The Renaissance Man

__CERTIFIED DIVER__ (Open Water & Open Dumpster)

Staff member

Moderator

Pro Member

Now that everyone and their brother has purchased a Nexus 7 recently (except me sense I already had a used one), a lot of us are faced with the problem of forcing it into a frame that was not designed to accept it. We probably all know about using 2x4's to pry open the rear stays and other equally barbaric methods. Today I discovered an easy CONTROLLED method for this. If you own a hand screw wood clamp or have a friend with one, it's a piece of cake.

Just slide the clamp between the drop outs and screw them apart. Of course (as with other methods) you must go past where you intend to finish so as to allow for the metal to spring back a little. The good thing is that you're applying equal pressure to both sides with very little effort and you're not going to scar up your paint if that's a concern.

I didn't feel the need for a before picture, but it was a normal width for a coaster hub.

Here's the clamp (these things have some real force):

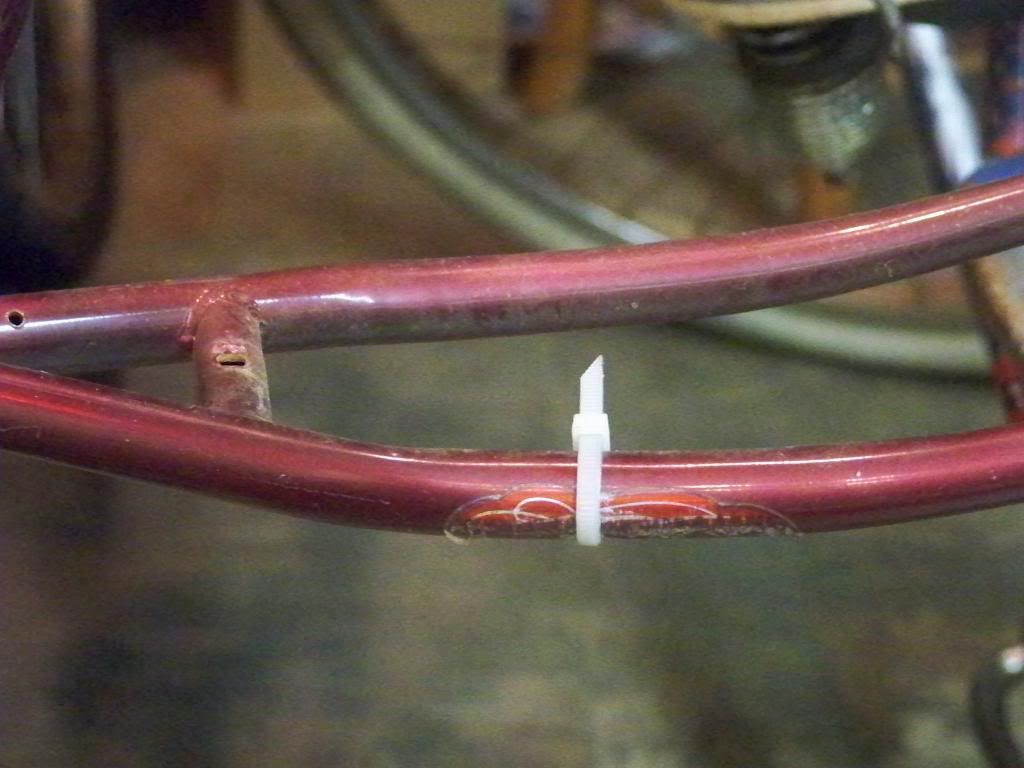

And here's the coaster hub back in place showing the added 1/2" or so on each side:

If you over shoot it, you can open the clamp, put it on the outside, and squeeze it back.

Just slide the clamp between the drop outs and screw them apart. Of course (as with other methods) you must go past where you intend to finish so as to allow for the metal to spring back a little. The good thing is that you're applying equal pressure to both sides with very little effort and you're not going to scar up your paint if that's a concern.

I didn't feel the need for a before picture, but it was a normal width for a coaster hub.

Here's the clamp (these things have some real force):

And here's the coaster hub back in place showing the added 1/2" or so on each side:

If you over shoot it, you can open the clamp, put it on the outside, and squeeze it back.