Greetings RodRodders!

As I said in my introductory post, I got my first bike in 10 years last month and I have been having a blast on it. I stumbled onto this site shortly after and thought to myself- Wouldn’t it be fun to build a bike! You guys create some amazing bikes and every thread is an inspiration.

I’ve always liked working with my hands and it’s nice to use something you build. I used to shape surfboards in college but not much point doing that in Tampa. The boards I have barely see the water anymore…

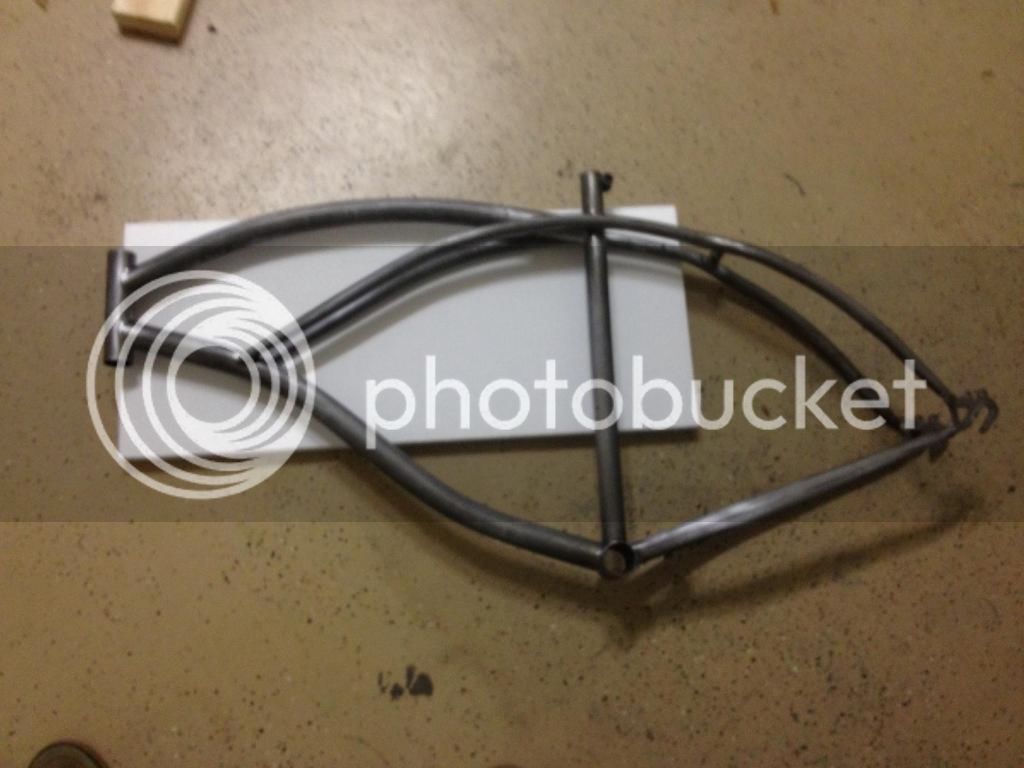

But back to the point. I picked up this bike from a junk shop this weekend. I paid $35 for it which is probably more than it’s worth. The only markings on it are a serial number (8212006) on the frame bottom bracket. The components (peddles, front brakes) are all Chinese and I couldn’t trace them to any specific manufacturer. Wheels are aluminum 26x1.75. Anybody have any idea what kind of bike it is?

More to come shortly....

As I said in my introductory post, I got my first bike in 10 years last month and I have been having a blast on it. I stumbled onto this site shortly after and thought to myself- Wouldn’t it be fun to build a bike! You guys create some amazing bikes and every thread is an inspiration.

I’ve always liked working with my hands and it’s nice to use something you build. I used to shape surfboards in college but not much point doing that in Tampa. The boards I have barely see the water anymore…

But back to the point. I picked up this bike from a junk shop this weekend. I paid $35 for it which is probably more than it’s worth. The only markings on it are a serial number (8212006) on the frame bottom bracket. The components (peddles, front brakes) are all Chinese and I couldn’t trace them to any specific manufacturer. Wheels are aluminum 26x1.75. Anybody have any idea what kind of bike it is?

More to come shortly....