You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

NonGoose 26 BMX project

- Thread starter rev106

- Start date

Help Support Rat Rod Bikes Bicycle Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

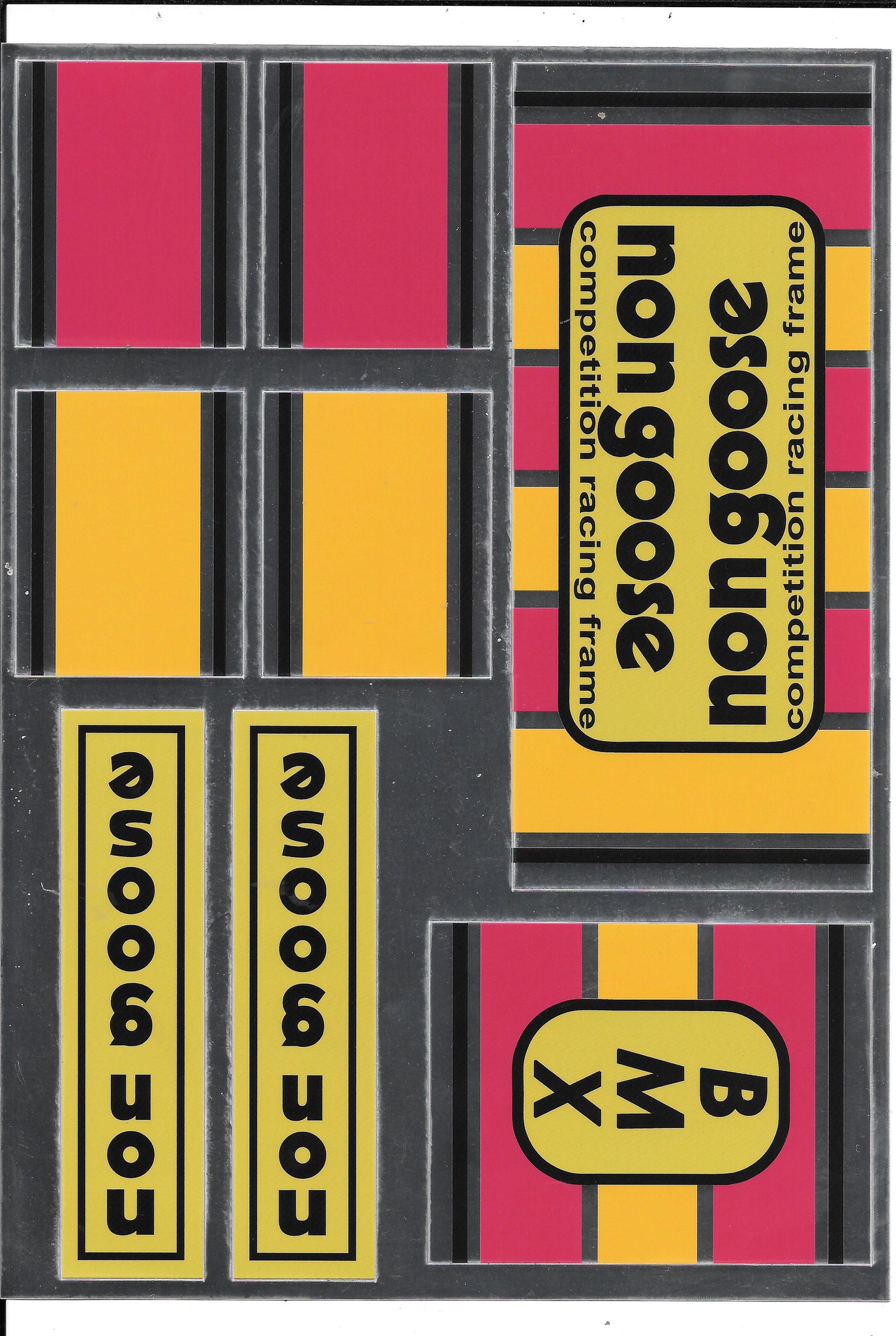

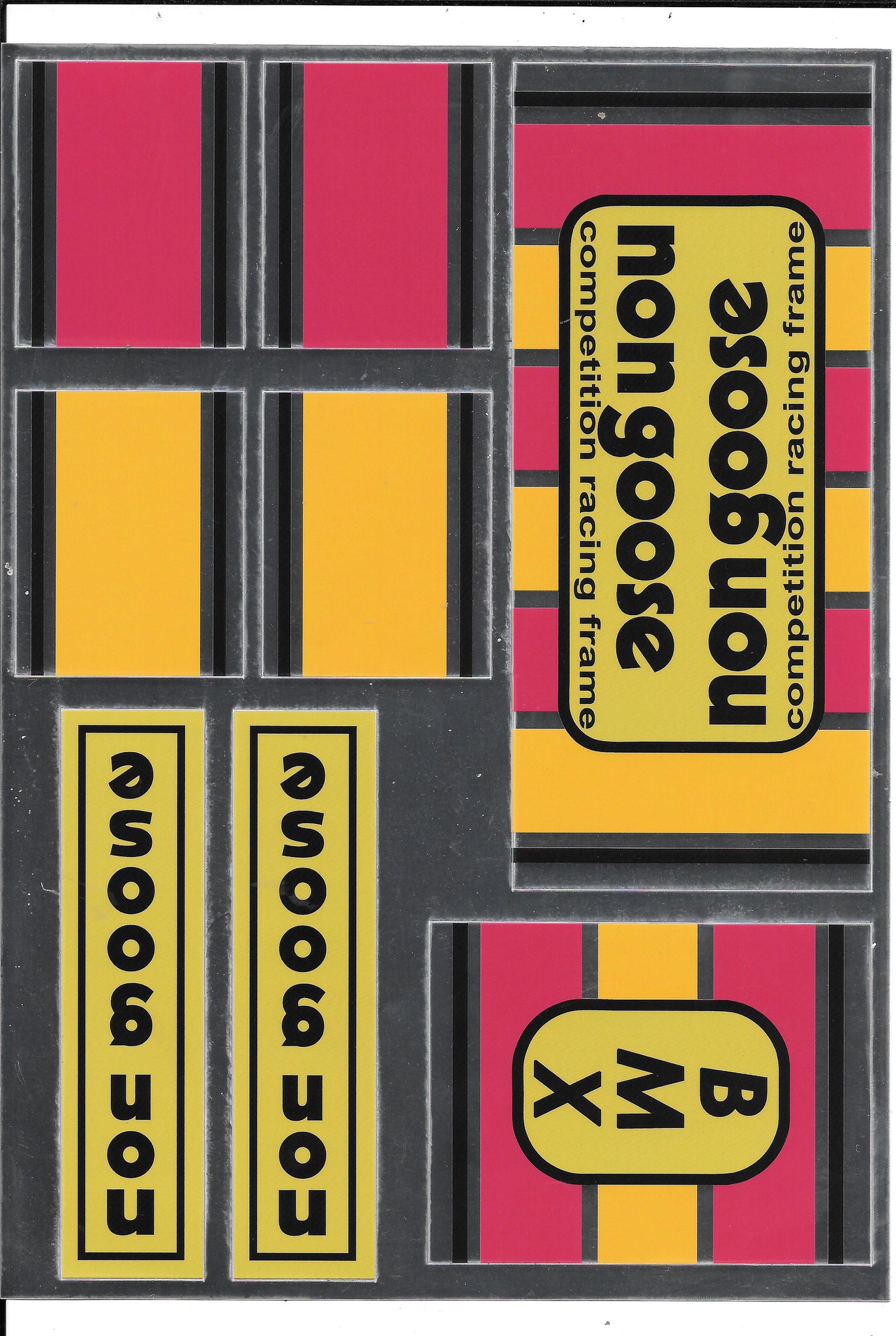

look closely.. Got the stickers done.

stickers01 by Paul de Valera, on Flickr

stickers01 by Paul de Valera, on Flickr

stickers02 by Paul de Valera, on Flickr

stickers02 by Paul de Valera, on Flickr

stickers01 by Paul de Valera, on Flickr

stickers01 by Paul de Valera, on Flickr stickers02 by Paul de Valera, on Flickr

stickers02 by Paul de Valera, on FlickrMaybe a, 'by RevCo', line under the Mfg in U.S.A. on the Chrome Moly sticker?

Chatworthy instead of Chatsworth?

Looks great!

Jason

Chatworthy instead of Chatsworth?

Looks great!

Jason

well yeah, that would have been cool but we already made them.  I'll post pics when I have them on the bike and as others materialize if I can get pictures of them I'll post them up here. I have seen one other Yellow built up and an orange one, blue one x2, and one being nickel plated is in the mix....

I'll post pics when I have them on the bike and as others materialize if I can get pictures of them I'll post them up here. I have seen one other Yellow built up and an orange one, blue one x2, and one being nickel plated is in the mix....

