You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

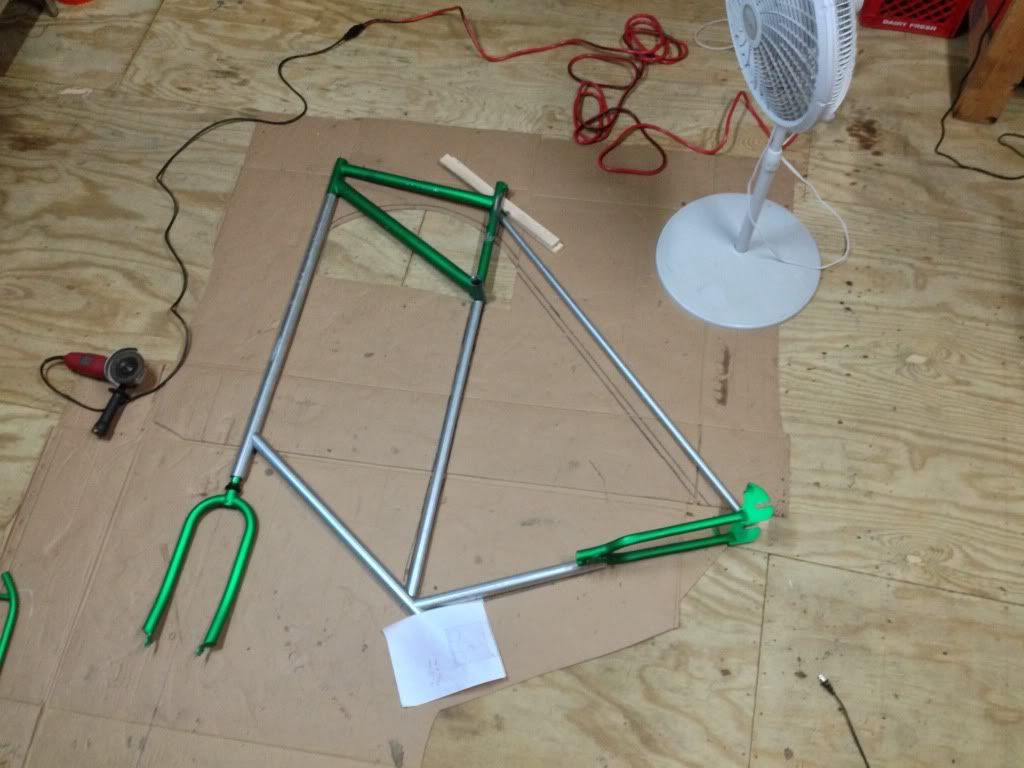

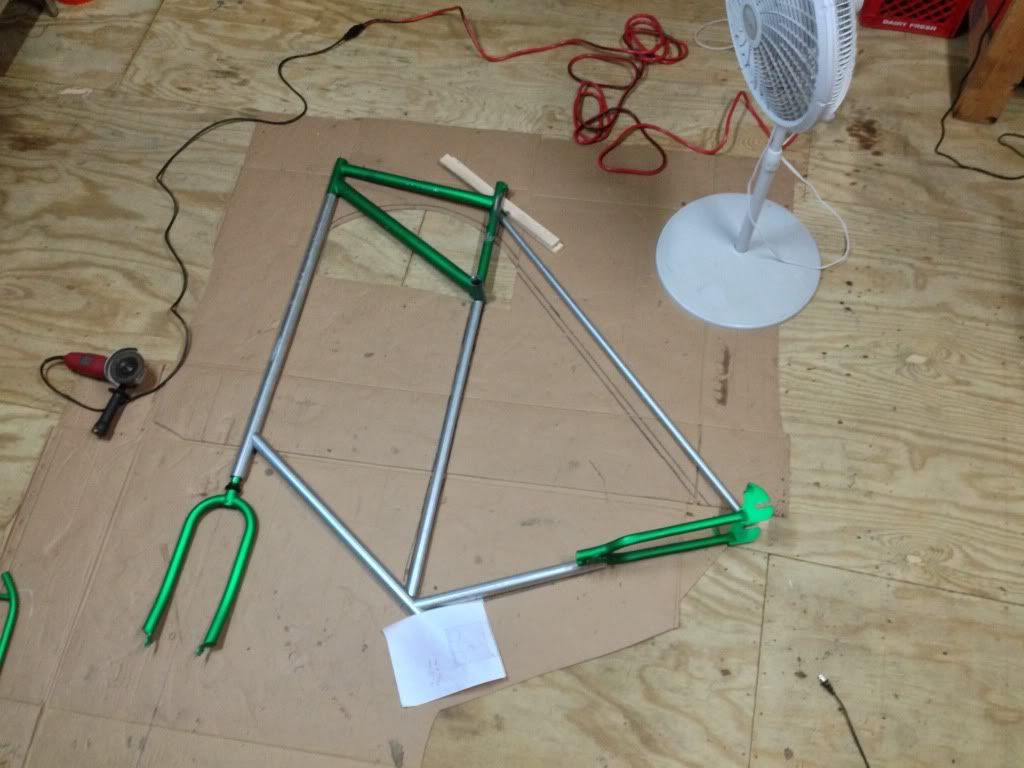

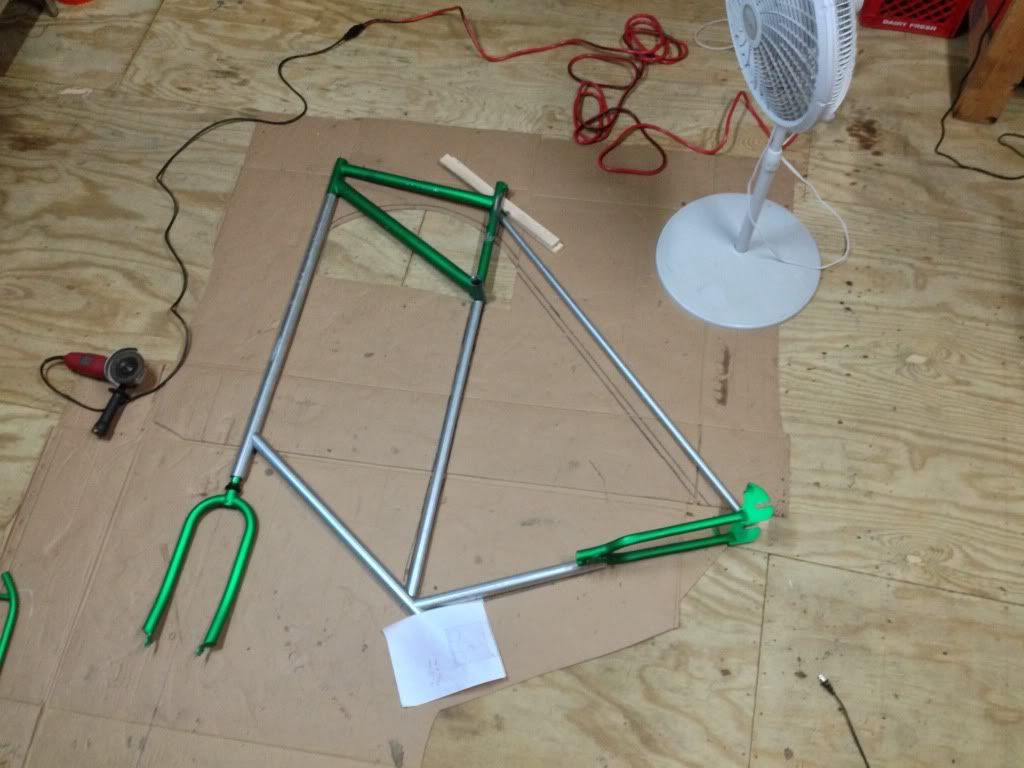

Mongoose Beast Fat Bike build and ideas

- Thread starter yoothgeye

- Start date

Help Support Rat Rod Bikes Bicycle Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

10"x1 1/8" threadless, Beast is 7 1/4"x1" threaded. Might work with the right bearing race, but it's not a simple bolt-on. :|jwood said:No comments on the surley forks??

