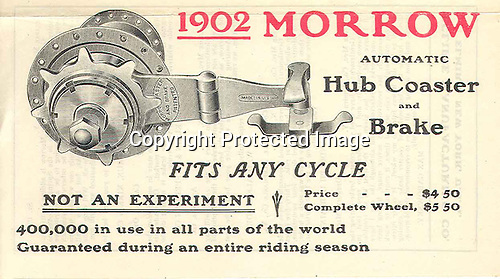

I looked a old hubs and workings: Morrow, New departure, Favorit, Bendix, simplex cycloide (not a coasterbrake, but industrial bearings!).

That coaster arm, great idea make it available for all frames "fits any bicycle")

Inner workings of a "Velosteel" hub.

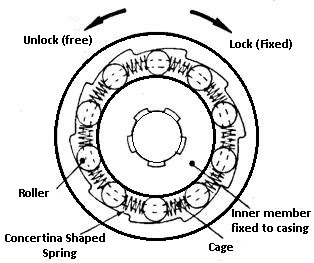

Principle with balls!

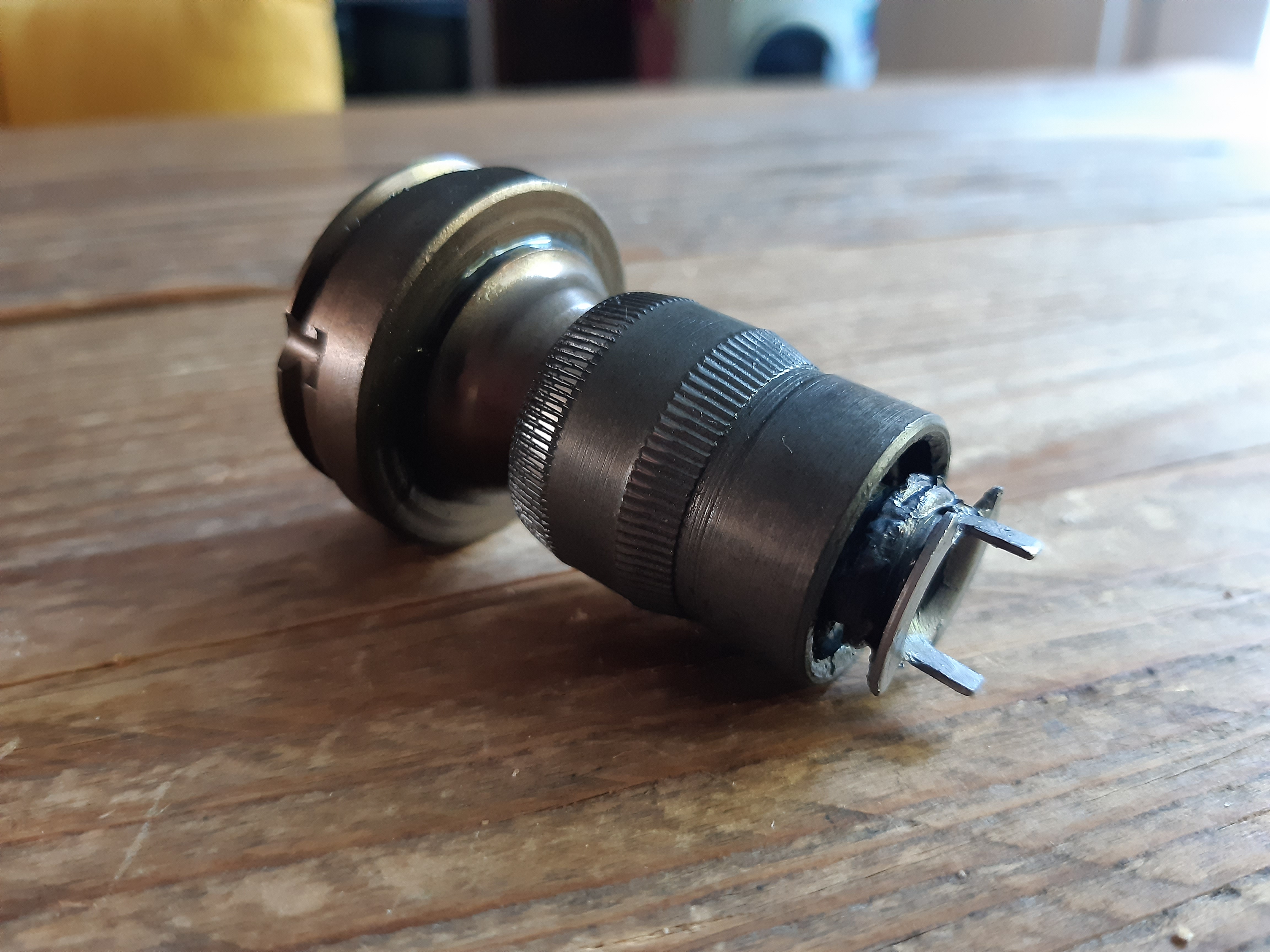

Shimano driver and clutch.

Interesting design, it has "multi cycle thread" so that the axial displacement will be greater with each turn!

After disassembling various hubs and checking the (in my opinion) pros and cons:

Shimano CB-E110:

What does a coaster brake hub do?

