You know maybe it is gonna be one of those "Just Plain Defective" ones!I'm sure you've already looked into this, but is are your cones adjusted properly? If the hub doesn't spin freely, an easier gear ratio just means you'll be going as slowly as before, only with a little less effort.

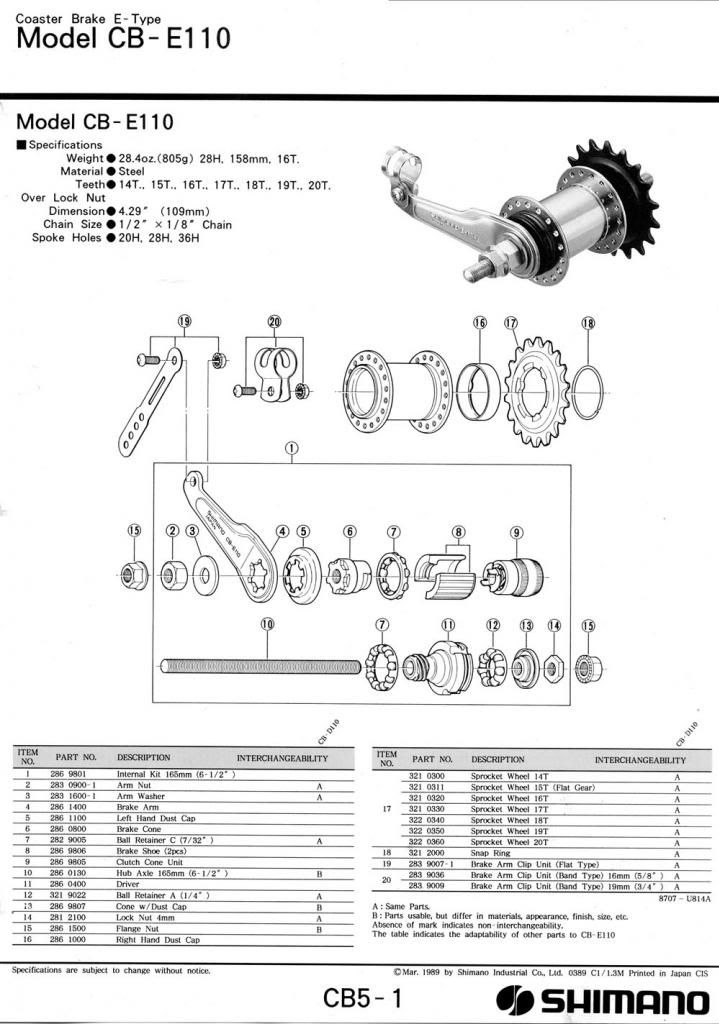

I've heard of some hubs having a "breaking in" period, but I haven't observed it yet myself. All of the CB hubs I've used (and I've used probably an equal number of vintage and modern, Chinese hubs) either worked great from the start, or worked great after being overhauled. I only have one that has been bad from the start, and seemingly isn't going to "break in" with time (it's one of those Shimano CB-E110; I suspect the problem is the clutch spring, which I thought may have just been stiff initially, but I now think is just plain defective).

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Coaster brake questions

- Thread starter mornview

- Start date

Help Support Rat Rod Bikes Bicycle Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Falcon is still in operation; not sure if they still make C/B hubs... they do make some very cheeeeep yet functional friction shifters. They had a website a few years back, but I just googled it for a minute, and I guess it's gone? Anyway, I think that Falcon and KT are separate entities, but you're right: both the HiStop hubs and the Falcon cb hubs I've seen were straight-up shimano clones, with a few apparent differences, most likely born out of a desire to save money.

Horsefarmer, it may be that you're dealing with a higher gear ratio, or it may be that your cones are tight. How well does the wheel spin in the stand? There's always going to be some drag with a coaster hub, and most hubs have considerably more drag than a Komet (due to how the Komet's design keeps the brakes from dragging while coasting).... You can't really over-grease a Falcon or similar CB hub with too much grease, but excessive grease does add friction, so there may be a TINY decrease in efficiency, so i suspect your issues are caused by something else (eg, hub is too tight, something is dragging inside the hub, or maybe you do just need a lower gear...)

