You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tubing roller/bender

- Thread starter Uncle Stretch

- Start date

Help Support Rat Rod Bikes Bicycle Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Well, I got some tubing and started bending/rolling. I thought I would start out simple and make a single bent tube to finish a gender reassignment. I learned a few things right away. First,the machine should be firmly anchored to something. Second, make sure all of the rollers and wheels are assembled correctly or things start slipping . Third, it takes more tubing length and more force on the upper roller than I expected. I will buy a thinner wall tubing next time. I am currently using 1"x .083" x .834" I will try to post some pictures of the bike in progress.

. Third, it takes more tubing length and more force on the upper roller than I expected. I will buy a thinner wall tubing next time. I am currently using 1"x .083" x .834" I will try to post some pictures of the bike in progress.

Well when you get going good tell me whether you would buy one again. ha ha

OK so at $150 for the Harbor Freight roller who can go wrong. I'm having an issue though and looking for advice from the metal heads here. I tried some 1.5" through it, a lil muscle is all, gets a lil harder as the arc gets tighter but nothing unbearable. The only problem is it gets a swing/twist to it, I've checked the rollers to make sure they're centered and aligned but it occured both times I've practiced. Is there a trick or am I doing something wrong ? As soon as I get this right the frame is gonna be on its way to reality.

There is a bit of a trick there.... So you need to make sure when you first start that the rising leg stays plum... Gravity will want to pull the leg to one side or the other and if you don't constantly make adjustments you will wend up with a wonky ring... That has nothing to do with the bender... My fancy expensive powered machine is the same way. Once you get that twist in the ring its very hard to correct so its best if you have someone help grab the tail as it comes through and do nothing but watch and adjust the tube. What I would suggest is you make a chalk mark down the entire length of the tube using a straight edge and then line that mark up with the lip of a wheel... that way you can see which way it needs to go and how much...

$19.99

Electra Glide Wall Decal 2ft Long Sport Harley Davidson Bike Motorcylce Sticker Man Cave Garage Boys Room Decor

FatCat Wall Graphics

$412.10

$449.99

Schwinn Regioneer Womens Hybrid Comfort Bike, 26-Inch Wheels, 7 Speed, 16.5-Inch Steel Frame, Alloy Linear Brakes, White

Amazon.com

$236.22

$249.99

Schwinn Shuffle Adult Scooter, 26-Inch Front Wheel, 20-Inch Rear Wheel, Alloy Linear Pull Brakes, Steel Frame, Grey

Amazon.com

$412.30

$489.99

Schwinn Loop Adult Folding Bike for Men and Women, 20-inch Wheels, 7-Speed Drivetrain, Rear Cargo Rack, Carrying Bag, Silver

Amazon.com

Thanx monster, I appreciate the input, I had the roller on my bench but I have rails on the ends that make it difficult to keep it there once the bending start, I have mounted it to a stand, this makes it more portable and can use it outside for longer sweeps. I had contemplated trying to put some form of a guide on it to keep the tubing inline. From your advice I am taking it that the portion that is exiting the roller needs to be kept inline, does this need to be done on both sides of the roller ? It seems that once pressure is applied on the top roller, the working roller that there is little that can be done to do any further alignment. I'm going to keep practicing as I'm really wanting to get this right I have several projects in mind and a mind is a terrible thing to waste, and it just makes me go buy more projects, lol... I'm going to try and find some thinner shim washers for the working roller assembly as there is a little play in it that once pressure is applied can make the U bracket holding it move to the front or back of the roller. Thanks again and any other advice is greatly appreciated from everyone.

LOL, dude I just reread your advice the line and lip of the wheel is a GREAT idea, figure a wrench or clamp of some sort on the end might assist in moving the tubing back into alignment, possible even tack weld a piece of stock across the end to twist it into alignment, thanx once again....

I luckily haven't had this issue with my bender. I'm not really sure why either. However, Mine is really stout and there is no room for the dies to move sideways. I use .065" wall for my bikes. For the motorcycles I use .120" wall. How close is the spacing between the two outside dies....axle to axle? I have adjustment on mine, but found that it rolls better on the furthest distance. Don't know about the HF bender, but maybe they should be on the outter most holes.

