I picked up a Stingray Chopper from a Wifes relative for $5 and we are going to do a little customizing project out of it. Nothing too wild but just make it a little different. Not really knowing which way its going or where it will end up. Paint is a definite. Hoping to get my hands on the Alsa Corp. Killer Cans Candy Orange for the frame. I love all they have in rattle cans. http://www.alsacorp.com/killercans.htm

I thought about doing all the spokes but looking at the photos again, I am wondering how it would look with a 26" or maybe a 28" wheel in front instead of the 24". Will probably get the OCC V handle bar for it. I like the look. I also want to make the rear fender wrap further around. Maybe get a second fender then cut and tig them together. Headlight and taillight. Plans are fluid and will flow as it goes. Slowly going to bring it back to life for my Wife to fool around on. It will probably get passed on to my daughter after that, when she is older. A fun family project.

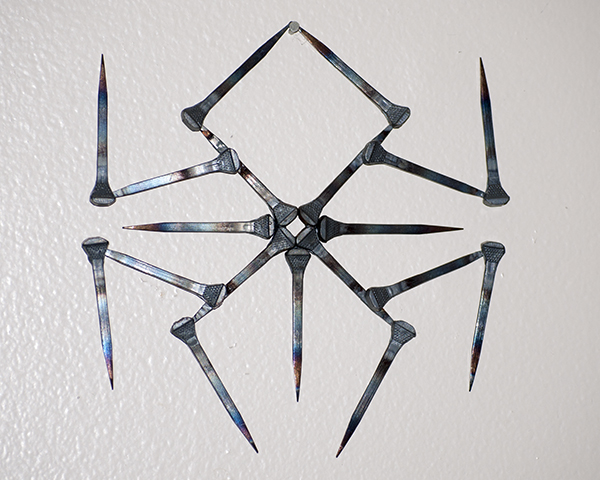

Anyways... here are the "Before" shots:

I thought about doing all the spokes but looking at the photos again, I am wondering how it would look with a 26" or maybe a 28" wheel in front instead of the 24". Will probably get the OCC V handle bar for it. I like the look. I also want to make the rear fender wrap further around. Maybe get a second fender then cut and tig them together. Headlight and taillight. Plans are fluid and will flow as it goes. Slowly going to bring it back to life for my Wife to fool around on. It will probably get passed on to my daughter after that, when she is older. A fun family project.

Anyways... here are the "Before" shots: