Did this with an Enwell headlight I found on ebay and a 9led flashlight (from CARQUEST). These flashlights pull apart easily with an o-ring (dental-type) pick. I used the existing switch on the headlight.

Here is the LED pack. The outermost ring is the negative, the inner ring and center are the positive. I left the spring in place to guide the wires out nicely.

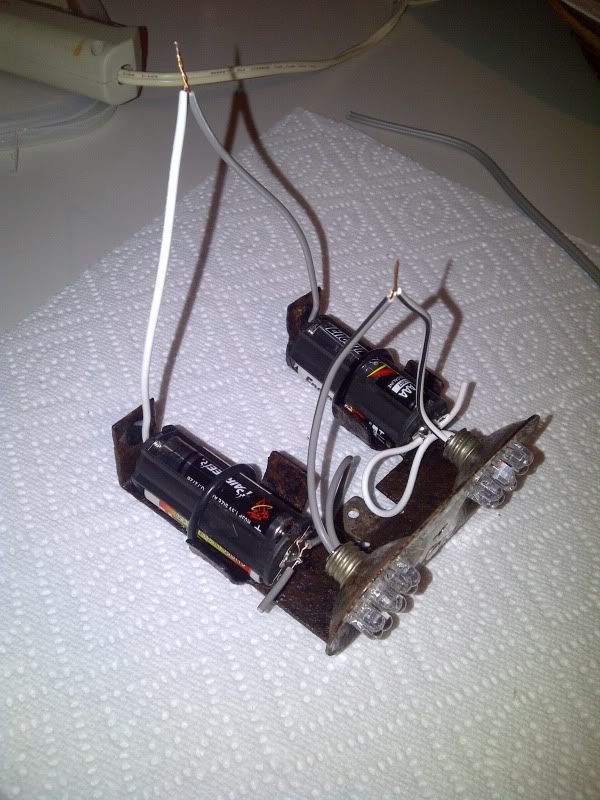

Thread a positive and negative wire down the center of the spring, I had wire, but lightweight speaker wire would work nicely. Solder one end of the negative wire to any one of the outer points and the other to the negative side of the battery pack. Solder the positive wire to the center where the spring attaches. and the other the outlet side of the switch. I snipped the inlet wire where it used to come in from the generator, then solder that to the positive side of the battery pack. I added another LED bulb for a low beam by simply soldering a negative lead from it to the battery pack, there is a contact point on the switch for this bulb position on this light already.

I glued the LED pack to the lens with clear silicone. I will use hot glue next time for a cleaner look and quicker setup, learn from my mistakes. lol

You can also see how I made a simple mount to my springer with some cable clamps, 1/4-20 threaded rod, and some wingnuts, The threaded spikes are available from studsandspikes.com and I like the look with this bike.

High beam...more than just show, you can see quite a way down the road with this baby!

Low beam

I'm by no means an electrical whiz, and this project took less than a half hour. Pretty basic soldering, and the more you do it, the better you get. Hope this helps!

i just want to switch this to and LED... i want a switch on there as well i know i have to buy a battery pack and an LED flashlight that i will take apart and connect to the battery pack ive never soldered or did electrical stuff please help!

i just want to switch this to and LED... i want a switch on there as well i know i have to buy a battery pack and an LED flashlight that i will take apart and connect to the battery pack ive never soldered or did electrical stuff please help!