How are the dies secured on the axles? May be something there too. Are you using DOM tubing or electroweld? DOM does have a tendency to twist do to the nature in which it's manufactured. Depending on the mill, you can somtimes see the spiral markings on the outside of the tubing. Electroweld tubing doesn't do this.

Monster Metal gave good advice on the marking of the tube. I do that if for nothing more than being able to realign the tube after I check for proper curvature.

If they have one of those benders at my HF I'll see about looking at it.

Hope something here may help you.

How are the dies secured on the axles? May be something there too. Are you using DOM tubing or electroweld? DOM does have a tendency to twist do to the nature in which it's manufactured. Depending on the mill, you can somtimes see the spiral markings on the outside of the tubing. Electroweld tubing doesn't do this.

Monster Metal gave good advice on the marking of the tube. I do that if for nothing more than being able to realign the tube after I check for proper curvature.

If they have one of those benders at my HF I'll see about looking at it.

Hope something here may help you.

After thinking about them..They wont bend in just one spot or will they . Can you bend a tight turn in part and something like just a curve in the other . Or does the fact that once it has a bend of any kind in it then you cant do another part because of that one?

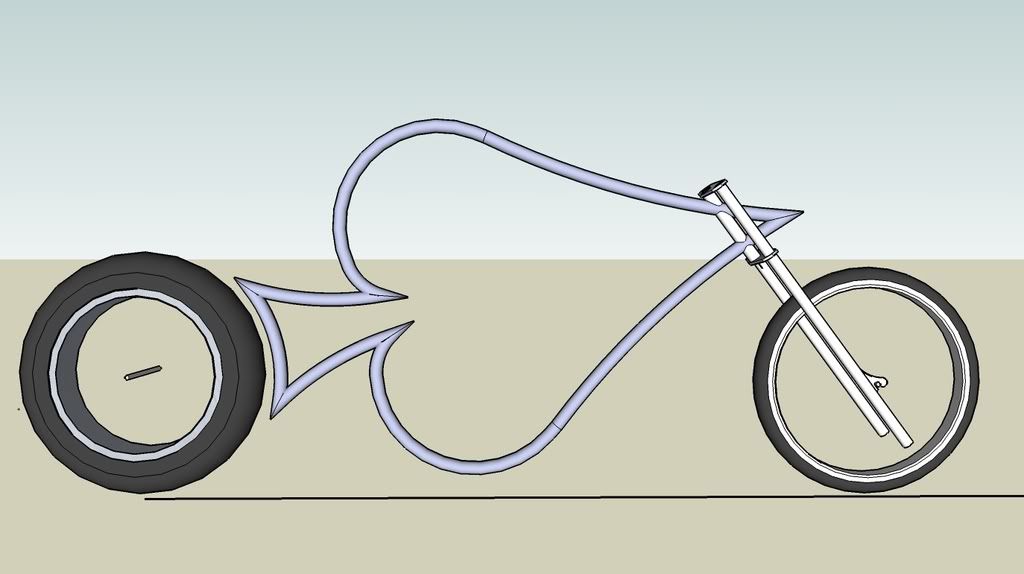

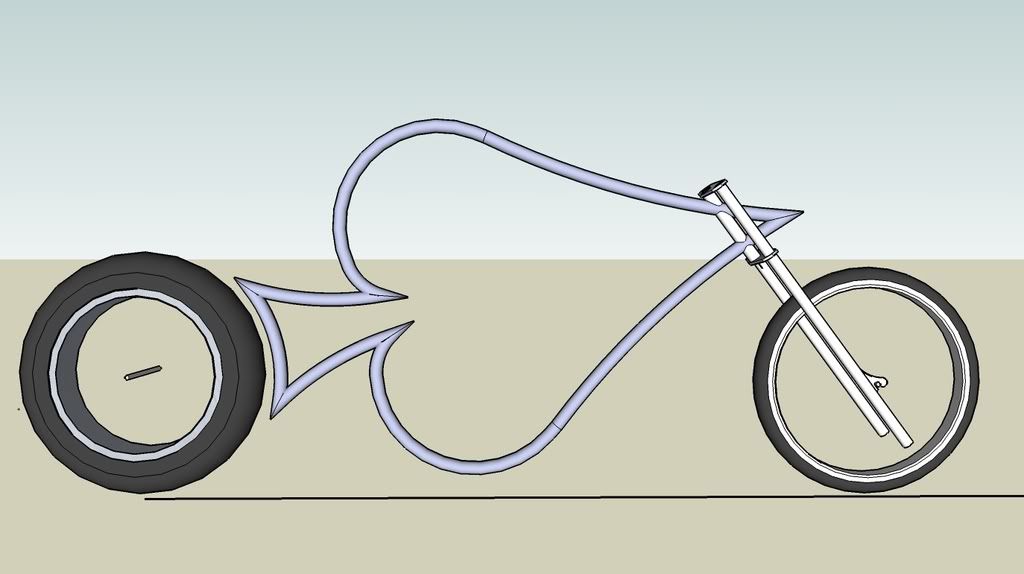

You can certainly vary the bends in the tube. It's a little tricky though. My current frame employs this technique. What I do...probably other ways too....is to measure my "actual" length on the frame that I want. Then I cut my tube at least a foot longer. Next I figure out where I want the most curve in the tube. I then put the tube in the roller and lightly roll the whole length. This starts to establish the "lesser curve" while still beginning the tighter curve. Then I go to where I want the tighter curve and start to roll that. What you need to do though, is roll a little past where the tight curve is...but loosen the roller a little. This will help blend the two curves together.

I know that explanation is probably clear as mud, hope it helps some.

I know that explanation is probably clear as mud, hope it helps some.

Yeah.... What he said.....

I usually roll two different radii and and then weld them together and blend... With a good TIG weld and blended with a dynabelter its basically one tube when your done

Here is a picture of my rolls

I usually roll two different radii and and then weld them together and blend... With a good TIG weld and blended with a dynabelter its basically one tube when your done

Here is a picture of my rolls

