Re: Diamond Frame Flying Merkel 1/28 Crusty Saddle

So after some dead time on this build, and after surviving the Snowpocalypse mid week, I got to spend some time in the shop back home tonight.

First, I removed the chain from the bicycle. Earlier I scratched my head at the lack of a master link, but using an old awl and a nail I punched out a pin and freed the chain. I am the master link! :roll:

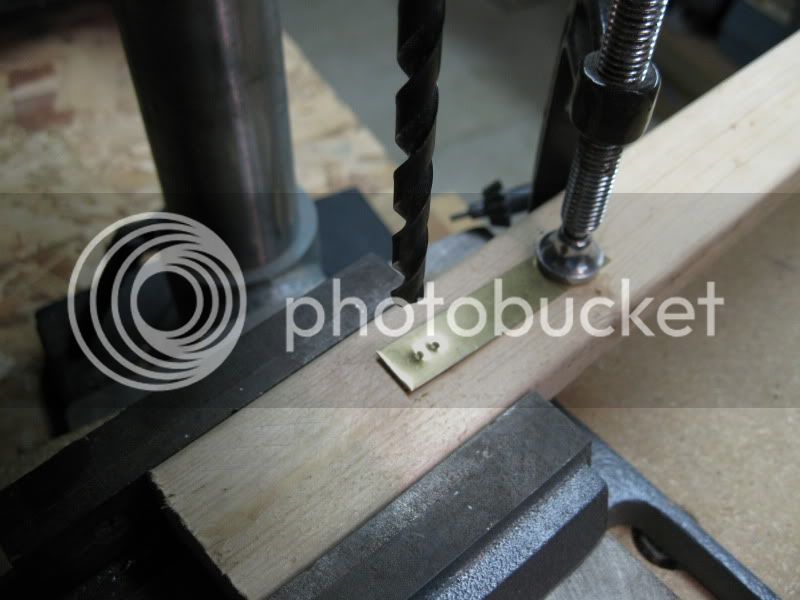

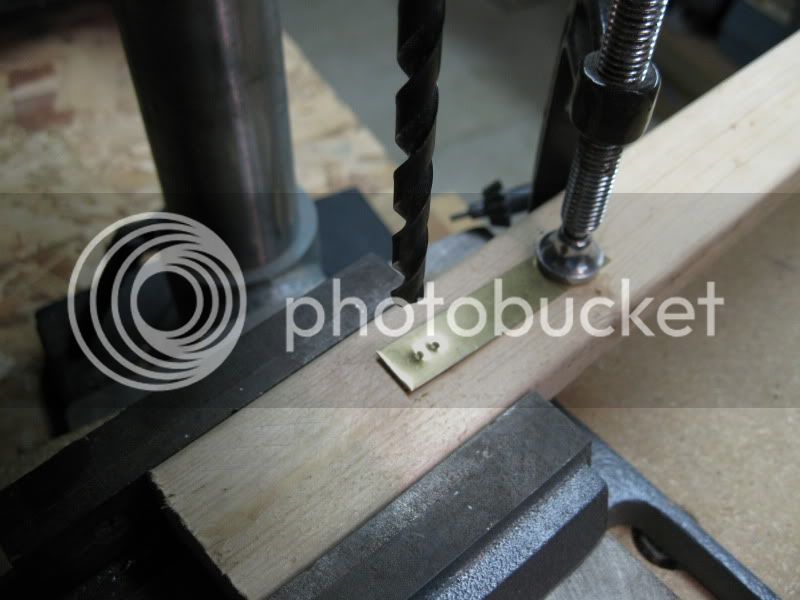

Next, I tackled the rear fender bracket. This had been broken off at some point (before I owned the bicycle) and had been held on with a piece of bent wire. Ratty! But noisy when riding. Since the bracket was nickle plated steel, I fashioned a brass tab for it and soldiered it into place. Here's the photo journey...

Finally, giddied from the overall sucess of the evening, I decided to see what my terrific truss rods would look like

Awesome, but too long. Criminently! So this will become a project too. I'm thinking either:

Difficult route: Bend the tubes near the end so that when meeting up with the drop outs on the fork, the trusses will be shorter.

Difficult-er: Mash the ends of the trusses up even more, drill new holes, cut away the excess.

Stupid: Cut the trusses in the middle, remove some sections, run a smaller OD tube inside and close it back up (mind you I don't have a welder).

Easy: un-do the trusses from the top clip, trim them, touch up the bends, re-install.

What will I do? Time will tell :| Please feel free to weigh in, sage advice is appreciated!

Tomorrow I hope ot log a bit of time in the media blaster at my place of employment to clean up the seat and truss rods, do some preliminary priming, rip the wheels to pieces, and probably break something. Stay tuned!

So after some dead time on this build, and after surviving the Snowpocalypse mid week, I got to spend some time in the shop back home tonight.

First, I removed the chain from the bicycle. Earlier I scratched my head at the lack of a master link, but using an old awl and a nail I punched out a pin and freed the chain. I am the master link! :roll:

Next, I tackled the rear fender bracket. This had been broken off at some point (before I owned the bicycle) and had been held on with a piece of bent wire. Ratty! But noisy when riding. Since the bracket was nickle plated steel, I fashioned a brass tab for it and soldiered it into place. Here's the photo journey...

Finally, giddied from the overall sucess of the evening, I decided to see what my terrific truss rods would look like

Awesome, but too long. Criminently! So this will become a project too. I'm thinking either:

Difficult route: Bend the tubes near the end so that when meeting up with the drop outs on the fork, the trusses will be shorter.

Difficult-er: Mash the ends of the trusses up even more, drill new holes, cut away the excess.

Stupid: Cut the trusses in the middle, remove some sections, run a smaller OD tube inside and close it back up (mind you I don't have a welder).

Easy: un-do the trusses from the top clip, trim them, touch up the bends, re-install.

What will I do? Time will tell :| Please feel free to weigh in, sage advice is appreciated!

Tomorrow I hope ot log a bit of time in the media blaster at my place of employment to clean up the seat and truss rods, do some preliminary priming, rip the wheels to pieces, and probably break something. Stay tuned!