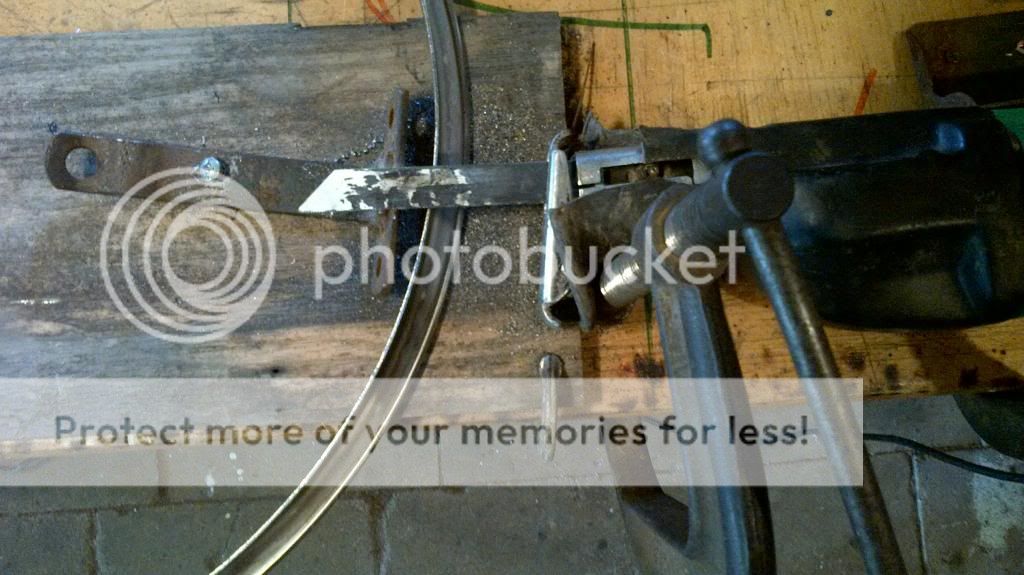

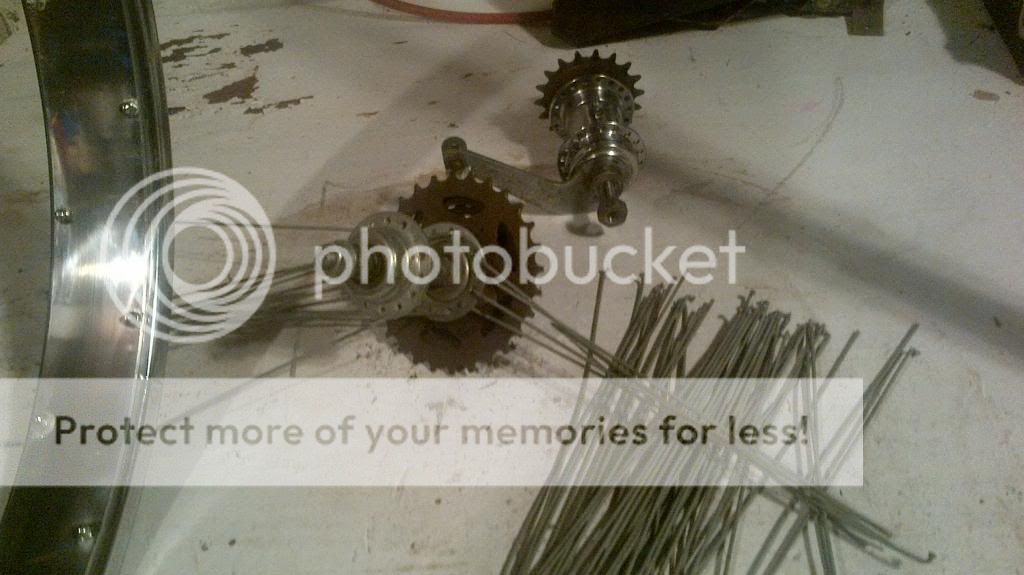

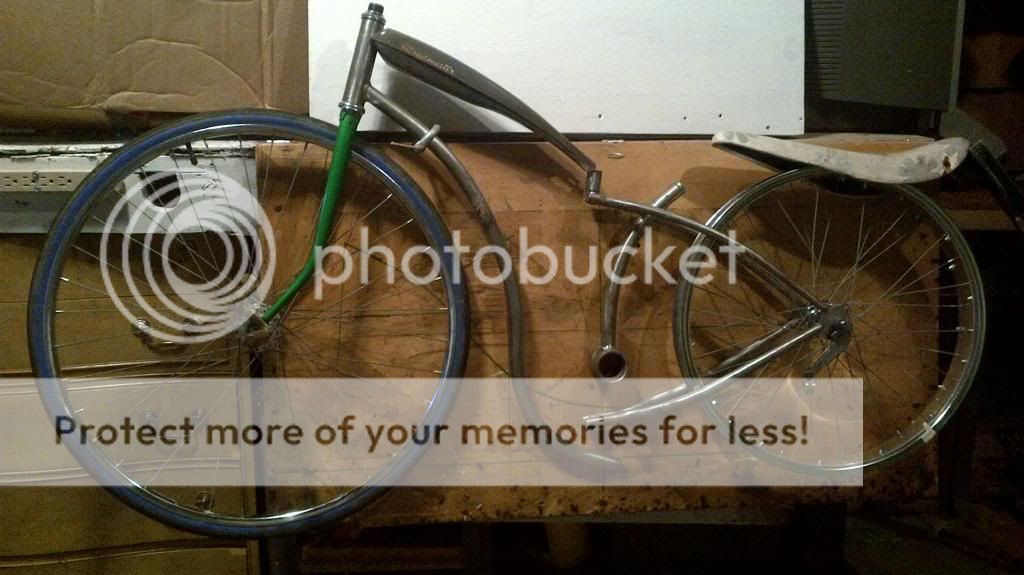

Starting with a pile of un-related stuff, frame stripped of paint, unknown fork, 27 x 1 1/4 wheel. 24 inch MTB rims

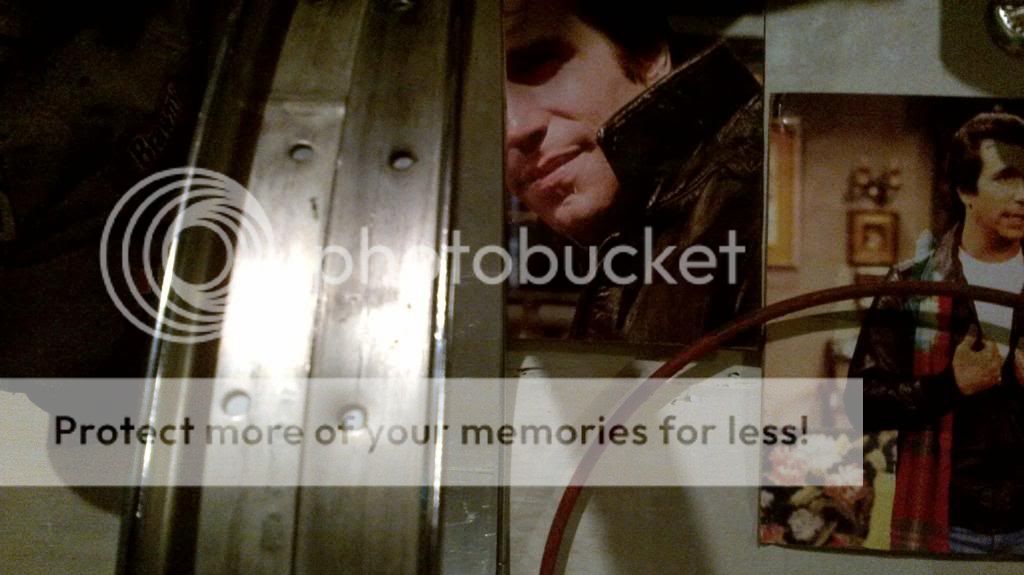

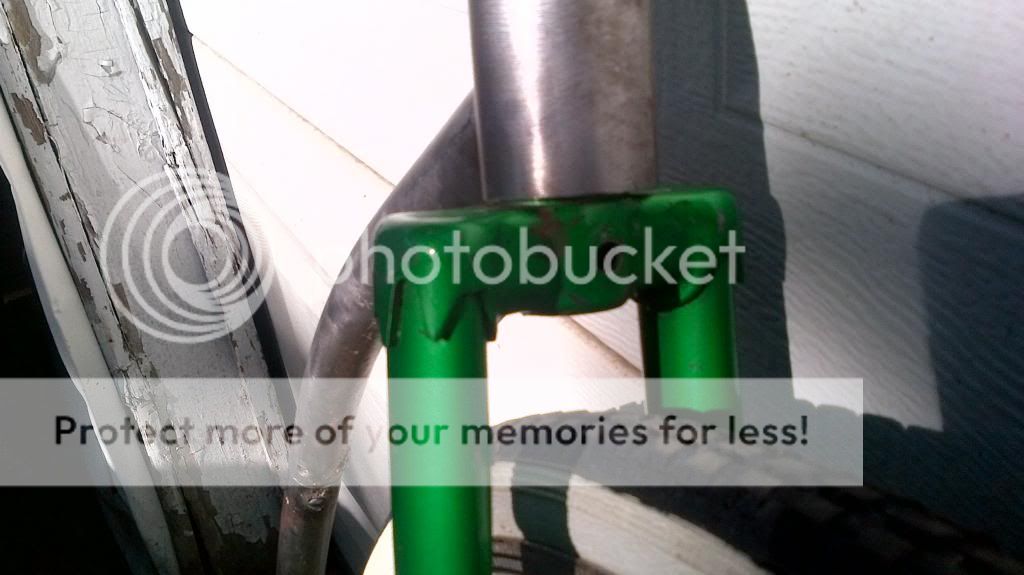

Going for something like this, with a seat built on the rear fender. Plans are to shorten the length of the frame, widen the rear and get the down tube right on top of and following the front tire better.

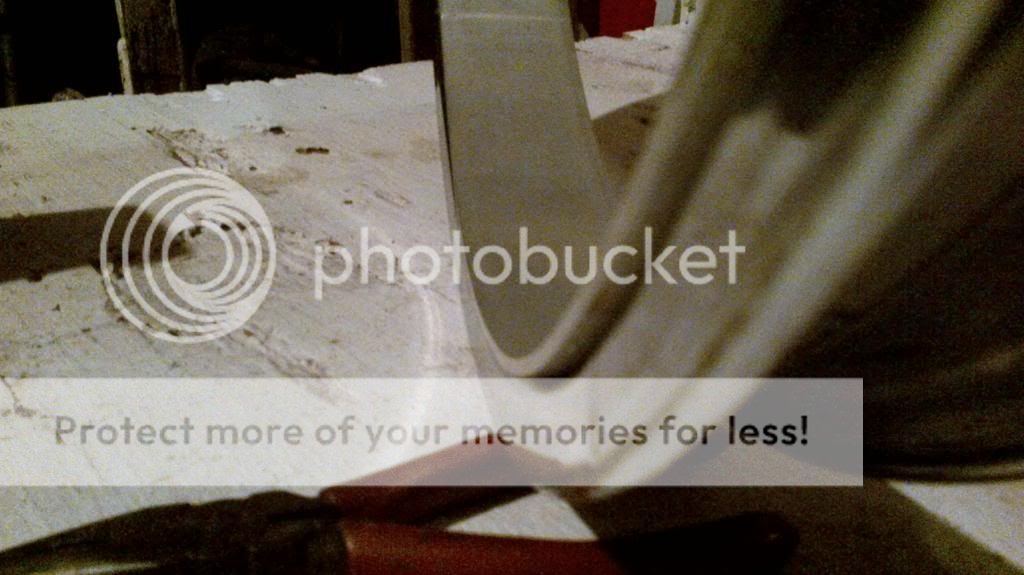

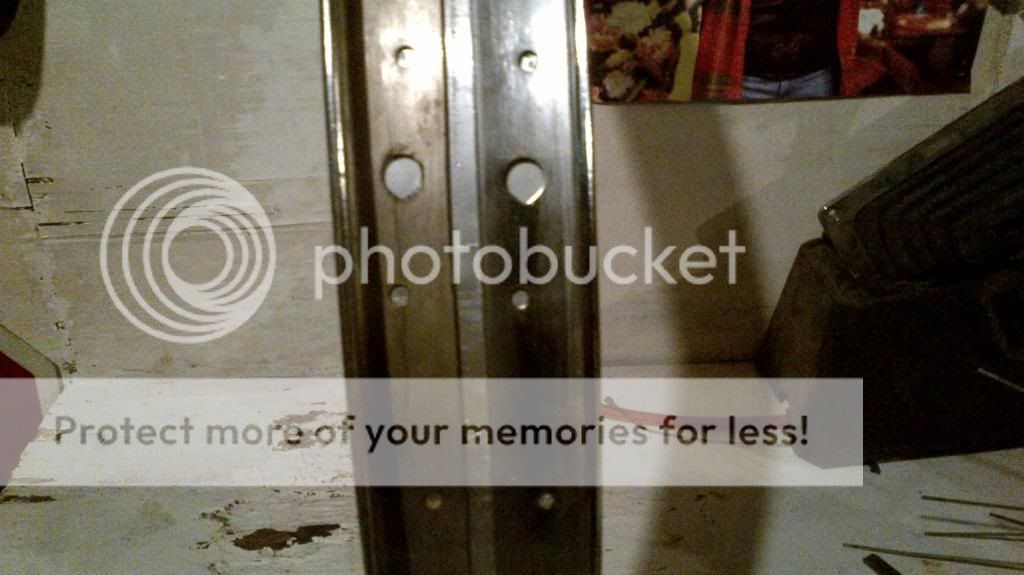

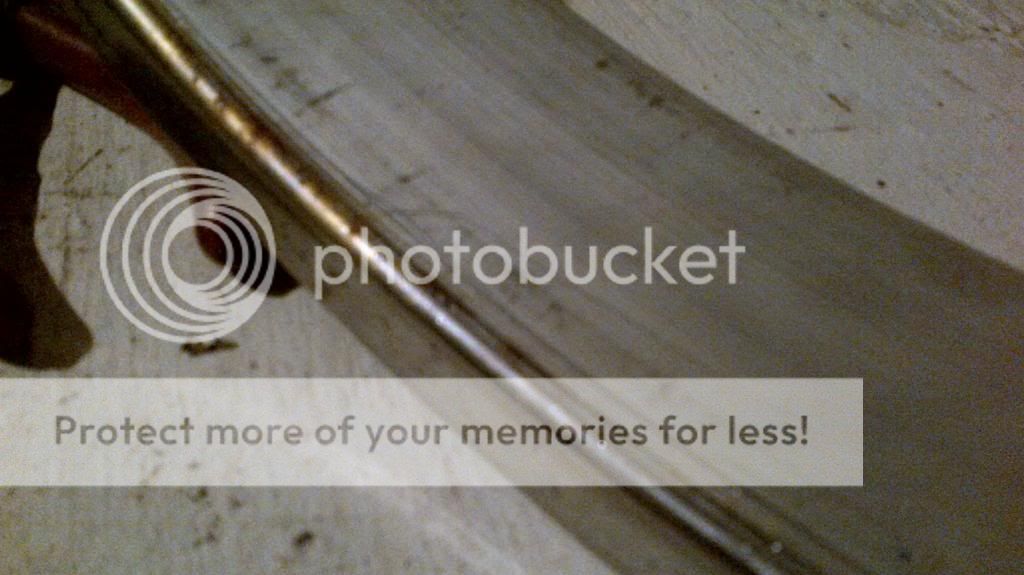

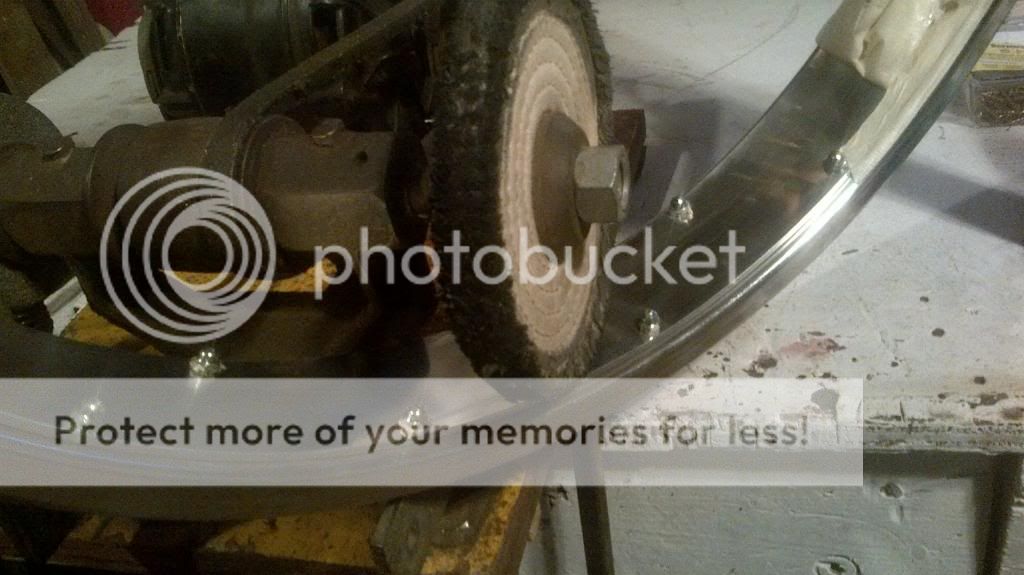

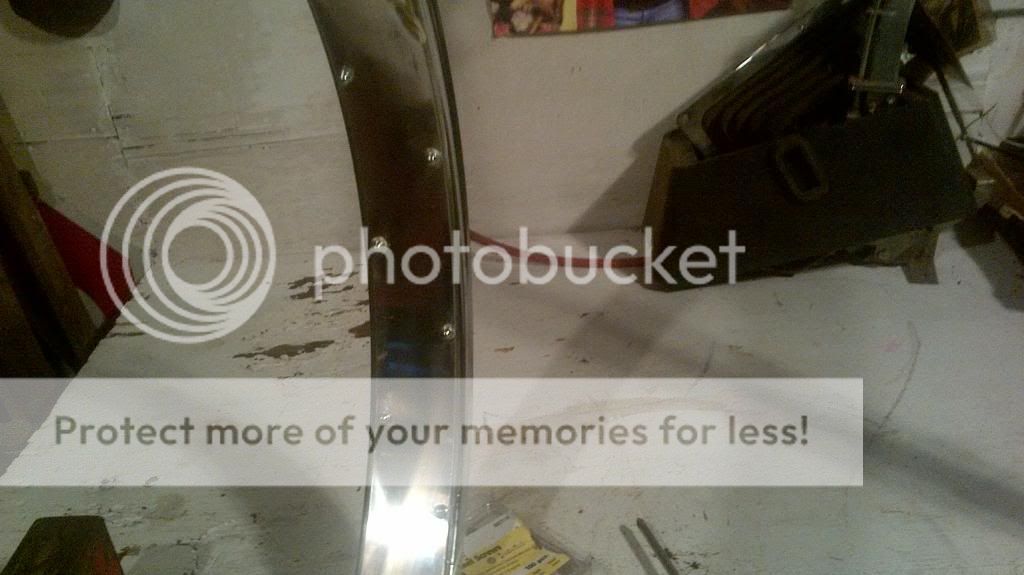

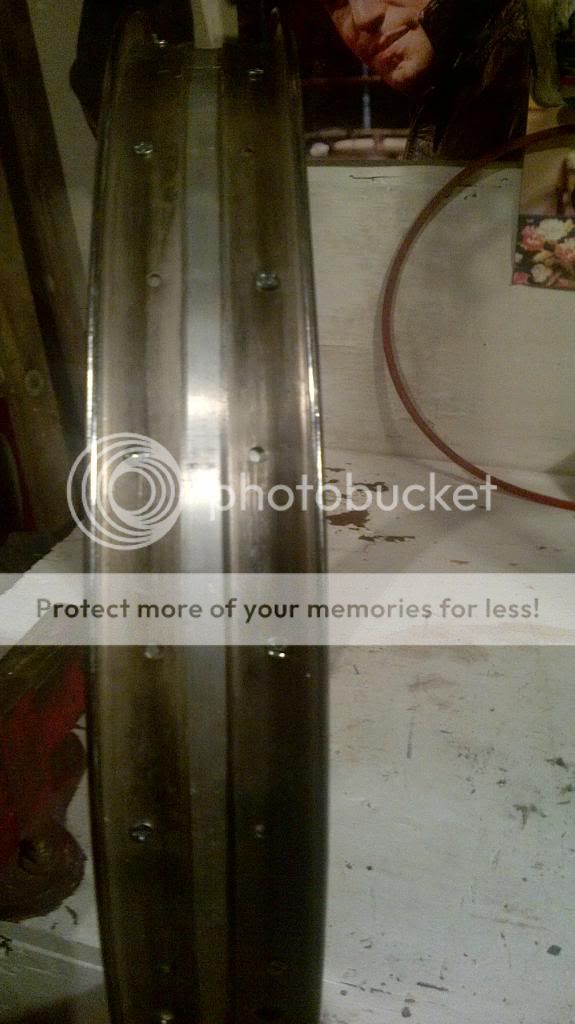

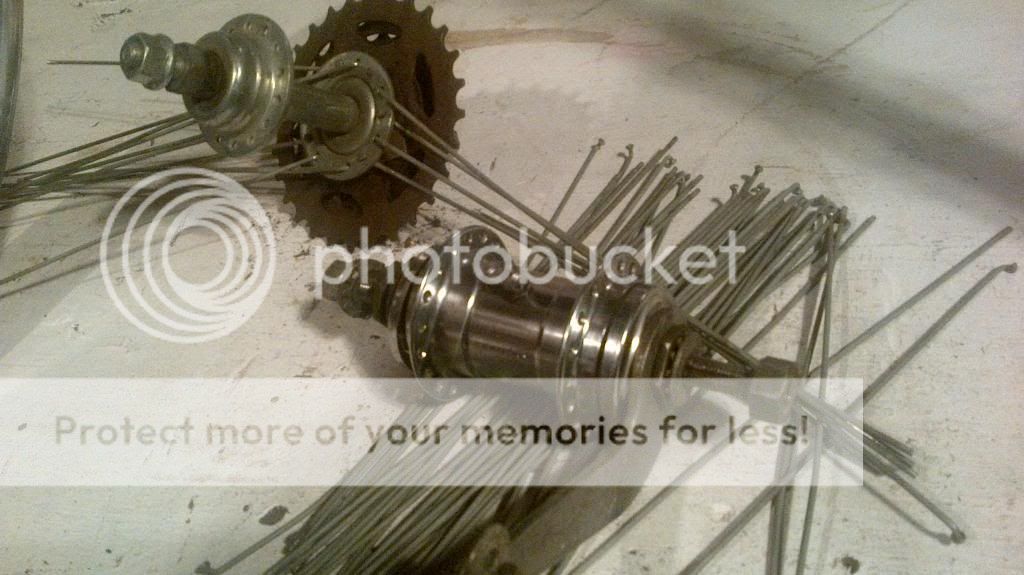

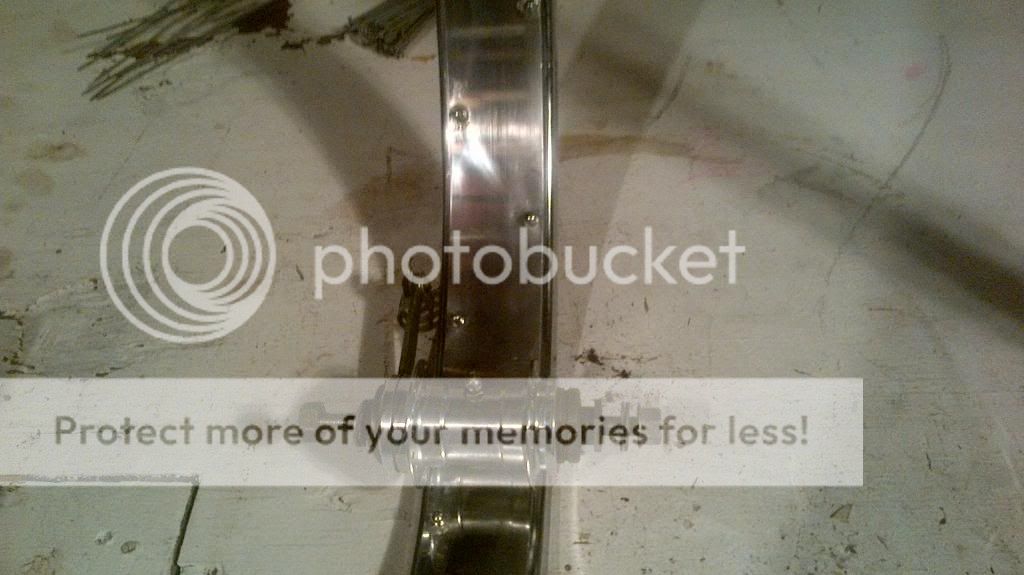

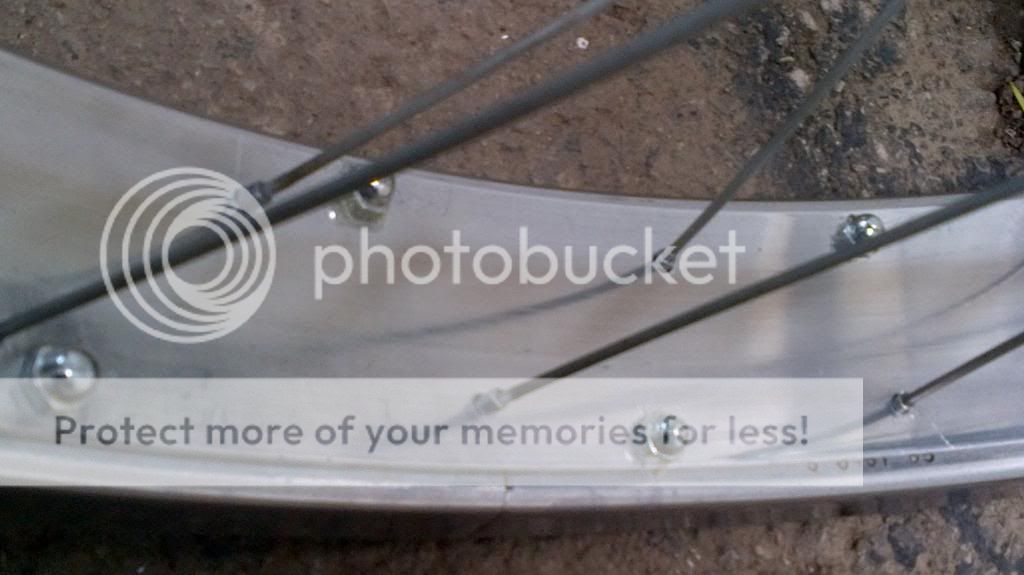

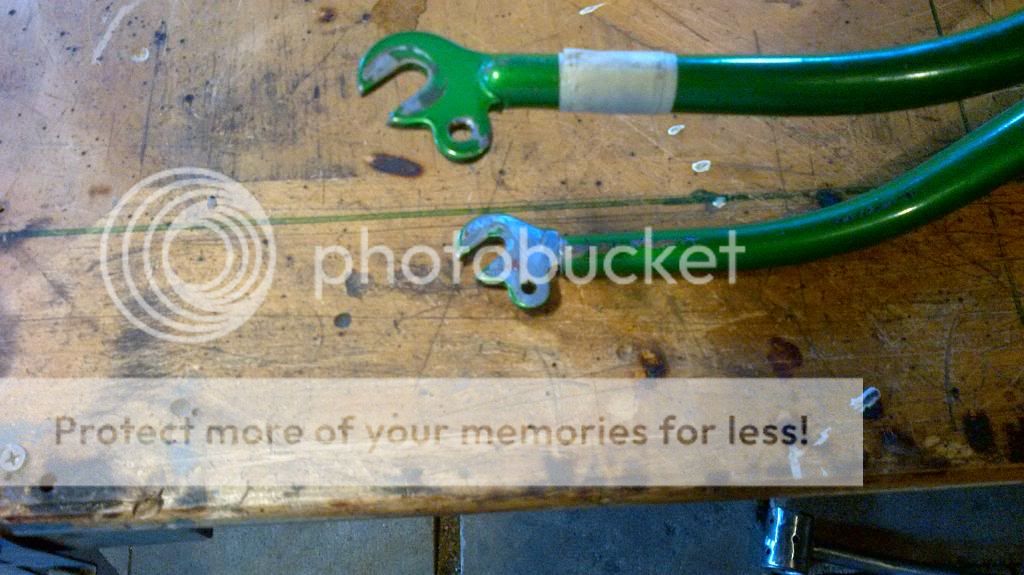

Unlaced the 24 " wheels, going to cut 1 side off each and reattach into 1 wide rim.

Going for something like this, with a seat built on the rear fender. Plans are to shorten the length of the frame, widen the rear and get the down tube right on top of and following the front tire better.

Unlaced the 24 " wheels, going to cut 1 side off each and reattach into 1 wide rim.