Just measured the forks on the beast and they are 1 1/8" x 7 1/4" threaded.deorman said:10"x1 1/8" threadless, Beast is 7 1/4"x1" threaded. Might work with the right bearing race, but it's not a simple bolt-on. :|jwood said:No comments on the surley forks??

yoothgeye

I build stuff.

Cost of that fork is more than half what I paid for the bike.

You get to a point where you are putting makeup on a pig... expensive makeup, be careful.

If you upgrade the hubs, the brakes, the tubes, the tires, the spokes, the fork, the stem, cranks, the handlebar, the seatpost, the saddle, add new brakes, etc... eventually you've got a lot of really nice parts on a very cheap frame and you're wondering why you didn't just save all the money you spent in parts to buy a nicer starter bike or a used/built fat bike.

To each their own. I bought my Beast to get into the fat game cheap... and it worked, I'm done with my mods, total investment after purchase: $0. Well, that's not fair, since I bought some of those parts once upon a time, so it's more like $30.

I need to get a current picture of mine, I'm taking it on vacation with us next week.

You get to a point where you are putting makeup on a pig... expensive makeup, be careful.

If you upgrade the hubs, the brakes, the tubes, the tires, the spokes, the fork, the stem, cranks, the handlebar, the seatpost, the saddle, add new brakes, etc... eventually you've got a lot of really nice parts on a very cheap frame and you're wondering why you didn't just save all the money you spent in parts to buy a nicer starter bike or a used/built fat bike.

To each their own. I bought my Beast to get into the fat game cheap... and it worked, I'm done with my mods, total investment after purchase: $0. Well, that's not fair, since I bought some of those parts once upon a time, so it's more like $30.

I need to get a current picture of mine, I'm taking it on vacation with us next week.

You could also weld a disc brake mount on the original forks.deorman said:Well that makes it easier. 8)

a thrashed fixer-upper fatbike would still be over $1000. and it would have a 10-sp rear der, cogs, and shifter, so when you had to replace ANYTHING it would cost more than any series of upgrades I have seen anyone do.

Just put together my new beast and after close inspection I was amazed at what I found. Both front and rear rims appear to be splitting apart. Picture a long flat piece of steel rolled in a circle and the butted ends welded together. That's where they're separating. I always assumed rims were spun so theyre seamless. Are these rims now useless??

I haven't taken a magnet to them so I don't know if they're steel or aluminum. If steel I may be able to dismount the tire and stitch weld them from inside. I'll need to find someone to weld them if they're aluminum. Sucks! I guess when you pay for cheap Chinese crap, you get exactly that!

How are your wheels holding up?

I haven't taken a magnet to them so I don't know if they're steel or aluminum. If steel I may be able to dismount the tire and stitch weld them from inside. I'll need to find someone to weld them if they're aluminum. Sucks! I guess when you pay for cheap Chinese crap, you get exactly that!

How are your wheels holding up?

I recently received my beast and after close inspection it seems I have lucked out and haven't had any issues that others have run into with the Beast. My rims are fine so far. Now the weld seam is very apparent but is holding strong. It's to my understanding that the rims on this thing are aluminum.

All metal rims are made from straight material, curved and joined up. Some are welded at the joint. Generally aluminum rims are pinned together. The pins are press fit. The pins look like a nail with both ends cut off. Most aluminum rims are drawn (extruded thru a die) and have hollow cross sections, including those where the pins go. Most steel rims are folded over sheet metal, seam welded where the sides meet up and welded at the joint.

Once built up in a wheel, the spoke tension pulls the two ends towards each other. Radially spoked wheels pull laterally across the joint the least, 3x or 4x will pull more.

High end rims get the brake surface machined so you don't feel the brake pad hitting the joint.

The only seamless rims are molded from various plastics (thermo plastic, fibreglass, abs, etc) or carbon fiber.

Wood rims are made from straight boards, steamed, bent, glued and clamped to a circular form. Once dried, they are turned on a lathe to fine tune the final shape.

