You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How Many Cad Engineers, Designers, Draftsmen Here?

- Thread starter motopsyco

- Start date

Help Support Rat Rod Bikes Bicycle Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I'll let CP and the others show you great drawings of fine components. 8)

You can count on me for the semi acceptable drawings of the low rent stuff...

Here's a Kalin stem that I bought 2 for a 1.99 on ebay

I put on of them on the Huffy I just built. Just couldn't go wrong at that price.

You can count on me for the semi acceptable drawings of the low rent stuff...

Here's a Kalin stem that I bought 2 for a 1.99 on ebay

I put on of them on the Huffy I just built. Just couldn't go wrong at that price.

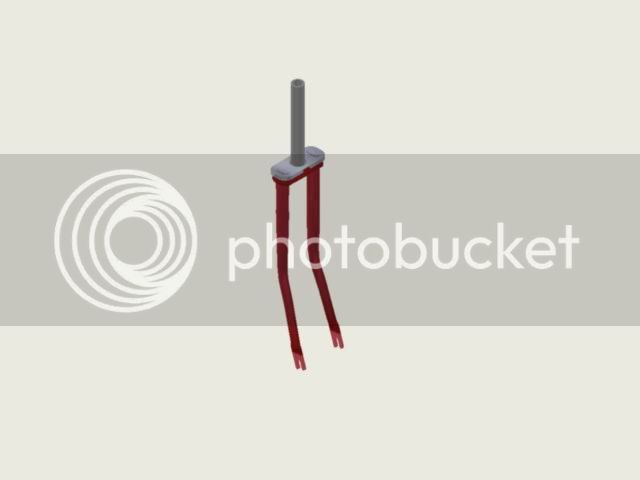

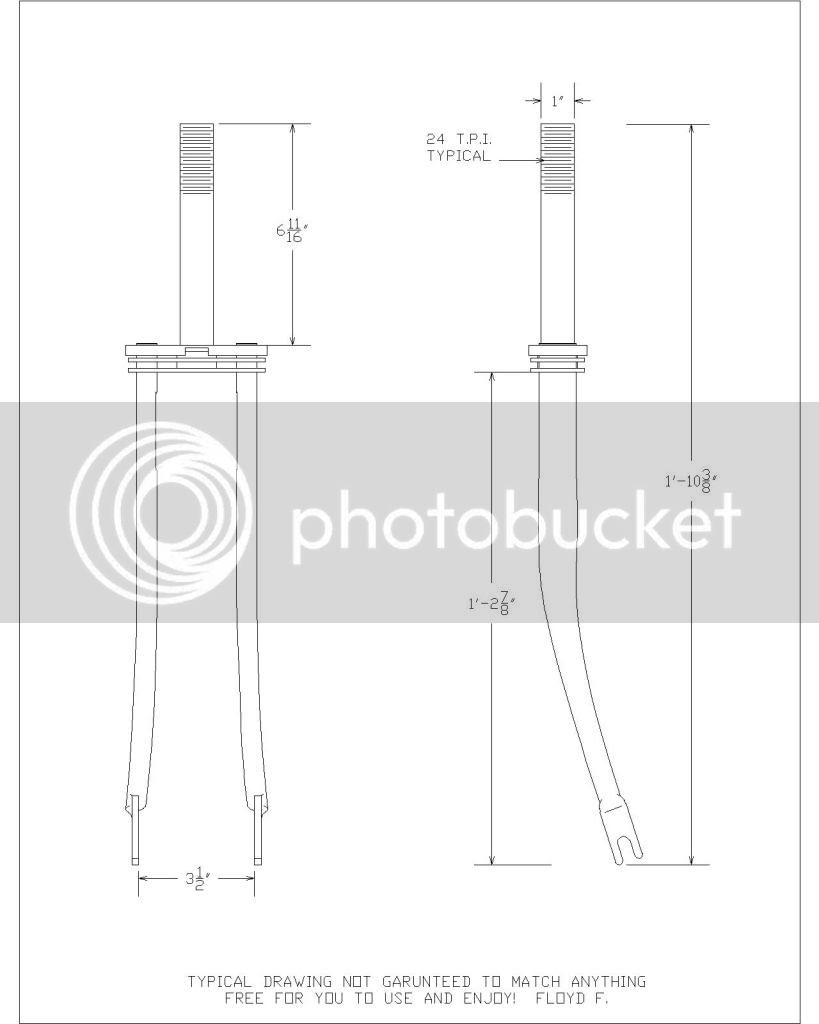

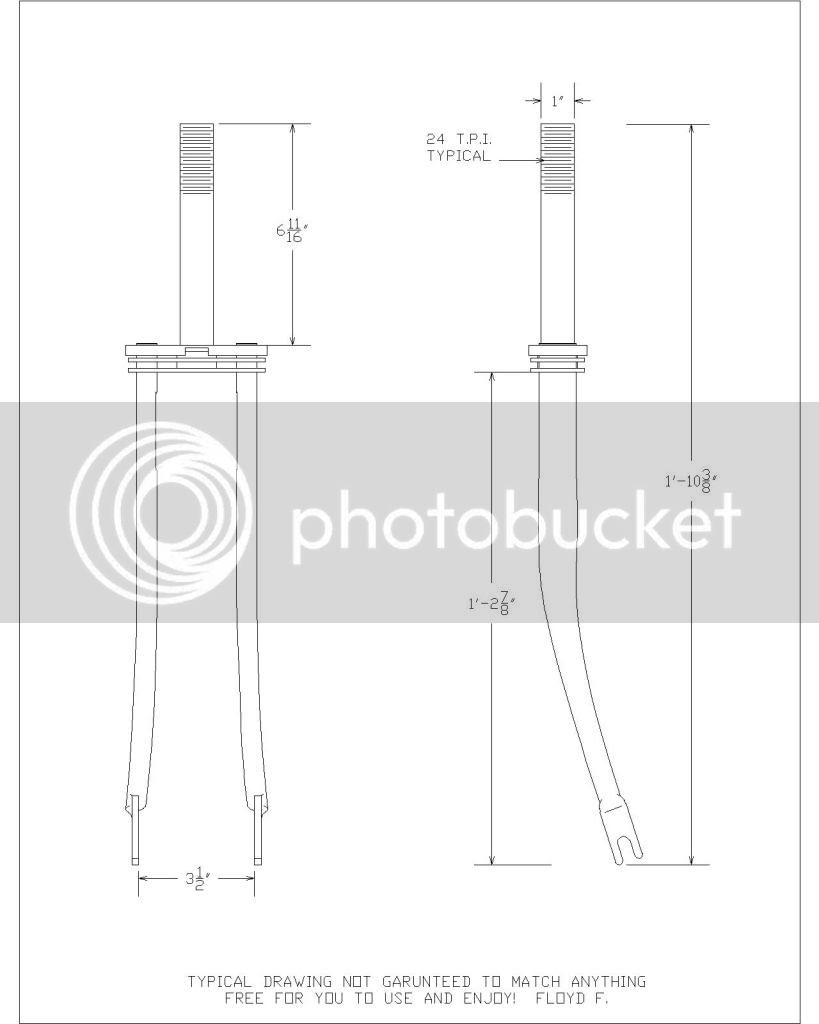

Had the original Huffy fork from my last project lying around and decided to do a 3d model of it. Turns out the build quality of this thing (old U.S. made Huffy), well lets just say it has generous assembly tolerances. :roll: But hey as long as the slots at the bottom are aligned and the stem is straight and centered that was all that counted. The only way I noticed was by measuring it all over with a pair digital calipers. So I just decided to draw a generic fork based on the dimensions of this one.

Here's the model;

and here's a print style drawing with dimensions

Here's the model;

and here's a print style drawing with dimensions

Moto;

Way to step it up. Nice job on the stem. Got a couple of them waiting to be done.

I will need to dig up some more stuff and post.

Your an SolidWorks driver, how about my SW lug challenge? The problem is keeping the profile cut normal the the curved surface. I failed at this in SW but I am an amateur at that program, completed it in Pro-E.

Way to step it up. Nice job on the stem. Got a couple of them waiting to be done.

I will need to dig up some more stuff and post.

Your an SolidWorks driver, how about my SW lug challenge? The problem is keeping the profile cut normal the the curved surface. I failed at this in SW but I am an amateur at that program, completed it in Pro-E.

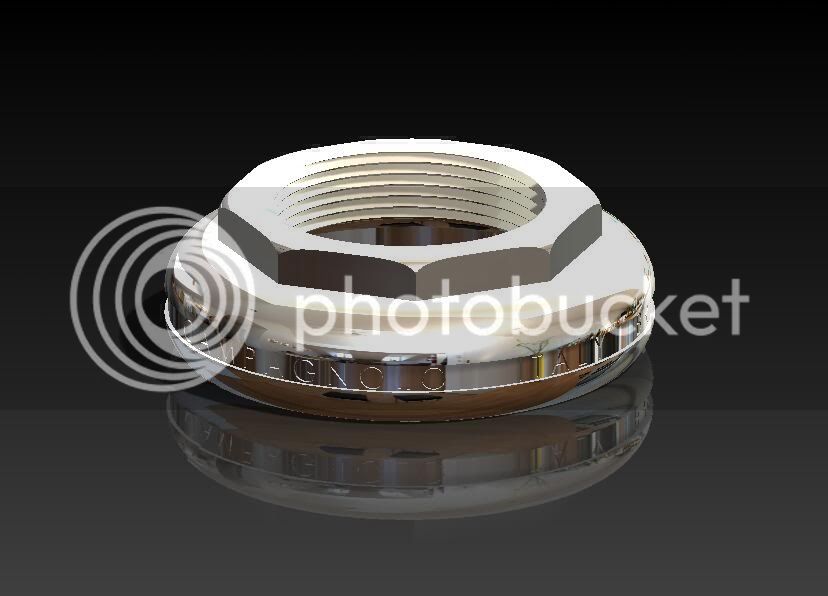

This is the toughest part I have ever done in SolidWorks. This part is three layers merged together. The parts are created flat and then wrapped (bent into a curved). The wrapping is to complicated for all the details to be bent at once. So a body was created with only one detail (stipples, Campagnolo, Nouvo Record) on it at a time then bent. The three finished models were then merged together. This involved several weeks of failure before I hit on the right methodology.

c.p.odom said:Moto;

Way to step it up. Nice job on the stem. Got a couple of them waiting to be done.

I will need to dig up some more stuff and post.

Your an SolidWorks driver, how about my SW lug challenge? The problem is keeping the profile cut normal the the curved surface. I failed at this in SW but I am an amateur at that program, completed it in Pro-E.

I don't currently have access to a licensed copy of SW. Everything I am doing now is in Autocad. They have really stepped up the 3d capability.

It's about time for another Solidworks test drive with free trial edition software :wink:

What's really sad is that my employer considers 3d to be a waste of time... except when it saves his bacon and impresses customers of course.

$83.21

$89.18

Hot Cams 7.48mm Complete Shim Kit HCSHIM01 for Honda CRF Kawasaki KX Suzuki RMZ Yamaha WR YZ Dirt Bikes

oemcycles

$19.99

Electra Glide Wall Decal 2ft Long Sport Harley Davidson Bike Motorcylce Sticker Man Cave Garage Boys Room Decor

FatCat Wall Graphics

$24.99

Top Brass Bicycle/Motorcycle Chain Picture Frame 5" X 7" Photo - Faux Bike Chain

Old River Outdoors (USA Merchant)