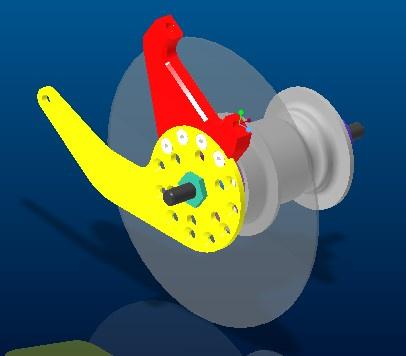

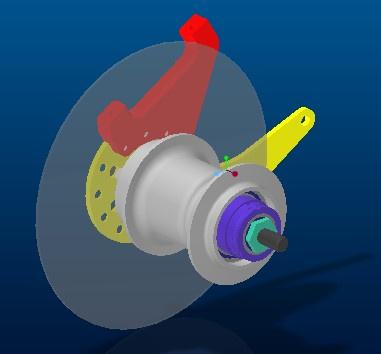

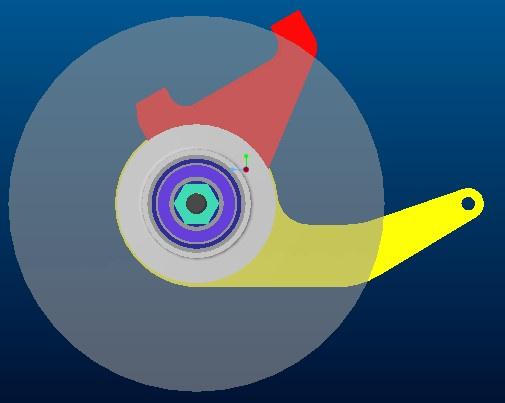

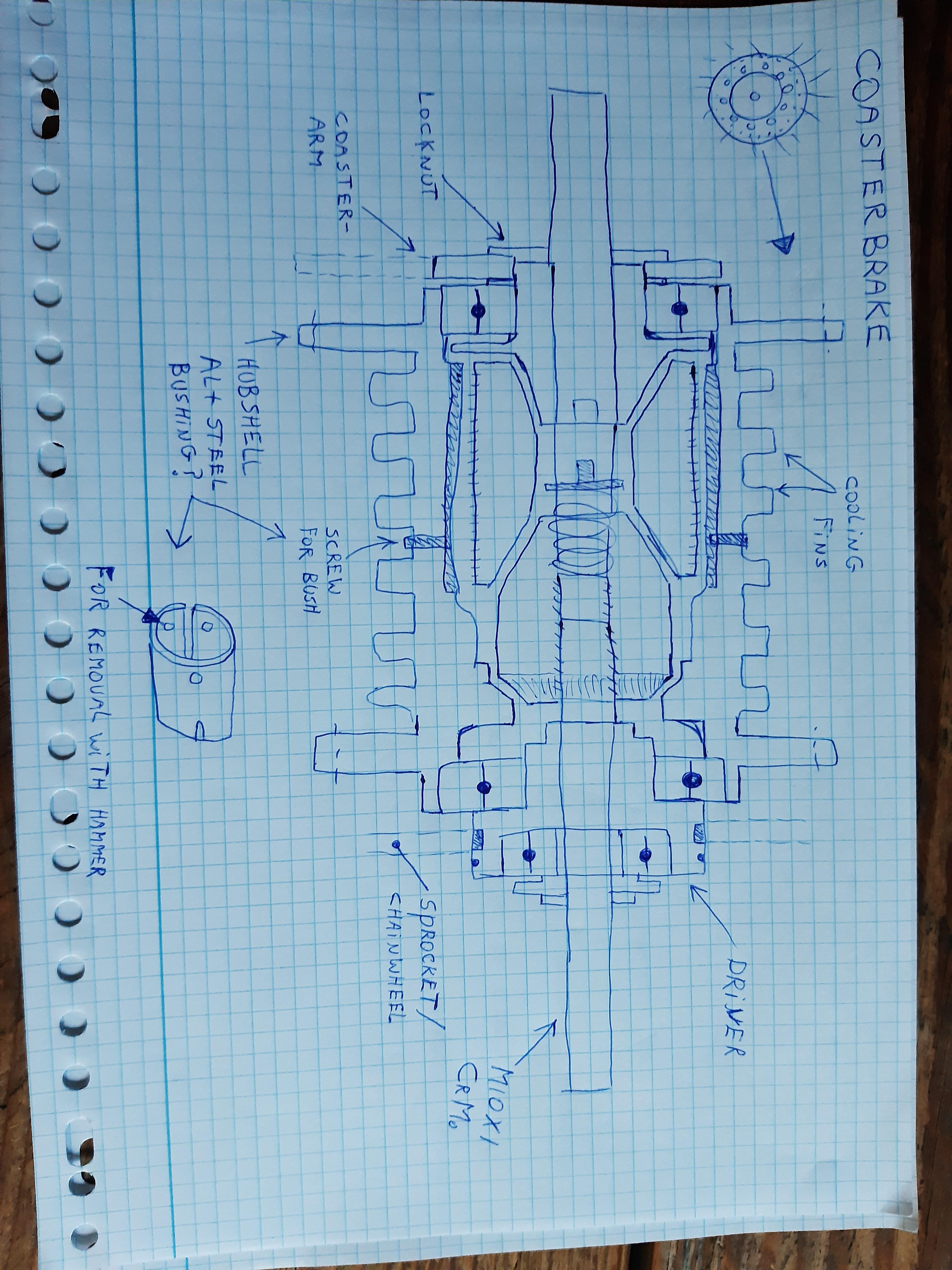

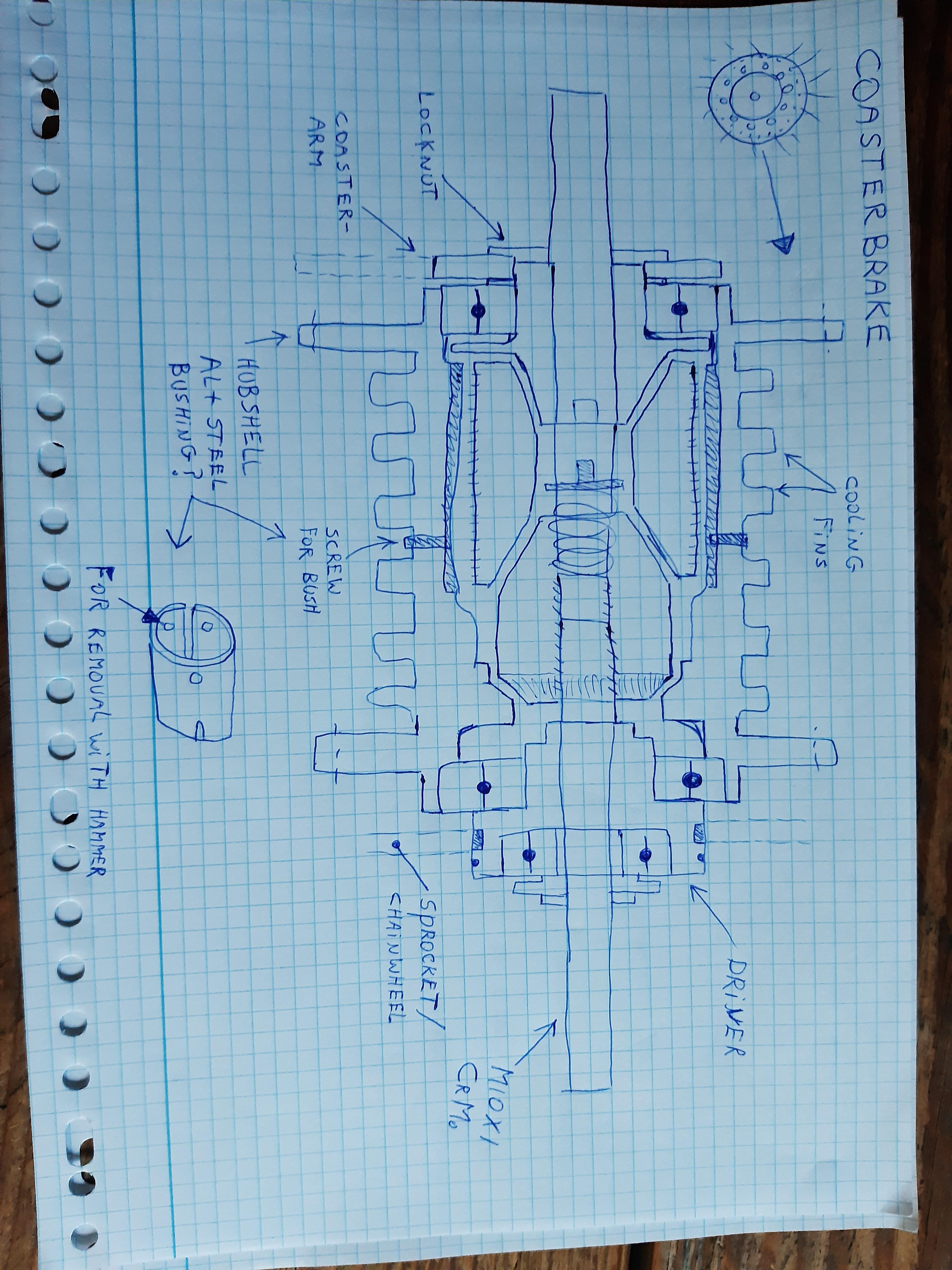

After all this information searching drawing ugly sketches a first 'good' concept drawing came out:

This is a very rough concept! I have much more designs up my sleeve

If there are questions, just ask them!

I started my crossframe build in the "Barts Eternal Builds" thread, but considering I will be fabricating more stuff I decided to give this (slow) build its own thread.

First the bike:

The story:

I have been looking for a crossframe/pastors bike for some time now and they are not hard to find! But I have certain design wishes that is/are not available on the market:

- Around 73 degree seat tube angle.

- Fat 28/29inch tires.

- Steel cross frame.

- Horizontal dropout.

(Also checkout the Azor IFL for fun purposes)

But this frame has a "relaxed" seating position with a 67 degree seat tube angle.

So I decided to build my own frame with the features that I like on a bicycle:

- CroMoly tube cross frame. (Lugging a frame was not an option unfortunately).

- Around 73 degree seat tube angle.

- 29+ tires.

- Surly ECR 29+ front fork with all its possibilities.

- Horizontal dropout.

- Ashtabula bottom bracket/single piece crank. Or a three piece BMX version.

