that was thrown away.

a very brief back story.

as a product of the 80s and early 90s, I quickly realized that I was a bit different than my peers, my dad drove a 1954 buick roadmaster and my mom made our house feel like a museum. my parents were both professional designers, my mom, an interior designer and my dad an architect. After i graduated high school in 03, I went the route that many of us did, being lazy and feeling like i would never amount to anything. I got a associates degree in graphic design but never really liked it or chased a career in it. I had odd jobs here and there including a hot rod shop, vintage car parts shop, network admin, and even the pottery barn. I got a break and landed in a major motion picture studio here in LA. Working with the art department, I was fascinated with props and sets. after some soul searching I decided to go back to school and get a degree in industrial design while working part time at a special effects shop. this, my thesis project, has gone through many versions until a full scale mockup was built.

I was sitting on a train from san diego to la, and i was sitting next to a guy that was very talkative and inquisitive. we got on the topic of collecting things and it soon became apparent that he was a collector of bicycles, modern mountain bikes. I told him about my collection of pre and post war bikes and he was very interested. he knew of one classic bike, that shall remain nameless. it wasnt made of tubing but rather a composite.

taking a new approach to a vintage groundbreaking bike was the aim. I took a walk through the train and sat down in the observation deck, i got a napkin and a piece of paper and went to town. after thinking about it for the rest of the day, I threw the napkin away when i got off the train and decided it was going to be my thesis. I dont really know why i threw it away, but i think if i hadn't it would have gone by the wayside.

later that week i wrote up a proposal and to my utter astonishment, it was accepted. that was about 11 weeks ago.

I set to work on computer drawings and models.

Revision 1

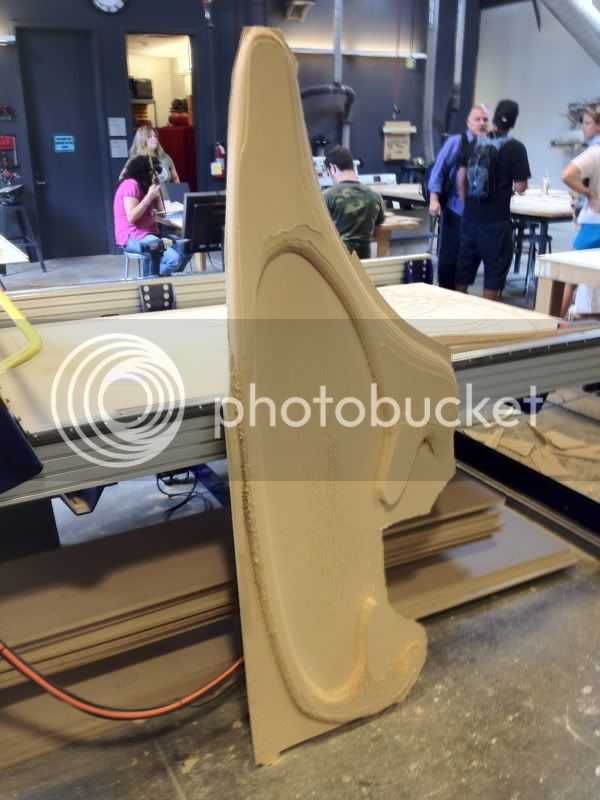

heres the unfinished model (note front fender/fork)

I decided to go another route, In knowing that i wanted to create a full scale mockup this bike, I felt that the support bars were a bit out of place and distracting from the shape of the rest of the bike.

on to rev 2.

