You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ryo's Rat/Hot/Cafe-Rod Bike Build (temporarily revived!)

- Thread starter Ryoskate

- Start date

Help Support Rat Rod Bikes Bicycle Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Sorry for the lack of updates. I quit my part time and have been slow going with the project BUT! I got a OCC stingray fork for free today and it's hellova lot better than the springer fork!

But ofcourse, they don't come close to fitting without modification. So I've decided to finally rake my frame so I can get the low looks I want without the fear of face-planting into hard concrete.

Mocking up to see how much rake I need and trail it'll give.

No turning back now...

Before:

After:

Tack-welded until I can get better at welding. lol....

Will work on shortening the fork tomorrow. No regrets on swapping from that bent suicide springer forks. Anyone still using that thing is asking for trouble.

Seems like this thing will never get a motor.

But ofcourse, they don't come close to fitting without modification. So I've decided to finally rake my frame so I can get the low looks I want without the fear of face-planting into hard concrete.

Mocking up to see how much rake I need and trail it'll give.

No turning back now...

Before:

After:

Tack-welded until I can get better at welding. lol....

Will work on shortening the fork tomorrow. No regrets on swapping from that bent suicide springer forks. Anyone still using that thing is asking for trouble.

Seems like this thing will never get a motor.

Much safer with those forks than a bent springer!

Luke.

Luke.

Completely messed up the weld on the frame... going to let someone else do it for me. Thin walled tubing with a buzz box welder isn't a good idea.

But, I did finish the Stingray triple tee fork, rode around the block and it's STURDY. My god, how did I even ride around with that other fork.

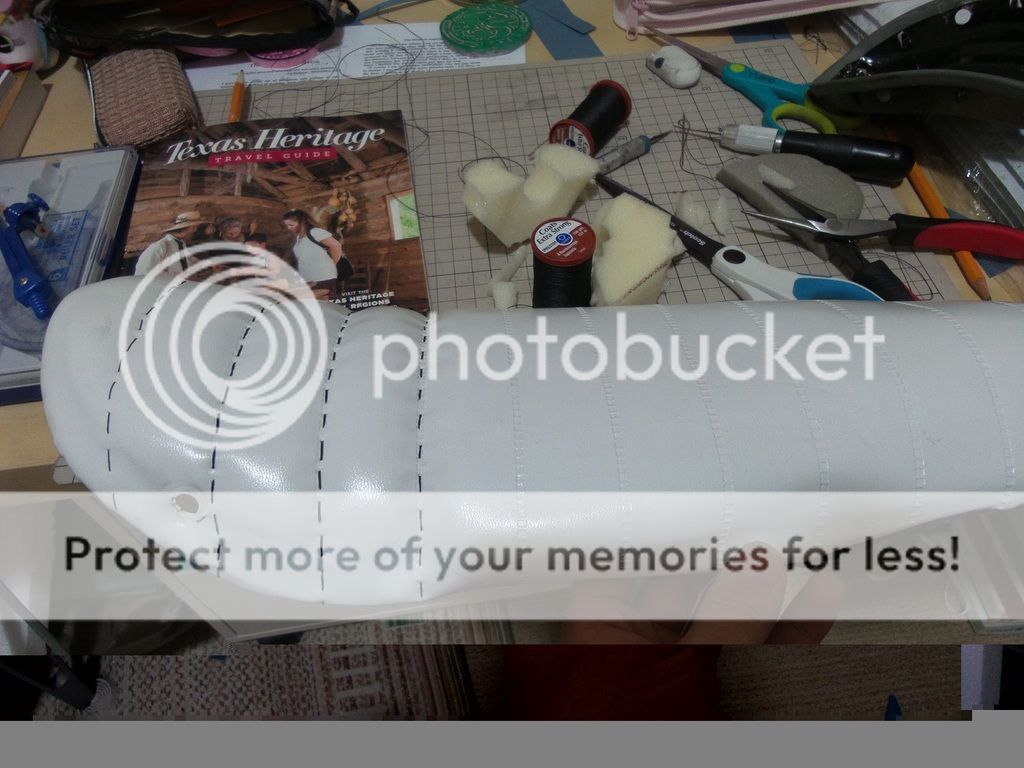

I also cut the Inner frame of the banana seat to match the width of the tank.

Also cut and welded the handle bar that came with the bike to something a little more sportier. This weld, I did a lot better on since it was pretty thick.

I think I'll finally get the motor for Christmas instead of fixing the Datsun.

But, I did finish the Stingray triple tee fork, rode around the block and it's STURDY. My god, how did I even ride around with that other fork.

I also cut the Inner frame of the banana seat to match the width of the tank.

Also cut and welded the handle bar that came with the bike to something a little more sportier. This weld, I did a lot better on since it was pretty thick.

