Here's how I made a mudguard/fender from fibreglass.

You could use another fender as a mould but thats too easy.

I made my own mould from mdf and varying widths of 4mm thick plywood strips.I cut the mdf to a radius a bit smaller than the wheel with the tyre.Then laid the first 80mm wide strip of plywood on using screws.

Then I glued the following plywood strips on 2 at a time with epoxy resin.I had 6 in all to take me out to the desired radius for the finished fender.The first two strips were 80mm wide the next two 70mm and the last two 60mm.

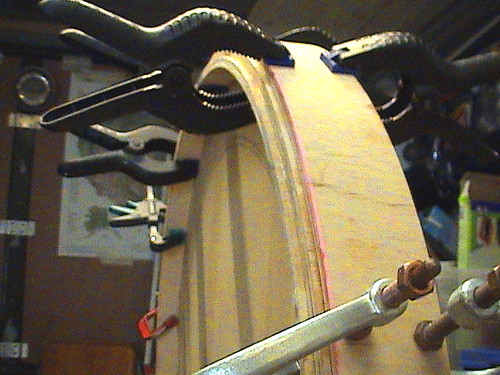

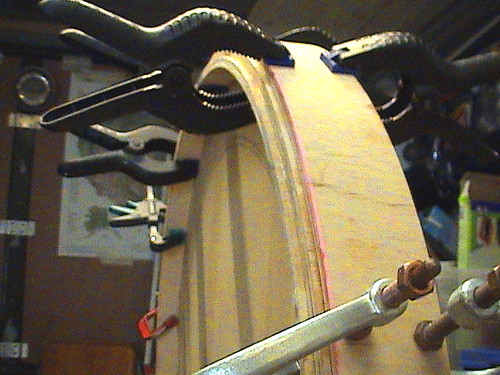

When the resin is well set go at it with your plane shaving it down to a rough outline of your mould.

After that just use some wood filler to even it up a bit and then sand it smooth.In the photo below you can see the cutout I made for the chainguard.

This is the backside of the mould with a circular cutout for a reflector

Then I put aluminium tape on the mould so I could put the releasing wax and releasing agent on.

When she's all waxed up your ready to lay up the layers of fibreglass.The best type of fibreglass cloth to use for this is called twill weave and a heavyish one.This type of weave is great for shapes which curve in more than one direction at once.

I use a trick for laying up fibreglass.First you put your piece of cloth (in this case 1m30cm x 50cm) between two sheets of polythene then mix your epoxy resin using a hardener that makes it go off slow.

Open the polythene sheets and pour your resin over the cloth (200ml was enough).Close the polythene and get an old credit card and start spreading the resin around the cloth.Like this you get an extremely even spread of resin and all the excess ends up at the edges.You can then draw cut lines on the top of the polythene (every 100mm/4inches).This method is also infinitely less messy and cutting the cloth is very easy.

Paint a thin layer of resin on the mould and then lay the strips on one at a time not forgetting to remove the polythene!!

The reflector recess needs a plug so that the wet cloth will take the shape properly,the plug needs to be waxed too so it won't stay stuck.

Let it dry for 24hours.One point I have to make at this stage is that when I had the mould made I realised that the mudguard was more than half a circle so I was concerned that it wouldn't come off anymore when it was dry so I cut a wedge out of the middle.Before cutting out the wedge I made some key plates so it would go back together correctly.With the wedge space it was possible to "break" the mould and make it much easier to remove the fender.

After that just trim it,apply body filler,sand it,drill your holes and paint it.Ordinary stays can be use to install it but I made my own.It's getting painted at the moment but when it's installed I'll pu up a foto.

Its not a cheap way of acquiring a mudguard,or an easy one,but now I know I can make any fender in any size.The possibilities for integrally moulding recesses or protusions,maybe for housing lights,makes this a potentially interesting new way to customize and also a way of answering an apparently long standing question.

Here are some photos of the finished thing

You could use another fender as a mould but thats too easy.

I made my own mould from mdf and varying widths of 4mm thick plywood strips.I cut the mdf to a radius a bit smaller than the wheel with the tyre.Then laid the first 80mm wide strip of plywood on using screws.

Then I glued the following plywood strips on 2 at a time with epoxy resin.I had 6 in all to take me out to the desired radius for the finished fender.The first two strips were 80mm wide the next two 70mm and the last two 60mm.

When the resin is well set go at it with your plane shaving it down to a rough outline of your mould.

After that just use some wood filler to even it up a bit and then sand it smooth.In the photo below you can see the cutout I made for the chainguard.

This is the backside of the mould with a circular cutout for a reflector

Then I put aluminium tape on the mould so I could put the releasing wax and releasing agent on.

When she's all waxed up your ready to lay up the layers of fibreglass.The best type of fibreglass cloth to use for this is called twill weave and a heavyish one.This type of weave is great for shapes which curve in more than one direction at once.

I use a trick for laying up fibreglass.First you put your piece of cloth (in this case 1m30cm x 50cm) between two sheets of polythene then mix your epoxy resin using a hardener that makes it go off slow.

Open the polythene sheets and pour your resin over the cloth (200ml was enough).Close the polythene and get an old credit card and start spreading the resin around the cloth.Like this you get an extremely even spread of resin and all the excess ends up at the edges.You can then draw cut lines on the top of the polythene (every 100mm/4inches).This method is also infinitely less messy and cutting the cloth is very easy.

Paint a thin layer of resin on the mould and then lay the strips on one at a time not forgetting to remove the polythene!!

The reflector recess needs a plug so that the wet cloth will take the shape properly,the plug needs to be waxed too so it won't stay stuck.

Let it dry for 24hours.One point I have to make at this stage is that when I had the mould made I realised that the mudguard was more than half a circle so I was concerned that it wouldn't come off anymore when it was dry so I cut a wedge out of the middle.Before cutting out the wedge I made some key plates so it would go back together correctly.With the wedge space it was possible to "break" the mould and make it much easier to remove the fender.

After that just trim it,apply body filler,sand it,drill your holes and paint it.Ordinary stays can be use to install it but I made my own.It's getting painted at the moment but when it's installed I'll pu up a foto.

Its not a cheap way of acquiring a mudguard,or an easy one,but now I know I can make any fender in any size.The possibilities for integrally moulding recesses or protusions,maybe for housing lights,makes this a potentially interesting new way to customize and also a way of answering an apparently long standing question.

Here are some photos of the finished thing