Ok this may be along way from this ...but could you get someone to lathe down a couple of rollers ,that were the same profile as say a common drop center rim and use the bender/roller to put them back in an original shape. like where they are bent in and out in places ? Im having to throw away alot of rims because of bends. Or because of the lip around the edge it wouldnt work.

I think that would work. I know that there was an old machine made for rolling out motorcycle fenders. I know this isn't the same as whay you're talking about, but the principle is the same. You would want your dies to be made nicely. I'm sorry I don't know what a drop center rim is or I would give you a better answer.

If you had the dies, I would guess the best way to roll the rims is to start at a place where the rim was good. Then adjust the dies so the are just snug to the rim. Then roll out the rest of the rim. This way the rim wouldn't be stretched.

If you had the dies, I would guess the best way to roll the rims is to start at a place where the rim was good. Then adjust the dies so the are just snug to the rim. Then roll out the rest of the rim. This way the rim wouldn't be stretched.

A drop center is just a rim that has the part where the spokes connect inset towards the spokes a 1/4'' or so . regular rims are flat . It seems to me if you made a male and female roller and didnt really get too tight on the adjustment and rolled a rim around it should straighten it out. It may be like bodywork and not really be that easy. :shock:

uncle stretch...try getting some 2x4's for the wheels that are 'just out of round' leave a space on the high spot and step on it enough to bring it down.....it may take a few times but unless theyre horribly tacoed itll work.

as for the bead where the tire sits try using some duck bill (the ones that look like flat bar has been welded on the ends)vice grips and just bending them to where you want them......may or may not work but if theyre going to the garbage can anyhow i dont see any harm in trying

as for the bead where the tire sits try using some duck bill (the ones that look like flat bar has been welded on the ends)vice grips and just bending them to where you want them......may or may not work but if theyre going to the garbage can anyhow i dont see any harm in trying

I had one I played with yesterday and it had three spots where it was wider than the rest. I set it on my work bench and whacked it a couple times with a rubber hammer and now it has a couple spots that are in too much :lol: :lol: :lol: It seems like there should be a better way. :shock:

The short answer is yes it would work if it was a single wall rim.... If it was a tubular or double wall no... But a single wall you could fix with a planishing hammer and a dolly (and lots of time) I have found that leverage, not wacking it has been a better answer though.. Like sensor says, a two by and a intelligent application of force will do wonders if its out of round. If its more than taco'ed then it might require some creative metalwork..