Horsefarmer, it may be that you're dealing with a higher gear ratio, or it may be that your cones are tight. How well does the wheel spin in the stand? There's always going to be some drag with a coaster hub, and most hubs have considerably more drag than a Komet (due to how the Komet's design keeps the brakes from dragging while coasting).... You can't really over-grease a Falcon or similar CB hub with too much grease, but excessive grease does add friction, so there may be a TINY decrease in efficiency, so i suspect your issues are caused by something else (eg, hub is too tight, something is dragging inside the hub, or maybe you do just need a lower gear...)

You know maybe it is gonna be one of those "Just Plain Defective" ones!

Could explain the low miles..... who wants to put a lot of miles in on a defective hub, right?

In what sense does it not work? The hub doesn't spin freely, the brake doesn't stop, etc.? In most cases I'm just guessing the grease has hardened up from sitting idle for 25 years. I'm sure overhauling it with some fresh new grease would do wonders (then again, I overhaul the moving parts of any old bike I buy, regardless of how good or bad it's working, but that might just be the OCD in me).

Everything works. But the Brake does not stop at all. Sometimes it works very slowly

Well, on my 56 Hawthorne with a new departure coaster brake, it did like you say "no brakes" after maybe like 6 turns backwards "brakes"!Everything works. But the Brake does not stop at all. Sometimes it works very slowly

Turns out it was the transfer spring was broken - got a replacement and all is well.

Probably just about every bike we get our hands on - except the near perfect ones, had a "problem" that led to them not being ridden anymore. Sometimes obvious things like broken frames, sometimes little things like broken spring in the hub and "no brakes"!

$24.99

Top Brass Bicycle/Motorcycle Chain Picture Frame 5" X 7" Photo - Faux Bike Chain

Old River Outdoors (USA Merchant)

$19.99

Old River Outdoors Bicycle/Motorcycle Chain Picture Frame 4" X 6" Photo - Faux Bike Chain

Old River Outdoors (USA Merchant)

$34.99

Bicycle/Motorcycle Chain Picture Frame 8" X 10" Photo - Faux Bike Chain Vertical or Horizontal Table Top Display

Old River Outdoors (USA Merchant)

$19.99

Electra Glide Wall Decal 2ft Long Sport Harley Davidson Bike Motorcylce Sticker Man Cave Garage Boys Room Decor

FatCat Wall Graphics

Just wanted to add my 2 cents. I recently bought a set of 3G wheels with the KT 2 speed kickback. I originally had my concerns, but after having ridden it a bunch I must say I couldn't be happier. The hub works flawlessly and the brakes are the best I've had on a coaster brake bike.

& those wheels look so good on that bike, too!Just wanted to add my 2 cents. I recently bought a set of 3G wheels with the KT 2 speed kickback. I originally had my concerns, but after having ridden it a bunch I must say I couldn't be happier. The hub works flawlessly and the brakes are the best I've had on a coaster brake bike.

Just wanted to add my 2 cents. I recently bought a set of 3G wheels with the KT 2 speed kickback. I originally had my concerns, but after having ridden it a bunch I must say I couldn't be happier. The hub works flawlessly and the brakes are the best I've had on a coaster brake bike.

I *REALLY* wish there was some way to buy those hubs seperately. I've wanted a kickback hub for a minute now, and combine that with my love of my KT's single speed hubs, and you've got a hub I really want.

I just got an Email from another guy, He says he sprays WD 40 in any crack he can find on them and that softens up the grease and they work then. Anyone done that?

Just to see if it works. WD-40is not viscous enough for lube needs of ball bearings.I just got an Email from another guy, He says he sprays WD 40 in any crack he can find on them and that softens up the grease and they work then. Anyone done that?

PErsonally, I've never touched a coaster with wd-40, although I guess I would if some of the hardware were locked up-- a bit of penetrating oil to free up a recalcitrant jam-nut makes sense. But, a repack ain't nothing but a 5 minute job, so I would take the time to do that proper...

Not an expert, but I understand grease is oil mixed with soap or other additives. Over time the grease breaks down the oil oxidizes or evaporates or leaks away, leaving behind dry soap, dirt, and metal particles.

Makes sense to me to disassemble, clean and then regrease.

Makes sense to me to disassemble, clean and then regrease.

Hey isn't soap made out of Horse Hooves. or Pig Fat boiled? Or was that just on the Beverly Hillbilly show.

How easy is it to take one apart and adjust it properly? It would be a great helpful thread as to what to take apart and how to put together properly again.

How easy is it to take one apart and adjust it properly? It would be a great helpful thread as to what to take apart and how to put together properly again.

Most coaster brakes are easily dissembled, cleaned, repacked, and re-assembled. (Some take oil rather than grease on the shoes, and grease in the bearings, but most of them take a buncha grease throughout.) Adjusting the bearings is really easy, once you get the hang of it. Some folks have a tendency to adjust'm too tight, especially the guys at the KT factory-- all kidding aside, most new KT and Shimano hubs come a bit tight from the factory. You want to find the sweet spot between "loose" and binding. If you can't get it 100% right, better to go a tiny bit loose than a tiny bit tight. Deorman linked to the how-to manual; there are plenty of repack how-to's on RRB and elsewhere on the internet. RRB member Udallcustombikes has a series of threads call the "UCB hub project", where he sacrifices hubs for a tear-down, and then cuts away part of the shell so you can see the innards after it's re-assembled. In my opinion, those threads are among the best on the site.

As for soap, you get that when you mix a fatty acid with an alkali salt. You can boil pig fat (lard) to render pure fat, with almost no impurities, but afterwards, you'll need to mix lye (or potash, if you don't have lye) with water and then mix that with the fats to make soap. It's more complicated then that, b/c you need precise weights and measurements to get the ratios right, and then temperature plays a big part---it's a big hassle, unless you happen to enjoy it. (I make and I sell soap--- which reminds me; I need to make more for a fund-raiser ASAP...so that's how I know about soap-making.) Not to be pedantic, but I believe that the additives in grease are detergents, and not technically "soap" in the traditional sense of the term, but i might be wrong about that. I haven't started making any DIY grease yet....

As for soap, you get that when you mix a fatty acid with an alkali salt. You can boil pig fat (lard) to render pure fat, with almost no impurities, but afterwards, you'll need to mix lye (or potash, if you don't have lye) with water and then mix that with the fats to make soap. It's more complicated then that, b/c you need precise weights and measurements to get the ratios right, and then temperature plays a big part---it's a big hassle, unless you happen to enjoy it. (I make and I sell soap--- which reminds me; I need to make more for a fund-raiser ASAP...so that's how I know about soap-making.) Not to be pedantic, but I believe that the additives in grease are detergents, and not technically "soap" in the traditional sense of the term, but i might be wrong about that. I haven't started making any DIY grease yet....

Probably 90% of coaster brake hubs you will run across come apart by removing the axle nuts from the chain side, and unscrewing the driver. The rest then slides out of the other side.

Exactly right, although I repack a Velosteel from the brake-side--- which is also the case with Perry hubs, and most Fichtel&Sachs....

I've actually got a good many 'No Brakes' coaster hubs back in operation by:

-Loosening the outer hub enough that I have a tiny space between axle and internals

-Hosing down the inside with WD-40 via the tiny extender 'straw' and letting it drip dry, and

-Doing the same again with a can of Lithium 'Chainsaw' Spray-on grease, and re-tightening.

It's pretty quick and dirty, but it lets me know whether all the components are broken or just stuck without a full teardown...

-Loosening the outer hub enough that I have a tiny space between axle and internals

-Hosing down the inside with WD-40 via the tiny extender 'straw' and letting it drip dry, and

-Doing the same again with a can of Lithium 'Chainsaw' Spray-on grease, and re-tightening.

It's pretty quick and dirty, but it lets me know whether all the components are broken or just stuck without a full teardown...