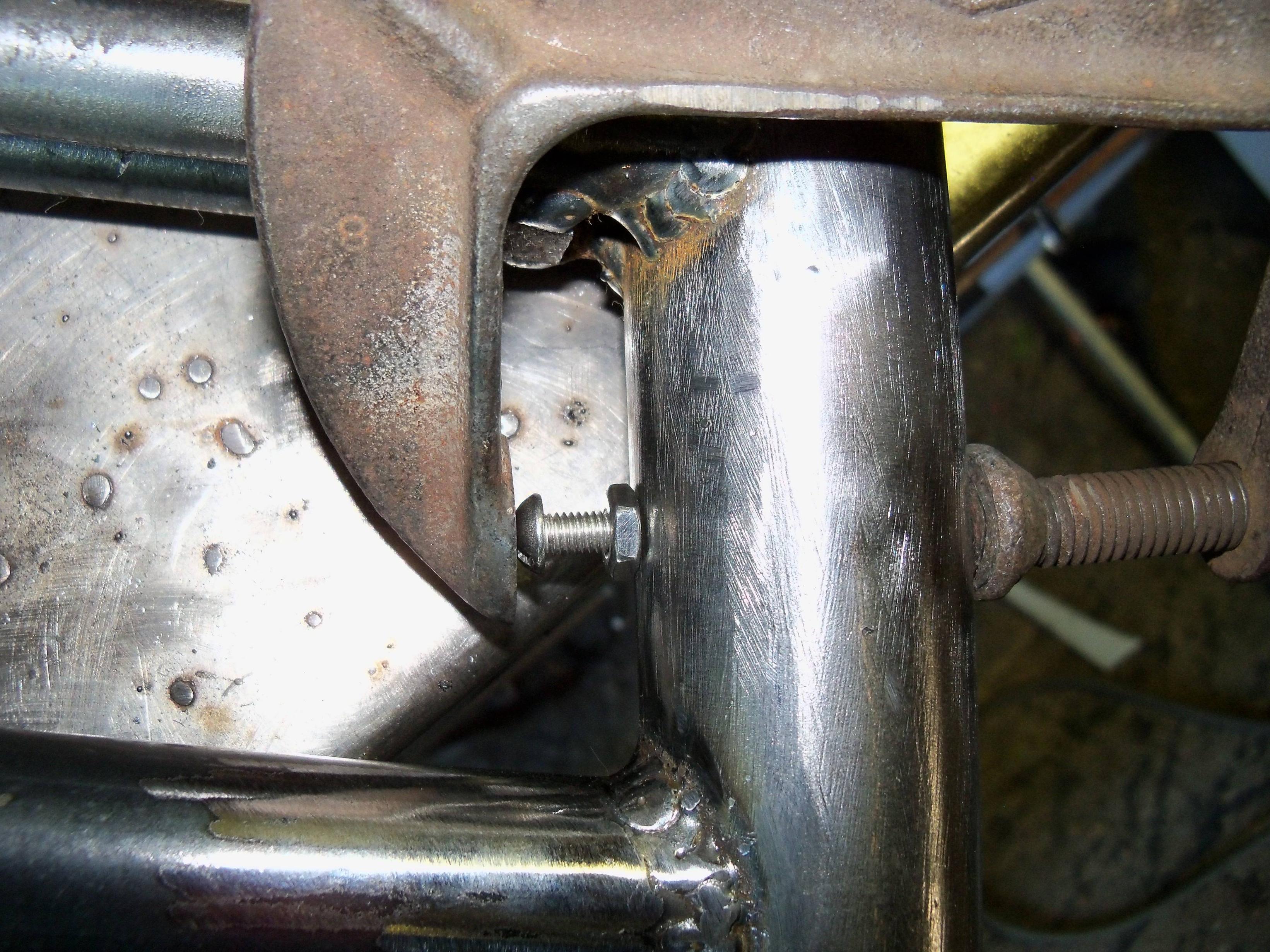

In keeping with the "fatty" theme I decided to put the WCC fork on with the 20x3 tire. I slammed the fork down as low as it could go (for a reason to be seen later). After I took the pic's I put the chain on and took her for a quick spin. I wanted to see how the cranks cleared, they looked low. It has plenty of clearance for turning! She rides GREAT, even without the top fork cup and bearing and no brake... lol

Last edited:

Tough!

Tough!