- Joined

- Oct 29, 2011

- Messages

- 135

- Reaction score

- 48

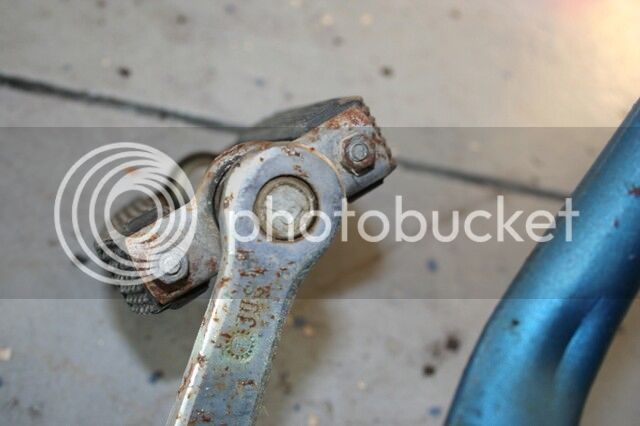

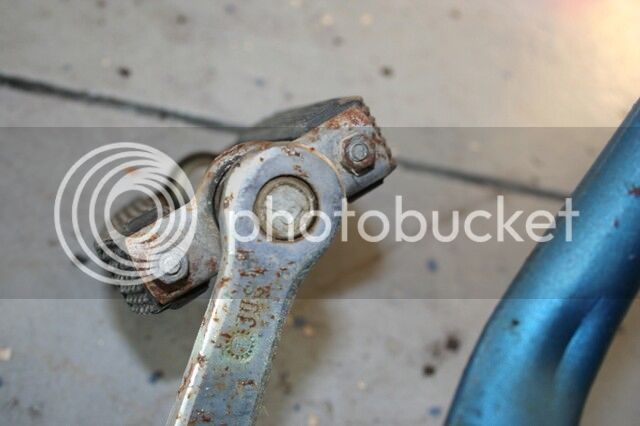

Hiya! This is off my Purple Nurple project. I am brand new to tearing down and building bikes and this is my first. I have a build thread, but I've hit a road block. I'm betting it's super easy and I'm just dumb, but how do I remove this crank (and pedals)? It's an early to mid 60's Royce Union. I'm planning on powder coating the frame and crank.

Thank you for any advice or instructions!

Thank you for any advice or instructions!