Could be the pins got broke. Rare, very rare. The best fix for that is to unspoke the wheel, pull the joint apart and put in new pins.

I have seen failed rims where the aluminum cracked where the pins are pressed in. Also very rare. More often from crash damage where the rims were severely bent at the joint.

How big is the gap? Could you slide a business card in the gap? Credit card? Do the sides line up? Can you catch a finger nail on them?

Rims do flex a small amount with every rotation, more under a heavier load. Welding aluminum without proper heat treating afterwards will leave the joint brittle and it will fail rather quickly.

Because these bikes weren't built for rim caliper brake use, the joint doesn't need to be all that perfect. Or even close.

There are plenty of better quality rims available from the fat bike market. They will cost a bit but will still be made in China like many other bike parts.

If it's that bad and you bought the bike less than 30 days ago, take it back and get a refund, order another. that's the company line for defective product.

Rick

Once built up in a wheel, the spoke tension pulls the two ends towards each other. Radially spoked wheels pull laterally across the joint the least, 3x or 4x will pull more.

High end rims get the brake surface machined so you don't feel the brake pad hitting the joint.

The only seamless rims are molded from various plastics (thermo plastic, fibreglass, abs, etc) or carbon fiber.

Wood rims are made from straight boards, steamed, bent, glued and clamped to a circular form. Once dried, they are turned on a lathe to fine tune the final shape.

Could be the pins got broke. Rare, very rare. The best fix for that is to unspoke the wheel, pull the joint apart and put in new pins.

I have seen failed rims where the aluminum cracked where the pins are pressed in. Also very rare. More often from crash damage where the rims were severely bent at the joint.

How big is the gap? Could you slide a business card in the gap? Credit card? Do the sides line up? Can you catch a finger nail on them?

Rims do flex a small amount with every rotation, more under a heavier load. Welding aluminum without proper heat treating afterwards will leave the joint brittle and it will fail rather quickly.

Because these bikes weren't built for rim caliper brake use, the joint doesn't need to be all that perfect. Or even close.

There are plenty of better quality rims available from the fat bike market. They will cost a bit but will still be made in China like many other bike parts.

If it's that bad and you bought the bike less than 30 days ago, take it back and get a refund, order another. that's the company line for defective product.

Rick

Thanks for the explanation Rick!

I did some checking on my other bikes and it does seem that all of my other wheels have the same "seam" albeit much less noticeable. I think its the fact that these wheels are so wide that it's much easier to see the seams. The sides are pretty tight with no visible gaps, I can feel it with my nail but they're closed. It's the top that seems to be either pulling away or separating. And it really only one side that's popping up on both wheels. However I tried to pull on the rim a bit and it doesn't seem to be opening up. The separations are fairly noticeable but you still can't fit a business card, or anything even thinner in them. After reading you explanation I'm thinking the wheels are fine. Maybe there was some slop in the pins holders and when the spokes were tightened it pulled the gaps uneven. I'll inspect the gaps after some road time to see if they show signs of pulling away.

I did some checking on my other bikes and it does seem that all of my other wheels have the same "seam" albeit much less noticeable. I think its the fact that these wheels are so wide that it's much easier to see the seams. The sides are pretty tight with no visible gaps, I can feel it with my nail but they're closed. It's the top that seems to be either pulling away or separating. And it really only one side that's popping up on both wheels. However I tried to pull on the rim a bit and it doesn't seem to be opening up. The separations are fairly noticeable but you still can't fit a business card, or anything even thinner in them. After reading you explanation I'm thinking the wheels are fine. Maybe there was some slop in the pins holders and when the spokes were tightened it pulled the gaps uneven. I'll inspect the gaps after some road time to see if they show signs of pulling away.

If you can post a picture it might help us in seeing what you are trying to tell via words.dubless said:Thanks for the explanation Rick!