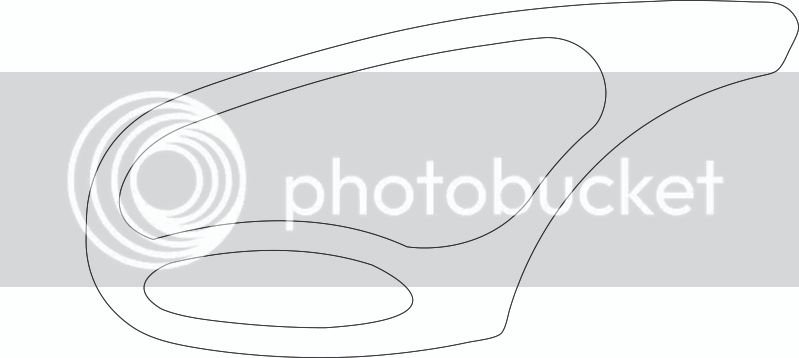

(this is actually a full scale vector that i scaled down, dont know why it looks kind of weird.

on to modeling.

Im trying to simplify this as much as possible, but there was a lot of work between each of these steps, between stress testing, design tweaks, small scale models (printed on a 3d printer)

anyway, ill get to the juicy.

we started with MDF wood, 3- 3/8, 4x8 sheets laminated together. with some tweaking we were able to get both halves of the frame on one sheet, but first we had to trick our cnc router (we have a horrible cam program)

we dialed it in pretty well, but the shops vac system was a bit overwhelmed by the amount of dust and chunks created by it.

the actual process to cut each side took about 14 hours a piece. each layer or step took about half an hour. since the vac system was struggling, i had to watch, and vaccum for all 28 hours that it was running. long nights.

more on this later.

a very brief back story.

as a product of the 80s and early 90s, I quickly realized that I was a bit different than my peers, my dad drove a 1954 buick roadmaster and my mom made our house feel like a museum. my parents were both professional designers, my mom, an interior designer and my dad an architect. After i graduated high school in 03, I went the route that many of us did, being lazy and feeling like i would never amount to anything. I got a associates degree in graphic design but never really liked it or chased a career in it. I had odd jobs here and there including a hot rod shop, vintage car parts shop, network admin, and even the pottery barn. I got a break and landed in a major motion picture studio here in LA. Working with the art department, I was fascinated with props and sets. after some soul searching I decided to go back to school and get a degree in industrial design while working part time at a special effects shop. this, my thesis project, has gone through many versions until a full scale mockup was built.

I was sitting on a train from san diego to la, and i was sitting next to a guy that was very talkative and inquisitive. we got on the topic of collecting things and it soon became apparent that he was a collector of bicycles, modern mountain bikes. I told him about my collection of pre and post war bikes and he was very interested. he knew of one classic bike, that shall remain nameless. it wasnt made of tubing but rather a composite.

taking a new approach to a vintage groundbreaking bike was the aim. I took a walk through the train and sat down in the observation deck, i got a napkin and a piece of paper and went to town. after thinking about it for the rest of the day, I threw the napkin away when i got off the train and decided it was going to be my thesis. I dont really know why i threw it away, but i think if i hadn't it would have gone by the wayside.

later that week i wrote up a proposal and to my utter astonishment, it was accepted. that was about 11 weeks ago.

I set to work on computer drawings and models.

Revision 1

heres the unfinished model (note front fender/fork)

I decided to go another route, In knowing that i wanted to create a full scale mockup this bike, I felt that the support bars were a bit out of place and distracting from the shape of the rest of the bike.

on to rev 2.

(this is actually a full scale vector that i scaled down, dont know why it looks kind of weird.

on to modeling.

Im trying to simplify this as much as possible, but there was a lot of work between each of these steps, between stress testing, design tweaks, small scale models (printed on a 3d printer)

anyway, ill get to the juicy.

we started with MDF wood, 3- 3/8, 4x8 sheets laminated together. with some tweaking we were able to get both halves of the frame on one sheet, but first we had to trick our cnc router (we have a horrible cam program)

we dialed it in pretty well, but the shops vac system was a bit overwhelmed by the amount of dust and chunks created by it.

the actual process to cut each side took about 14 hours a piece. each layer or step took about half an hour. since the vac system was struggling, i had to watch, and vaccum for all 28 hours that it was running. long nights.