Hey does anyone know how to weaken the spring on a set of rat trap forks? Mine are pretty solid and I thought about trying to cut the spring down but didn't know if there was anything easier someone had come up with.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rat Trap adjust

- Thread starter thebearded1

- Start date

Help Support Rat Rod Bikes Bicycle Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

There is a way based on tempering of the steel. Since doing it at home is not finely controled and the grade of steel used for the spring is unknown the outcome is unsure so I would recomend incremental trial and error.

Put the spring in a preheated oven, say start at 150 degrees Centigrade for 15 mins, take out and let it cool naturaly in the air. Check the spring tension and compare it to measured tension before treatment.

If no or little change then repeat for 30 mins. Again if no change repeat increasing the oven temperature to 180 degrees centigrade. You should get the idea. Remember that the chrome plate will start to tarnish as the temperature increases, at first this can be polished out but at some point depending on the quality of the chrome you may have permenantly tarnished finish. This is unusual in my experience at temps below 200 degrees C.

If you go to far the steel may become anealed and will be useless as a spring so be careful!!

Put the spring in a preheated oven, say start at 150 degrees Centigrade for 15 mins, take out and let it cool naturaly in the air. Check the spring tension and compare it to measured tension before treatment.

If no or little change then repeat for 30 mins. Again if no change repeat increasing the oven temperature to 180 degrees centigrade. You should get the idea. Remember that the chrome plate will start to tarnish as the temperature increases, at first this can be polished out but at some point depending on the quality of the chrome you may have permenantly tarnished finish. This is unusual in my experience at temps below 200 degrees C.

If you go to far the steel may become anealed and will be useless as a spring so be careful!!

I wish mine was stiffer!! :lol:

maybe you guys could trade springs. :idea:scrumblero said:I wish mine was stiffer!! :lol:

KJV said:maybe you guys could trade springs. :idea:scrumblero said:I wish mine was stiffer!! :lol:

naw, its just cause i'm 300# :lol:

$19.99

Electra Glide Wall Decal 2ft Long Sport Harley Davidson Bike Motorcylce Sticker Man Cave Garage Boys Room Decor

FatCat Wall Graphics

$251.73

$319.99

Kulana Lakona Tide Adult Beach Cruiser Bike, 26-Inch Wheels, 7-Speed, Silver

Amazon.com

Ha ha ha perhaps a trade should be in order scum but they could be the same since i'm a lightweight lol.

I may try the heating technique wolf thanks for the idea. I'm not really worried about the tarnishing since she is a rat.

I did that as well udall and love the look but didn't get much more spring out of it. It also threw my steering off quite a bit too which took some getting used to.

I may try the heating technique wolf thanks for the idea. I'm not really worried about the tarnishing since she is a rat.

I did that as well udall and love the look but didn't get much more spring out of it. It also threw my steering off quite a bit too which took some getting used to.

Flipping the rockers will have drastic effect on the steering, as on udallcustombikes' above, because it changes the steering geometry to give tire contact patch lead (negative trail).

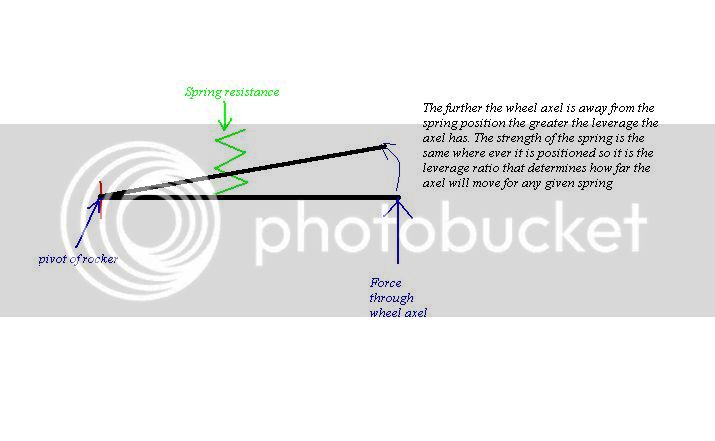

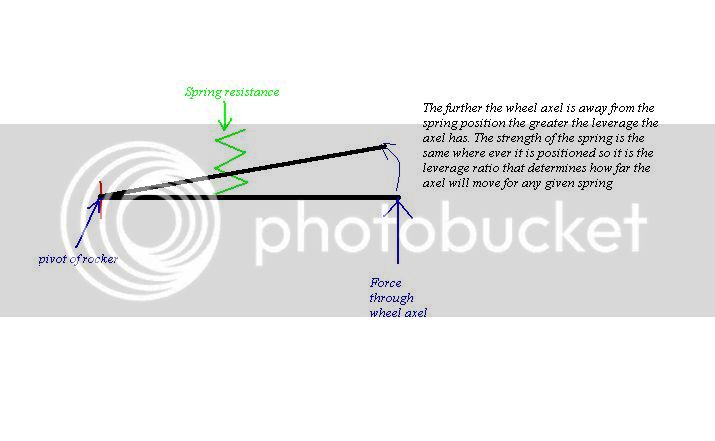

An alternative to treating the springs would be to make an adapter plate that moves the spring legs attachment points closer to the pivot of the rocker (shown by the red cross below) thus increasing the rockers leverage ratio, this is the same effect as a softer spring: the closer the attachment point to the rocker pivot point the softer the suspension action will be, on thphoto I have marked the cross giving approximately half the leverage which would make the spring effectively half as strong as it is now. I nicked the photo below offf another member I think, sorry hope you don't mind but it is the best photo of a rat trap i could find. The advantage of this is that you can convert back to standard or if you make an eccentric mount for the spring arm attachment it can be fine tuned to your taste.

An alternative to treating the springs would be to make an adapter plate that moves the spring legs attachment points closer to the pivot of the rocker (shown by the red cross below) thus increasing the rockers leverage ratio, this is the same effect as a softer spring: the closer the attachment point to the rocker pivot point the softer the suspension action will be, on thphoto I have marked the cross giving approximately half the leverage which would make the spring effectively half as strong as it is now. I nicked the photo below offf another member I think, sorry hope you don't mind but it is the best photo of a rat trap i could find. The advantage of this is that you can convert back to standard or if you make an eccentric mount for the spring arm attachment it can be fine tuned to your taste.

I like this idea better because i don't know how easy the spring would be to get off. I'm a little confused though. Wouldn't making the lever shorter increase the amount of force needed to compress the spring. I feel i would have to put the spring arms farther away from the wheel in order to decrease the amount of force needed to compress the spring. Does this make sense?

No you would need to move the spring inwards or the axel outwards, it is just leverage. You either increase the distance the wheel moves for a given spring movement or soften the spring. the only way to do the former is to move the spring in towards the rocker pivot.