I think I'll finally get the motor for Christmas instead of fixing the Datsun.

Last edited by a moderator:

I think I'll finally get the motor for Christmas instead of fixing the Datsun.

Luke.

$29.95

Crossroads Home Décor A Biker's Prayer, Gift for Motorcycle Riders, Inspirational Bike Picture Frame, 6451BW

Crossroads_Home_Decor

$19.99

Electra Glide Wall Decal 2ft Long Sport Harley Davidson Bike Motorcylce Sticker Man Cave Garage Boys Room Decor

FatCat Wall Graphics

Nice work on that seat mount!

Luke.

Luke.

Sweet Seat! . Not much in to bikes with motors but really like your fab work. Are the downtube addtions just for a motor mount? or help with strength.

It's a little bit of both but mainly for the Engine mount. These poorly balanced motors are notorious for cracking frames.

Found a huge flaw today... The Dual pull Brake lever just doesn't work for me... It gets caught and never pulls 2 at the same time...

Also the fact that the rim wasn't built for cantilever brakes didn't help either...

Also the fact that the rim wasn't built for cantilever brakes didn't help either...

Sanded the rim, cleaned it, and shortened the brake lines... Seemed to have done the trick, both sides pulls evenly now.

I had really long brake lines since I was just mocking it up, but the kinks that the line made the break not work well...

I still need to fabricate something to hold down the front calipers better. It's really janky.

I had really long brake lines since I was just mocking it up, but the kinks that the line made the break not work well...

I still need to fabricate something to hold down the front calipers better. It's really janky.

Made a little something today.

Feel free to copy the idea if you like... I don't plan on producing anything I make.

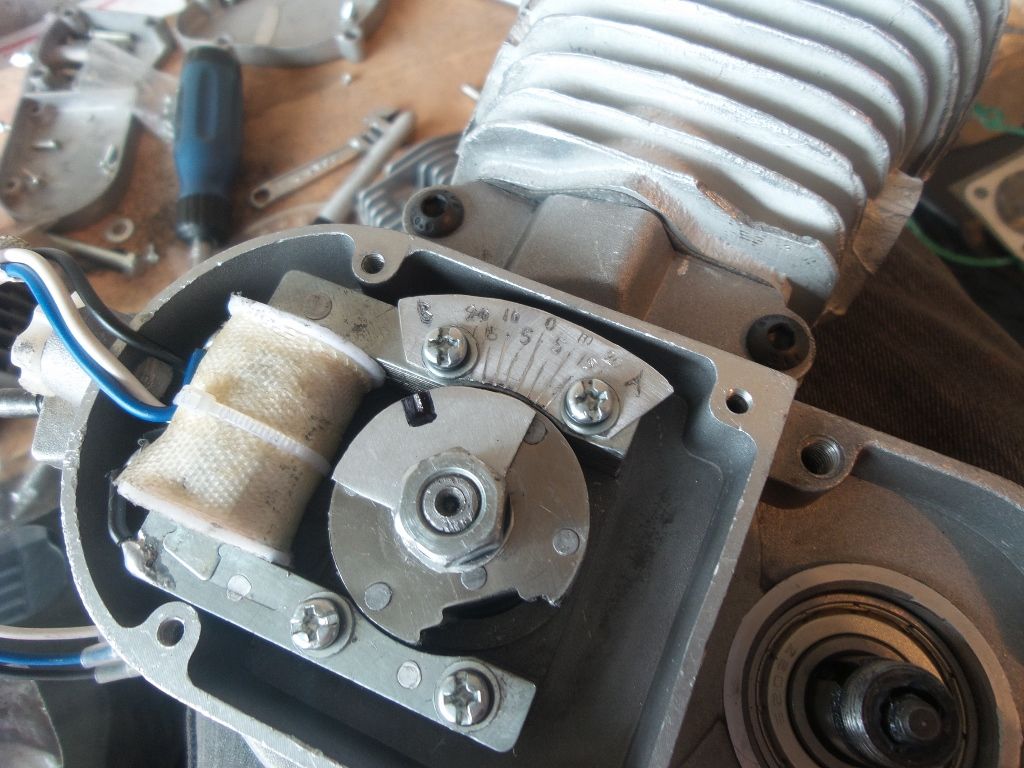

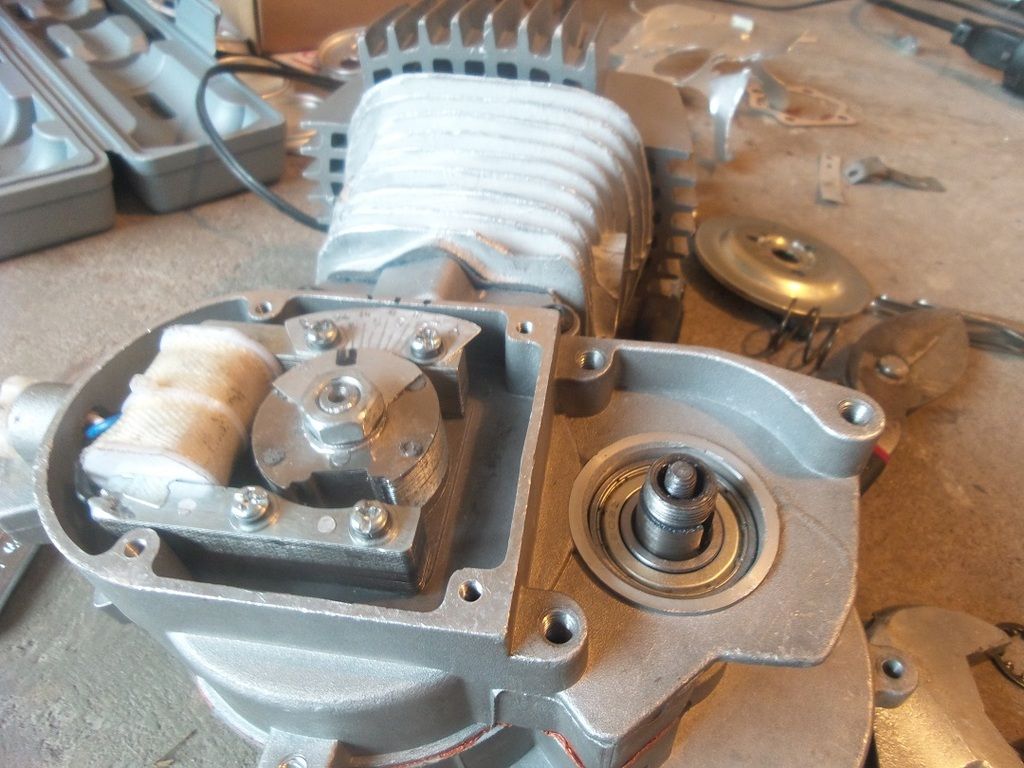

Also made a tool to match the combustion chamber to the piston shape.

Reshaped combustion chamber... To the best of my abilities with the tools I have.

After clay testing, I got the squishband down to 1.2mm with the gasket on... So I try without any gaskets and ended up with .6, which was what I was looking for. However when I went to assemble the motor, it seems that I didn't get an accurate reading with the clay test, piston hit the head while hand turning the motor.

I put the gasket back on for now but I'm afraid it doesn't have a good contact surface with the puch head. I will have to re-check tommorow.

Feel free to copy the idea if you like... I don't plan on producing anything I make.

Also made a tool to match the combustion chamber to the piston shape.

Reshaped combustion chamber... To the best of my abilities with the tools I have.

After clay testing, I got the squishband down to 1.2mm with the gasket on... So I try without any gaskets and ended up with .6, which was what I was looking for. However when I went to assemble the motor, it seems that I didn't get an accurate reading with the clay test, piston hit the head while hand turning the motor.

I put the gasket back on for now but I'm afraid it doesn't have a good contact surface with the puch head. I will have to re-check tommorow.

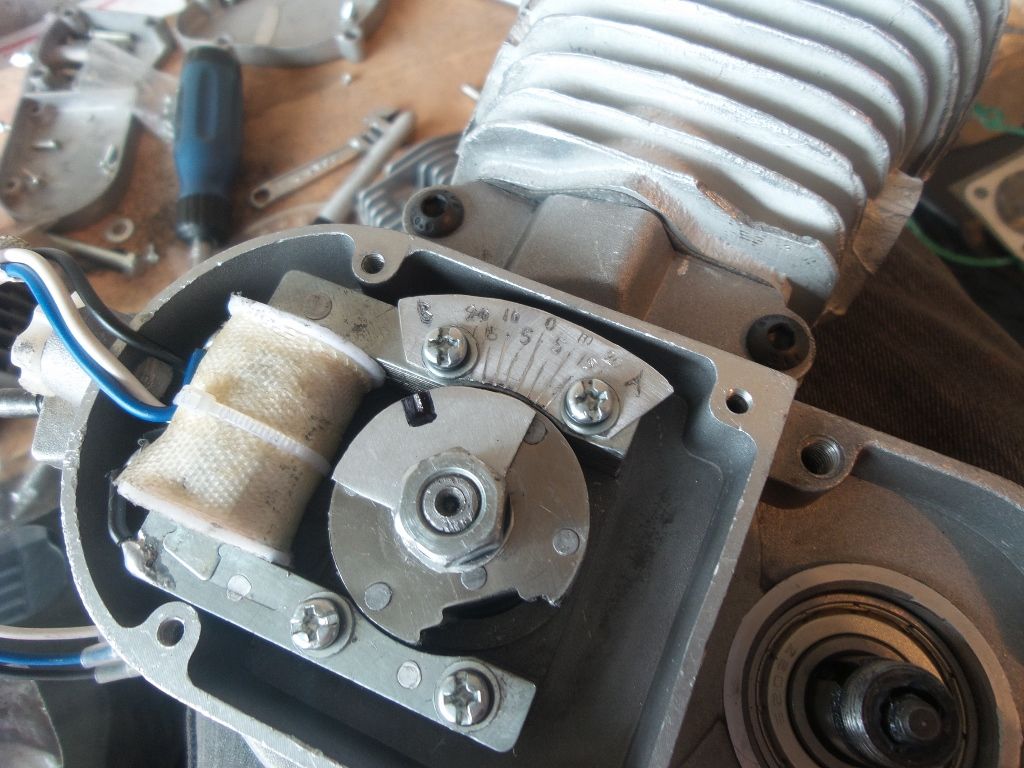

Spot the rookie mistake.

And yes, I had to tear down the whole motor over again.

Anyways, should I keep the Patina-Orange gas tank or paint it the same color as the rest of the bike? Decisions decisions...

And yes, I had to tear down the whole motor over again.

Anyways, should I keep the Patina-Orange gas tank or paint it the same color as the rest of the bike? Decisions decisions...

Got a few days worth of pictures to share. It was a pretty lazy weekend.

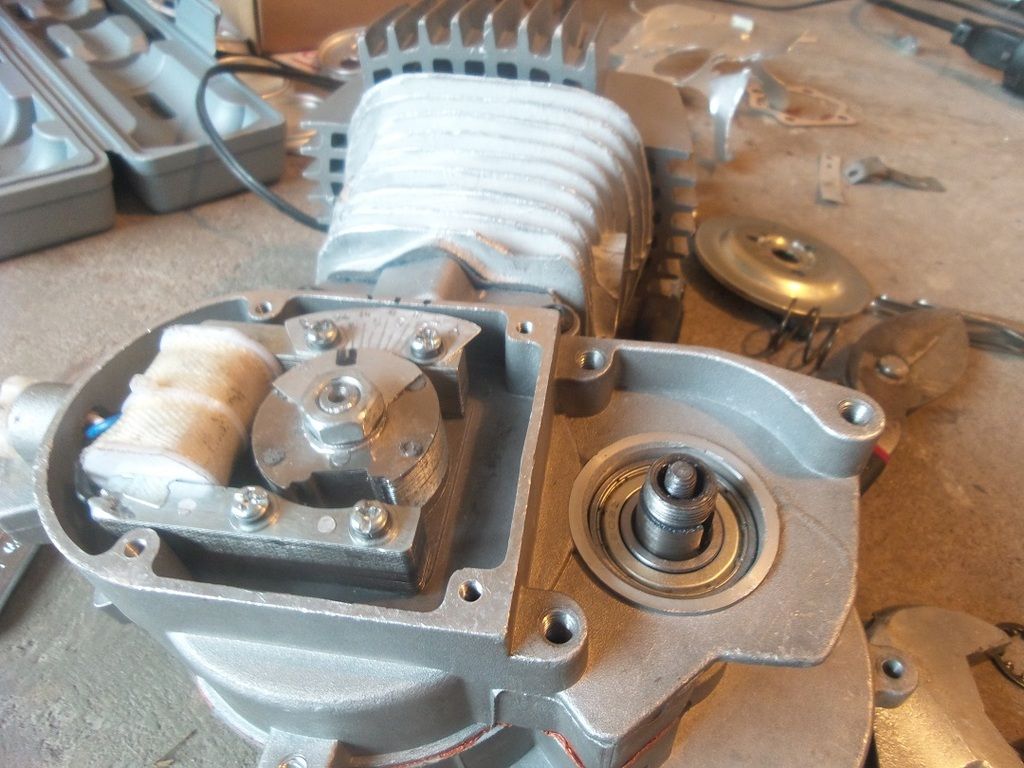

Solely for looks, I decided to use a Puch exhaust / baffle for my motor.

Chopped to re-angle / lengthen some of the parts using the remains of my handlebar, it was conveniently the same OD. ID was slightly smaller but not by much.

End result. I grinded the welds for a cleaner look and to check for leaks. It's really pain in the arse doing this with a $100 Harbor freight fluxcore mig.

What remains of my handle bar...

Solely for looks, I decided to use a Puch exhaust / baffle for my motor.

Chopped to re-angle / lengthen some of the parts using the remains of my handlebar, it was conveniently the same OD. ID was slightly smaller but not by much.

End result. I grinded the welds for a cleaner look and to check for leaks. It's really pain in the arse doing this with a $100 Harbor freight fluxcore mig.

What remains of my handle bar...