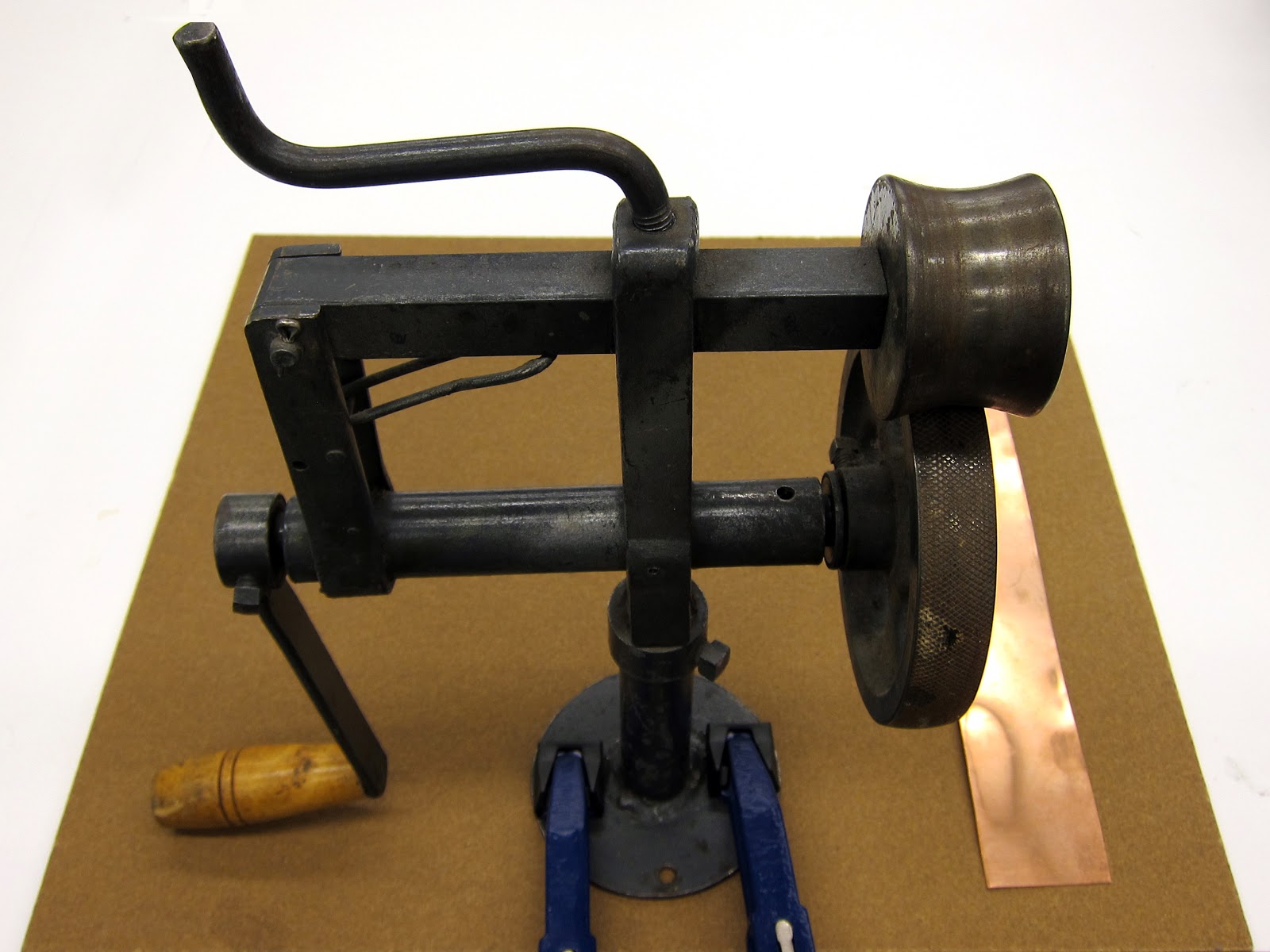

I don't own a fender roller, but I do happen to have a Harbor Freight English wheel I bought on sale when they were clearancing out the old design wheels. While I did have some success with it, I still think a fender roller is the way to go for smaller damage.

Initially I thought using my rubber tire upper wheel would be the way to go, but the fender had too much damage and I couldn't get it do reshape more than the basic shape using the smallest radius lower anvil and the rubber tire top wheel. So, I figured the fender was junk anyhow and I swapped for the flat upper wheel in steel.

What I wasn't sure about was just how much pressure to use to flatten out the dents. Eventually I just kept cranking the bottom adjuster until the fender got smooth, but there was another problem now that the fender metal was all smooth. I tried wheeling along the length of the fender, side to side, and diagonally but all resulted in the fender flattening out from side to side, and curving in from the ends, with a result that I had a wide fender more suited for a 12 inch wheel instead of the 26 it was made for.

I had seen this result before so I knew what to do... Bike fenders are pretty flimsy so all I had to do was grab both ends and pull them apart...as the ends get farther away from each other the sides of the fender move back to where you want them. Most of the the rest of the shaping was done by squeezing the sides of the fender together by hand, using my thumbs to make the bend more in the sides than the center of the fender. I used a pair of large end nipper pliers to add some more curve to the sides. If I had a suitable dolly some mallet and dolly work would have done a bit better work on the edge...

While the end result is not what I'd call show quality work, it did save a totally junk fender.. I was out of time to spend on iit but probably spent less than an hour working on it. More time and care and I think I could have made it paint ready.

No clue what the fender was from.. had a small Gulco reflector on it and two straight braces....

Any suggestions for improving my technique? I still want to build a roller with a large diameter convex wheel and a small diameter concave wheel, which I think is the cure for the total reshaping problem.

Pictures to follow.

Initially I thought using my rubber tire upper wheel would be the way to go, but the fender had too much damage and I couldn't get it do reshape more than the basic shape using the smallest radius lower anvil and the rubber tire top wheel. So, I figured the fender was junk anyhow and I swapped for the flat upper wheel in steel.

What I wasn't sure about was just how much pressure to use to flatten out the dents. Eventually I just kept cranking the bottom adjuster until the fender got smooth, but there was another problem now that the fender metal was all smooth. I tried wheeling along the length of the fender, side to side, and diagonally but all resulted in the fender flattening out from side to side, and curving in from the ends, with a result that I had a wide fender more suited for a 12 inch wheel instead of the 26 it was made for.

I had seen this result before so I knew what to do... Bike fenders are pretty flimsy so all I had to do was grab both ends and pull them apart...as the ends get farther away from each other the sides of the fender move back to where you want them. Most of the the rest of the shaping was done by squeezing the sides of the fender together by hand, using my thumbs to make the bend more in the sides than the center of the fender. I used a pair of large end nipper pliers to add some more curve to the sides. If I had a suitable dolly some mallet and dolly work would have done a bit better work on the edge...

While the end result is not what I'd call show quality work, it did save a totally junk fender.. I was out of time to spend on iit but probably spent less than an hour working on it. More time and care and I think I could have made it paint ready.

No clue what the fender was from.. had a small Gulco reflector on it and two straight braces....

Any suggestions for improving my technique? I still want to build a roller with a large diameter convex wheel and a small diameter concave wheel, which I think is the cure for the total reshaping problem.

Pictures to follow.