I did some checking on my other bikes and it does seem that all of my other wheels have the same "seam" albeit much less noticeable. I think its the fact that these wheels are so wide that it's much easier to see the seams. The sides are pretty tight with no visible gaps, I can feel it with my nail but they're closed. It's the top that seems to be either pulling away or separating. And it really only one side that's popping up on both wheels. However I tried to pull on the rim a bit and it doesn't seem to be opening up. The separations are fairly noticeable but you still can't fit a business card, or anything even thinner in them. After reading you explanation I'm thinking the wheels are fine. Maybe there was some slop in the pins holders and when the spokes were tightened it pulled the gaps uneven. I'll inspect the gaps after some road time to see if they show signs of pulling away.

If you have not seen it yet you might want to check out "Tattoos by Albert's" build thread: viewtopic.php?f=74&t=74627

Hint:

Luke.

Hint:

Luke.

dracothered said:If you can post a picture it might help us in seeing what you are trying to tell via words.dubless said:Thanks for the explanation Rick!

Here are a few pics of what I'm talking about.

I think because of the width of these wheels it makes it look worse than it is. But then again I'm not sure if this looks terrible or not.

Aside from a few Arayas and Weinmanns that I've had over the years, most of my bikes develop some degree of deformity in the rear rims, often at the seams. As a result I end up keeping them laced pretty tight. I noticed a similar degree of visibility on my Beast's rear wheel seam when I went to re-tension/true it after putting a few miles, curbs, and branches under it. Doesn't seem to be actually coming apart so far :? , I suppose only time will tell. :|

I think you are ok there, it just looks worse than I think it really is.dubless said:dracothered said:If you can post a picture it might help us in seeing what you are trying to tell via words.dubless said:Thanks for the explanation Rick!

Here are a few pics of what I'm talking about.

I think because of the width of these wheels it makes it look worse than it is. But then again I'm not sure if this looks terrible or not.

Yeah I might've over reacted a bit since my other non-fattie bike wheels look nothing like that.

However, I went to Target at lunch today and took a closer look at some of the bikes especially the cruisers.

Most of them have some form of wheel deformity at the seam so I guess it's pretty normal. Just looks a bit weird I guess.

I'll watch it closely over the next few weeks as I ride it to see if the separation grows. If it does I'll break the wheels down and probably re-pin them.

However, I went to Target at lunch today and took a closer look at some of the bikes especially the cruisers.

Most of them have some form of wheel deformity at the seam so I guess it's pretty normal. Just looks a bit weird I guess.

I'll watch it closely over the next few weeks as I ride it to see if the separation grows. If it does I'll break the wheels down and probably re-pin them.

Most pinned aluminum rims are pined at the edges. I'd be surprised if they used more than the usual 2 pins on the Beast rims. Because these rims are so wide, they look to be warping across wise. I plan on unspoking a Beast pair for repainting this summer. I wonder if I could get them xray'ed to see how many pins there are. maybe just holding them up to a bright light will work at the joint.

Here is a link to a photo that shows a typical cross section. The two small round holes is where the pins go at the joint.

http://www.global-b2b-network.com/b2b/9 ... _rims.html

rick

Here is a link to a photo that shows a typical cross section. The two small round holes is where the pins go at the joint.

http://www.global-b2b-network.com/b2b/9 ... _rims.html

rick

LukeTheJoker said:If you have not seen it yet you might want to check out "Tattoos by Albert's" build thread: viewtopic.php?f=74&t=74627

Hint:

Luke.

You are going to need quite a ladder for that!

rickpaulos said:Most pinned aluminum rims are pined at the edges. I'd be surprised if they used more than the usual 2 pins on the Beast rims. Because these rims are so wide, they look to be warping across wise. I plan on unspoking a Beast pair for repainting this summer. I wonder if I could get them xray'ed to see how many pins there are. maybe just holding them up to a bright light will work at the joint.

Here is a link to a photo that shows a typical cross section. The two small round holes is where the pins go at the joint.

http://www.global-b2b-network.com/b2b/9 ... _rims.html

rick

Thanks for that pic! It's beginning to make more sense now. Because of the width of these wheels they're probably more prone to warping in the centers. Especially if pins are used only on the edges, where mine are actually pretty tight.

I guess I'll just need to watch em closely and pay attention to spoke tightness and true. Great info what an awesome forum!!

Now onto more Beastie goodness!!