- Coasterbrake rear hub.

- Near indestructable

I made a CAD design, cut the tubes and made a simple frame JIG. Pictures below:

Unfinished CAD model.

Crank for mockup purposes: I can use this and fabricate a rubber seal to keep out dirt.

Frame tubes partially cut, bend and tossed on the floor.

And the coasterbrake:

Always loved coasterbrakes, BMXed with them as a kid and forgot them for many years...

Now having seen the "Hack bike derby", after that the "Coasterbrake challenge" and discovered Klunking (and commuting with a singlespeed coasterbrake bicycle) I started appreciating them again.

Having cycled with the Shimano CB-e110 and klunking with the Sturmey Archer S1C, I am starting to find out what makes them so great and what the flaws of the current available hubs are...

Most modern hubs are based on old hub principles... not that that's a bad thing!

But the main thing I dislike is this maintainance part: Sand in the bearings because of inadequate dust caps. I had to repack a CB-e110 hub because of this about every two months. While cycling with a "industrial bearing" Sturmey Archer X-RDC took me years to break it.

I decided to design a new coasterbrake hub with the following (goal) features:

- Sealed industrial bearings.

- Simple and require no special tools to maintain.

- Better cooling than existing hubs (have to put this in numbers, or just test (smoke) hubs).

- 120mm width for dropouts.

- Same range in weight as existing hubs.

First, inspiration:

Klunking, Repack, Coaster brake challenge.

Investigation:

I looked a old hubs and workings: Morrow, New departure, Favorit, Bendix, simplex cycloide (not a coasterbrake, but industrial bearings!).

- Current available hub: Shimano CB-E110 (almost same mechanics as the Bendix Red Band).

- Current available hub: Velosteel (same working as the "Favorit" hub).

- Current available hub: Sturmey Archer S1C (Ratchet/rollerbrake hub, great stopping power!).

That coaster arm, great idea make it available for all frames "fits any bicycle")

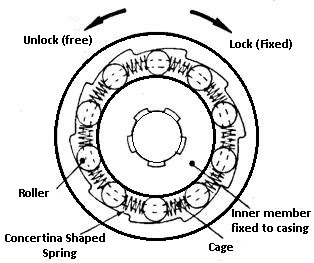

Inner workings of a "Velosteel" hub.

Principle with balls!

Shimano driver and clutch.

Interesting design, it has "multi cycle thread" so that the axial displacement will be greater with each turn!

After disassembling various hubs and checking the (in my opinion) pros and cons:

Shimano CB-E110:

- Pros: Simple design, reliable, very good bearing races, clutch design which does multiple tasks, tough shell, relatively cheap to buy, spare parts plenty available, very easy to service).

- Cons: Cup and cone bearings (if you compare them with the efficiency of industrial bearings), inadequate dust caps, not much surface area for cooling/steel shell?

- Pros: Tough design, large brake pads, good quality internal parts.

- Cons: Brakes can lockup with the roller ball design and the roller ball design within the brake pads actually turns when you are pedalling the bike, which causes friction.

- Pros: Good quality parts! Looks good, great stopper (skidding) power, aluminum hub shell, dust caps are better than previous hubs.

- Cons: Less simple parts and less standard, so more difficult to fix when the sh*t hits the fan, requires more 'special' tools to completely overhaul.

What does a coaster brake hub do?

- Pedalling: Driver and cog moves forward, takes the hub shell with it.

- Coasting: Hub shell runs free. No braking, no pedalling.

- Braking: Pedal backward, the brake is initiated, the brake pads move outward against the hub shell lining and creates friction.

After all this information searching drawing ugly sketches a first 'good' concept drawing came out:

This is a very rough concept! I have much more designs up my sleeve

- It features the same cone-clutch as the Bendix and Shimano.

- It features the same brake pad design as the Bendix red band.

- Industrial bearings (did some market research). The most difficult part is: Cup and Cone bearings do not require much space compared to industrial ones.

If there are questions, just ask them!

Last edited: