You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

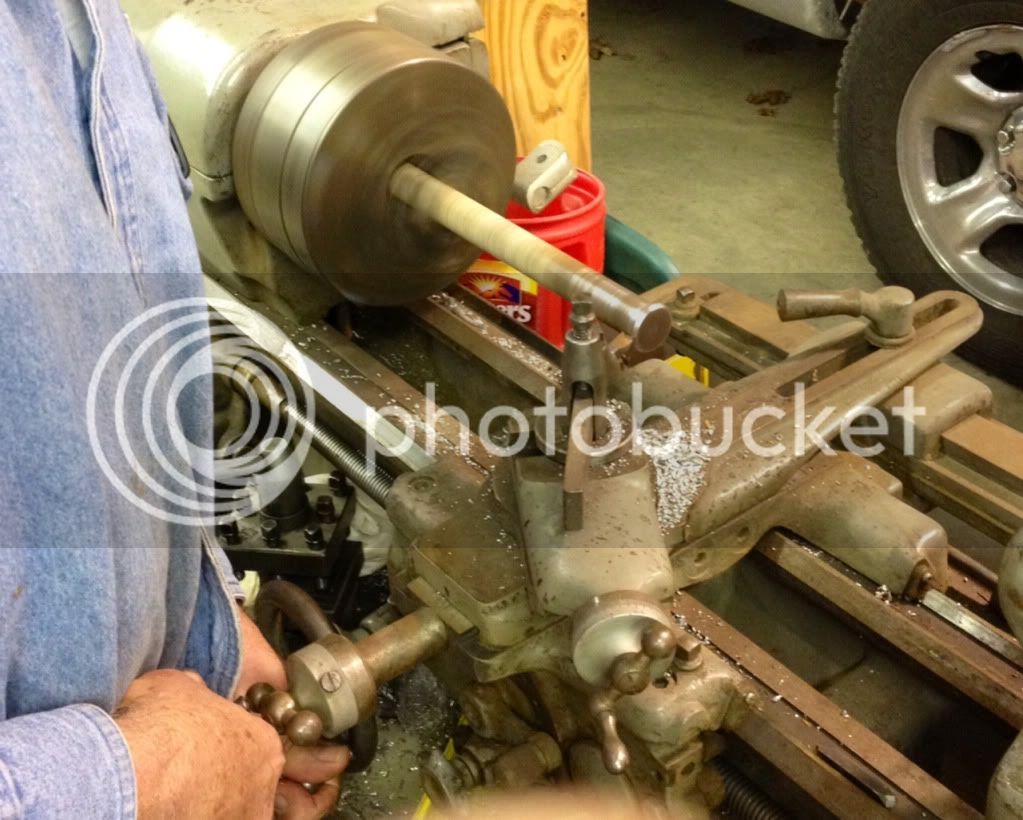

home made seat post

- Thread starter layflat78

- Start date

Help Support Rat Rod Bikes Bicycle Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

yoothgeye

I build stuff.

Looks good, did you cool the heated bend or let it cool itself? The reason I ask is that I used to cool my "hot stuff" with water until I learned that this weakened the heated part, but if you cool with oil it actually strengthens it. A little messier, and you get a cool flare us sometimes, but I like things to be strong.

I don't know though how forced cooling compares to letting it cool naturally.

I don't know though how forced cooling compares to letting it cool naturally.

yoothgeye

I build stuff.

layflat78 said:I let it air cool. I was about to drop it in some water, but my Dad stopped me and told me about making it weak.

Nice.

Nice work!

Feel free to send it to me at....... :wink: :mrgreen:

Cheers,

Dr. T

Feel free to send it to me at....... :wink: :mrgreen:

Cheers,

Dr. T

Dr. Tankenstein said:Nice work!

Feel free to send it to me at....... :wink: :mrgreen:

Cheers,

Dr. T

Thanks Dr. T this is my first on many! I have a bunch of "scrap" stock I can get for free. The horizontal is too long on this one for my seat so I am going to turn 3 or 4 more this weekend to try and get it just right.

layflat78 said:I let it air cool. I was about to drop it in some water, but my Dad stopped me and told me about making it weak.

it actually "over hardens" it and makes it brittle, oil quenching works because it cools slower than water, but you can spray water on it and get similar effects if you do it right.. (how re-bar is tempered)

Heating and quenching steel makes it harder and more brittle, but I would hesitate in calling it "weaker". When we heat treated parts in the machine shop where I worked we heated the parts in an oven then quenched them. Then, they were heated again at a much lower temperature to "draw back the temper" which removed the brittleness and gave the part both hardness and enough elasticity that it wouldn't break. Proper heat treating and annealing is an art and there's a lot more to it than torching a part and sticking it in water. Gary

B607 nails it.

In general, (depending on the steel somewhat) since you let your bend air cool, the area of your bar with the heat color is now softer and more bendable than the silver ends. Probably makes little practical difference for your seat post, but could be critical in a high stress application.

In general, (depending on the steel somewhat) since you let your bend air cool, the area of your bar with the heat color is now softer and more bendable than the silver ends. Probably makes little practical difference for your seat post, but could be critical in a high stress application.

Hopefully not a stupid question but if the steel is softer when left to cool on its' own would it be better for a part such as a seat post were a little "flex" would be beneficial assuming it is not so soft as to stay bent?

Awesome job. But with a solid seat post isn't it kind of heavy. Could you make the same post with heavy wall tubing? Would bending it be a problem? I've heard of people filling it with sand and welding the ends shut before attempting the bending process. Thanks for getting me thinking. Gary

yoothgeye

I build stuff.

CHAMPION123 said:Awesome job. But with a solid seat post isn't it kind of heavy. Could you make the same post with heavy wall tubing? Would bending it be a problem? I've heard of people filling it with sand and welding the ends shut before attempting the bending process. Thanks for getting me thinking. Gary

I believe the old "Lucky 7" posts were solid, but I've never held one in my hand.

As for weight, we are only concerned with weight on our road bikes and mountain bikes, classics, rats, cruisers, it's all out the window.

Yes, you can make the seat with a piece of tube and your described method has been done on this site.

CHAMPION123 said:Awesome job. But with a solid seat post isn't it kind of heavy. Could you make the same post with heavy wall tubing? Would bending it be a problem? I've heard of people filling it with sand and welding the ends shut before attempting the bending process. Thanks for getting me thinking. Gary

I guess I could have made it out of heavy wall tubing, but I didn't have any laying around. Also, with the post going from 13/16" to 5/8" I thought it would be easier to use solid rod. I honestly was not thinking about weight at all. Just trying to get experience on the lathe, spend some time with my Dad, drink a few beers and make a simple seat post. I did pick up some more scrap rod at my buddies machine shop this week so I am going to make a few more this weekend. I was able to ride with the one I made, it held my 220lbs just fine!

I aggree with you. Thinking about it, I think the old lucky 7 posts were solid. I don't have much time on a lathe either. I think you did an awesome job. Plus using materials that you already have is what it's all about and you made it yourself. Spend as much time with your dad as you can. I miss my dad every day. I'm glad the seat post worked for you. Thanks again for posting, Gary.

Heavy duty is probably worth the solid at your weight, I am questioning the sections I have cut from motorcycle handlebars for even my 205#s, though no trouble so far.

As another route to a post I need to get down to my local auto salvage yard to look at old solid jack handles, it the post size is right for my Western flyer I can cut the ends off and grind the post clamp tip, file up and paint. I think those are close to a spring steel.

As another route to a post I need to get down to my local auto salvage yard to look at old solid jack handles, it the post size is right for my Western flyer I can cut the ends off and grind the post clamp tip, file up and paint. I think those are close to a spring steel.