Hello everyone.

Long time ago i have decided to build this bike, but now only i have put myself into situation when i can not cancel or avoid it any more

I have came up with the sketches for this bike like a year ago, but it was rough at first. But now i have connected one of the projects i am making at my school with this bike, and i have a deadline with building a frame somewhere in the middle of June. So probably this is going to be the fastest frame i have ever built Then i have quite limited time to finish the whole bike too, since in the beginning of july i am leaving to Netherlands for CSI.

Then i have quite limited time to finish the whole bike too, since in the beginning of july i am leaving to Netherlands for CSI.

This bike is inspired by older classic cruisers from 50's and 60's, and especially double straight bar 1962 Schwinn Typhoon. This would be the first bike frame i am building completely from scratch, by my own design, my first real precised tubing bending experience. I only am going to use ready-made BB, all the tubes including a head tube are just raw steel.

Anyway, here are the stages i went through already.

Here is a first sketch, i have made about march 2017:

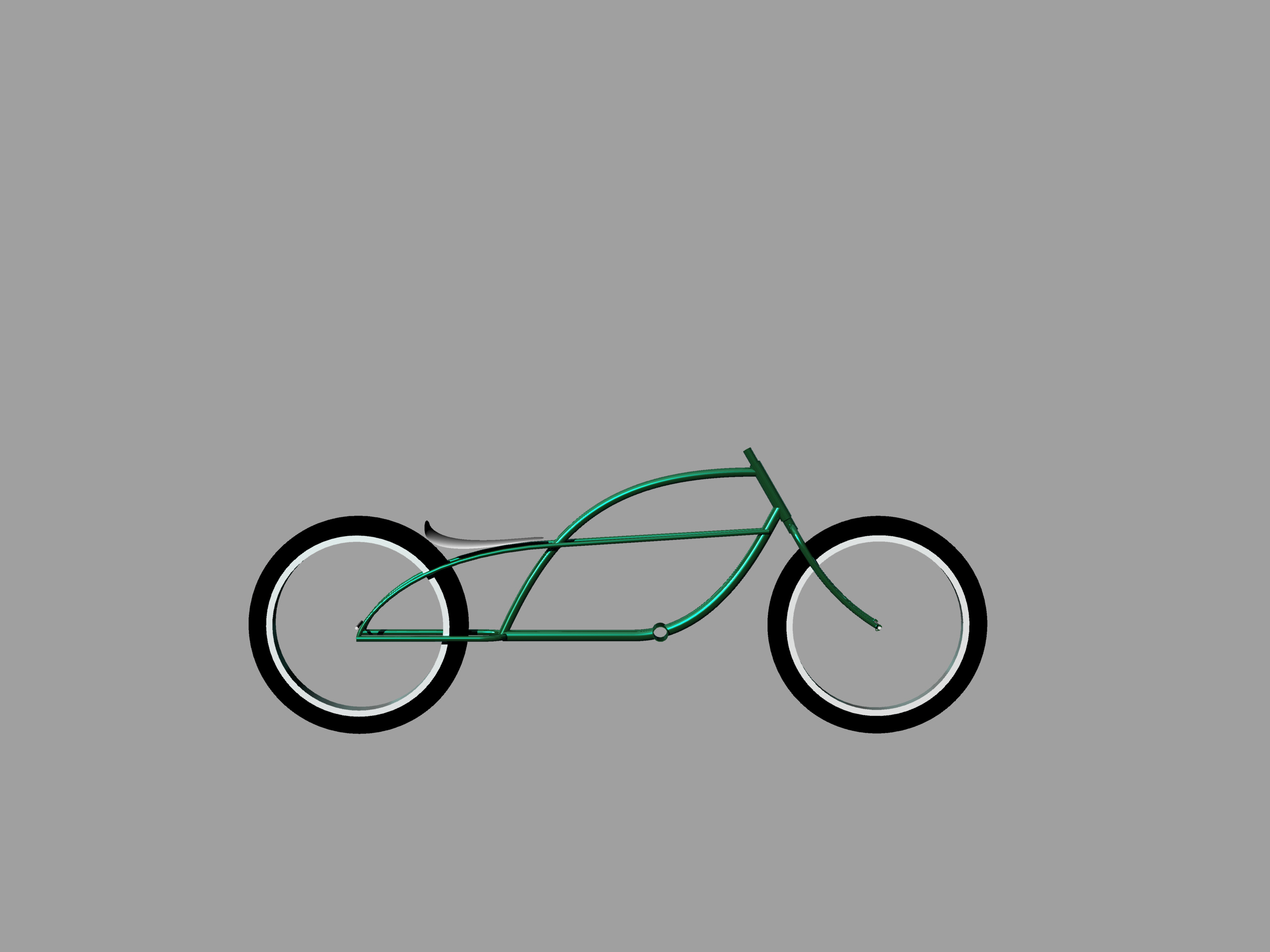

Then here is a 3d-model i have prepared, already with good dimensions and some design problems solved:

<gimme a sec, i need to reboot the computer to post the screenshots of a 3d model>

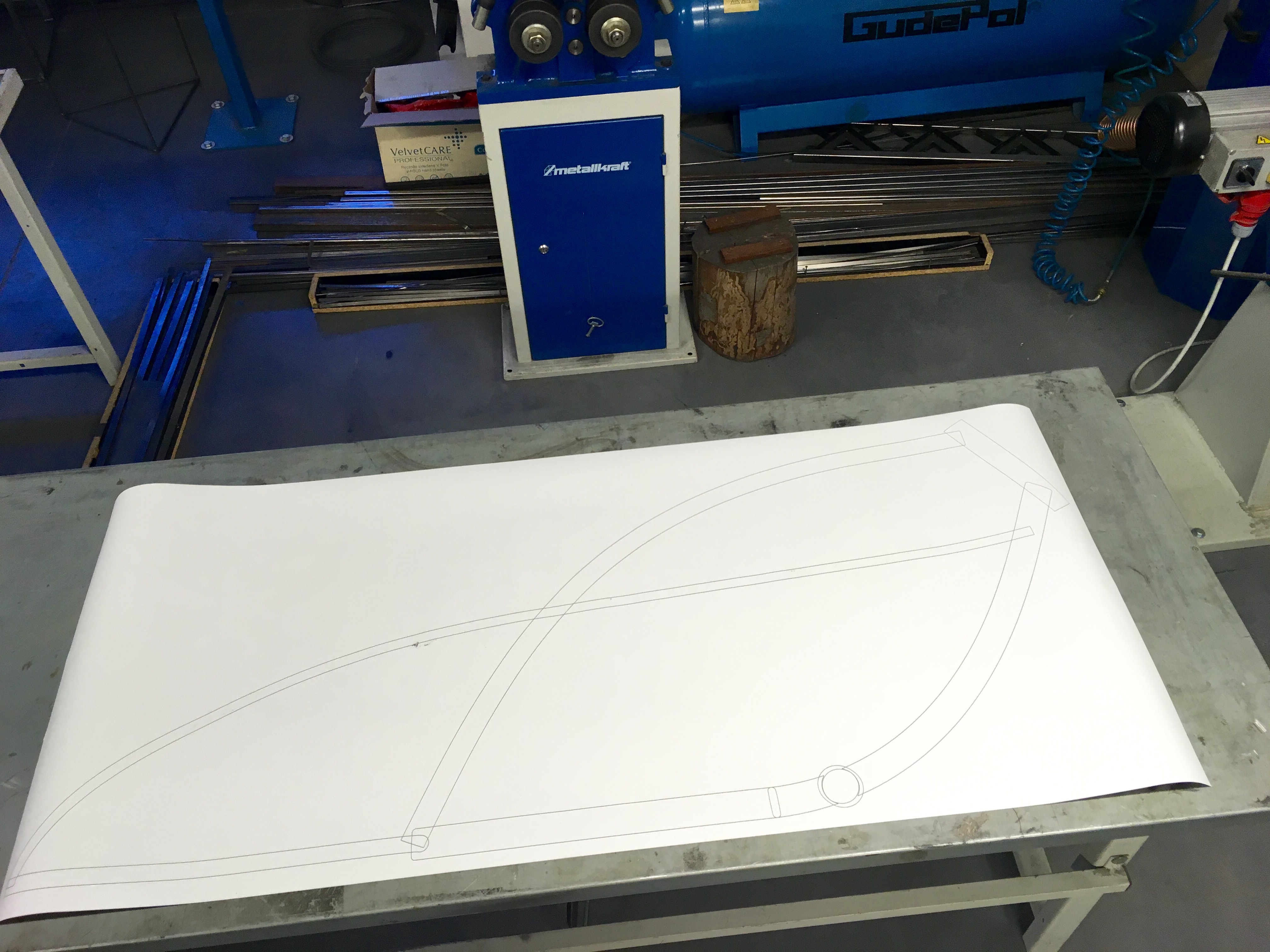

Out of that i have made a picture with all the tubes separately.

I do not have a big plotter printer to print a bike in real scale, but i have a laser cutter at school, so i have made a templates from cardboard to bend my tubing with help of it:

Some cardboard caught a fire in the process, but i had some water close by luckily

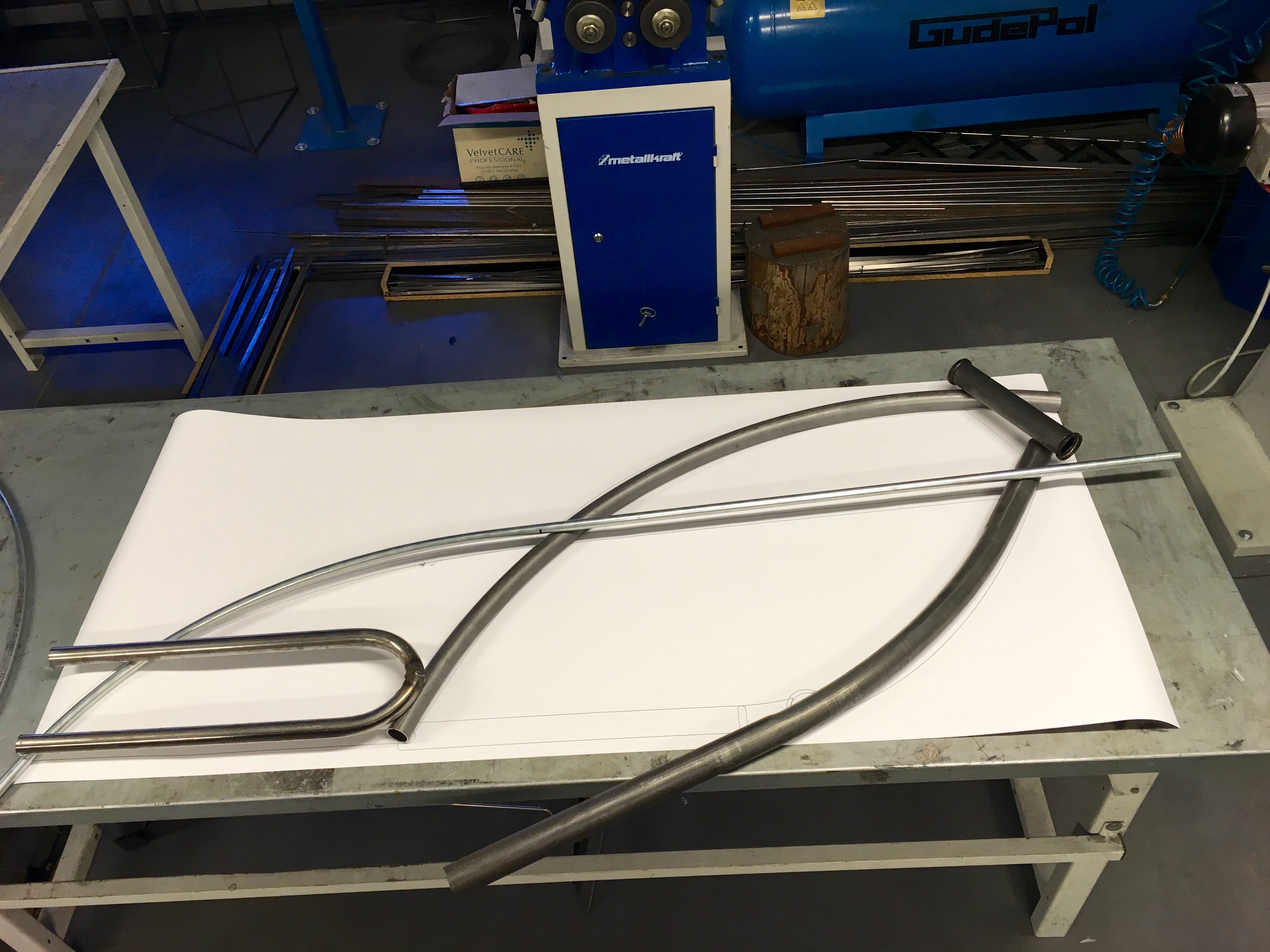

Quickly bent 1' tube, that is going to become chain stays.

Now it is time to work on a lathe, to prepare a 200mm head tube.

I had to fail two times before i have made it right Every time making a cut about 0,2mm wider then needed. Now i have two blanks for my next <200mm head tubes!

Every time making a cut about 0,2mm wider then needed. Now i have two blanks for my next <200mm head tubes!

Even though y schools lathe is not as perfect and precised as ones on youtube videos, i guess the job is done pretty neatly.

Here is a finished head tube for my bike.

Talking about the parts i am going to use, i have some ideas already. For example using the parts from 2007 Kustom Kruiser Glide i got recently. That bike got style!

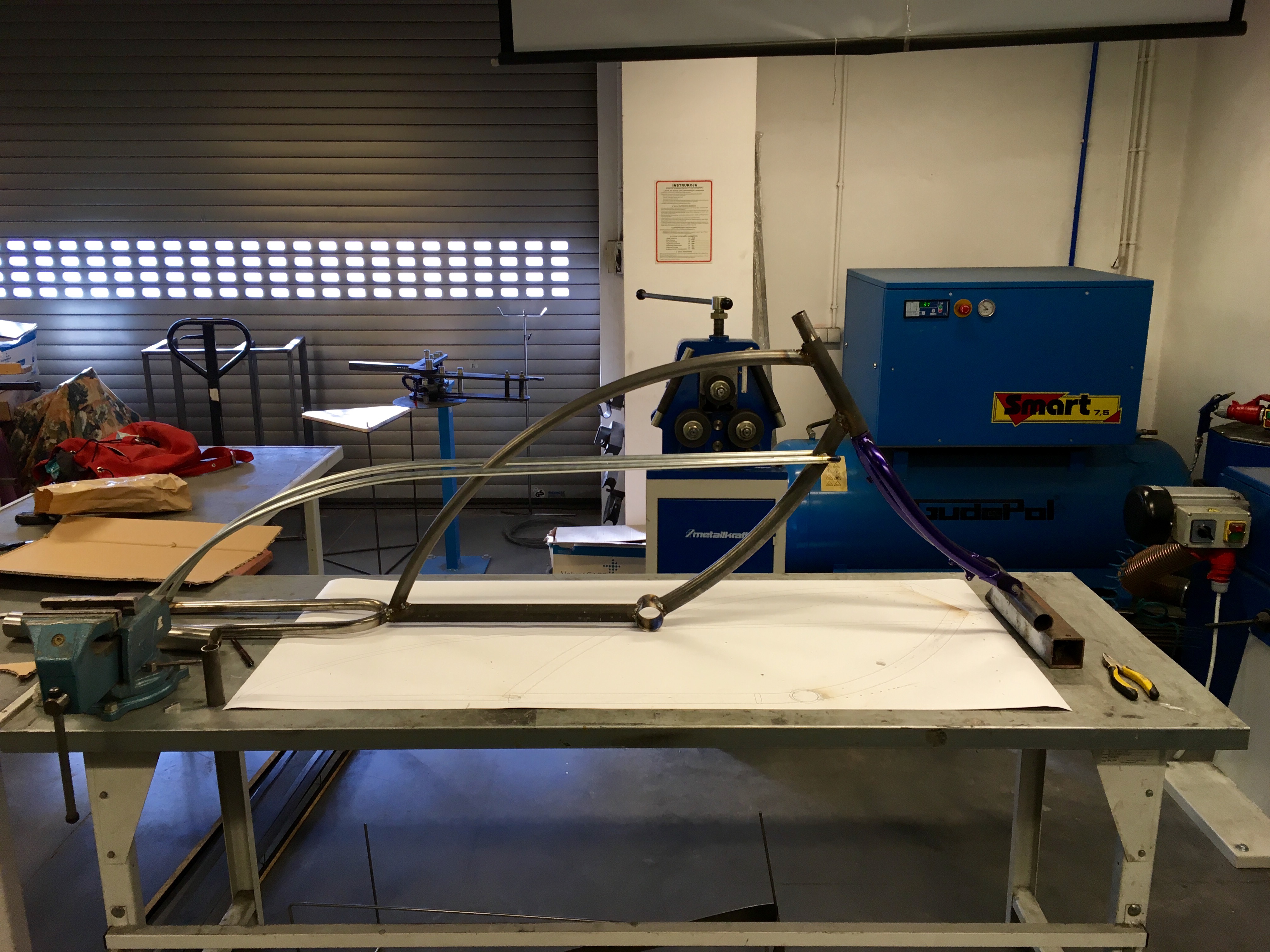

Here it is for the moment, so please wish me luck with finishing it in such a short time!

Long time ago i have decided to build this bike, but now only i have put myself into situation when i can not cancel or avoid it any more

I have came up with the sketches for this bike like a year ago, but it was rough at first. But now i have connected one of the projects i am making at my school with this bike, and i have a deadline with building a frame somewhere in the middle of June. So probably this is going to be the fastest frame i have ever built

This bike is inspired by older classic cruisers from 50's and 60's, and especially double straight bar 1962 Schwinn Typhoon. This would be the first bike frame i am building completely from scratch, by my own design, my first real precised tubing bending experience. I only am going to use ready-made BB, all the tubes including a head tube are just raw steel.

Anyway, here are the stages i went through already.

Here is a first sketch, i have made about march 2017:

Then here is a 3d-model i have prepared, already with good dimensions and some design problems solved:

<gimme a sec, i need to reboot the computer to post the screenshots of a 3d model>

Out of that i have made a picture with all the tubes separately.

I do not have a big plotter printer to print a bike in real scale, but i have a laser cutter at school, so i have made a templates from cardboard to bend my tubing with help of it:

Some cardboard caught a fire in the process, but i had some water close by luckily

Quickly bent 1' tube, that is going to become chain stays.

Now it is time to work on a lathe, to prepare a 200mm head tube.

I had to fail two times before i have made it right

Even though y schools lathe is not as perfect and precised as ones on youtube videos, i guess the job is done pretty neatly.

Here is a finished head tube for my bike.

Talking about the parts i am going to use, i have some ideas already. For example using the parts from 2007 Kustom Kruiser Glide i got recently. That bike got style!

Here it is for the moment, so please wish me luck with finishing it in such a short time!