$29.95

Crossroads Home Décor A Biker's Prayer, Gift for Motorcycle Riders, Inspirational Bike Picture Frame, 6451BW

Crossroads_Home_Decor

$19.99

Electra Glide Wall Decal 2ft Long Sport Harley Davidson Bike Motorcylce Sticker Man Cave Garage Boys Room Decor

FatCat Wall Graphics

$19.99

Old River Outdoors Bicycle/Motorcycle Chain Picture Frame 4" X 6" Photo - Faux Bike Chain

Old River Outdoors (USA Merchant)

That paint is sweet!

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

- Joined

- Jun 3, 2018

- Messages

- 61

- Reaction score

- 42

In general the tri moly frames has so so welding on them, whereas the full cr-mo frames had much better welding.

Your work is awesome!!

The problem with the Moto Mag frame and many early BMX specific frames were that they were designed to be used with 46/18 tooth gearing and shorter 167/170mm crank arms, and much larger diameter rear gear that would keep the chain away from the chain stay. but in time when the flip flop hub became popular and our crank arms became longer (170mm to 175/180mm) our gearing went from 46/18 to 44/16 because of the longer crank arm with the theory at the time was to change the gearing to a more respectable size to counter act the longer stroke of the crank to enable the rider get the bike rolling. So when we would run race gearing with flip flop hubs 44/14 a smaller diameter rear gear made the chain come unbelievably close to the chain stay, and usually ended up rubbing through the chain stay over time, just from natural chain slap. Have you ever thought of doing side work repairing old BMX frames? We used to have the chain hole welded and re ground, a cheap fix but somewhat nasty looking. Changing the whole tube, I think you would do a awesome job. Just an idea to save older frames from the scrap yard. Very nice work and build!!

Your work is awesome!!

The problem with the Moto Mag frame and many early BMX specific frames were that they were designed to be used with 46/18 tooth gearing and shorter 167/170mm crank arms, and much larger diameter rear gear that would keep the chain away from the chain stay. but in time when the flip flop hub became popular and our crank arms became longer (170mm to 175/180mm) our gearing went from 46/18 to 44/16 because of the longer crank arm with the theory at the time was to change the gearing to a more respectable size to counter act the longer stroke of the crank to enable the rider get the bike rolling. So when we would run race gearing with flip flop hubs 44/14 a smaller diameter rear gear made the chain come unbelievably close to the chain stay, and usually ended up rubbing through the chain stay over time, just from natural chain slap. Have you ever thought of doing side work repairing old BMX frames? We used to have the chain hole welded and re ground, a cheap fix but somewhat nasty looking. Changing the whole tube, I think you would do a awesome job. Just an idea to save older frames from the scrap yard. Very nice work and build!!

I've done a fair amount off frame repair in the past and will keep doing so! If you look at my bike build off bike, the double trouble fire road cruiser you'll see that the making of these frames really helped me become a better welder!

carlos04 by Paul de Valera, on Flickr

carlos04 by Paul de Valera, on Flickrcarlos03 by Paul de Valera, on Flickrcarlos03 by Paul de Valera, on Flickr

carlos03 by Paul de Valera, on Flickr

carlos03 by Paul de Valera, on FlickrOh <blank> yeah!

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

carlos04 by Paul de Valera, on Flickr

carlos03 by Paul de Valera, on Flickrcarlos03 by Paul de Valera, on Flickr

carlos03 by Paul de Valera, on Flickr

Nice!

Sent from my iPhone using Tapatalk

non goose 26 bmx crusier by Paul de Valera, on Flickr

non goose 26 bmx crusier by Paul de Valera, on Flickr non goose 26 bmx crusier by Paul de Valera, on Flickr

non goose 26 bmx crusier by Paul de Valera, on Flickr non goose 26 bmx crusier by Paul de Valera, on Flickr

non goose 26 bmx crusier by Paul de Valera, on Flickr non goose 26 bmx crusier by Paul de Valera, on Flickr

non goose 26 bmx crusier by Paul de Valera, on Flickr ceaser02 by Paul de Valera, on Flickr

ceaser02 by Paul de Valera, on Flickr ceaser03 by Paul de Valera, on Flickr

ceaser03 by Paul de Valera, on Flickr thumbnail by Paul de Valera, on Flickr

thumbnail by Paul de Valera, on FlickrSweet. Any red ones pop up yet? That’s the color I’ll be going with on mine.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Man, how cool are these bikes? REAL cool son, reeeeeaaaaaal cool

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Outstanding!

Non goose

Non goose Non goose

Non goose