I guess this wood count as a scratch build, or at least a splinter build.

Today I started on a wooden build, kinda along the lines of a burrito. Building another burrito has always been an idea of mine, but no access to a welder put a stop to it, hence the wood.

I am a bit of a hoarder, and over the years have amassed quite a collection of useful looking bits of wood. So here goes.

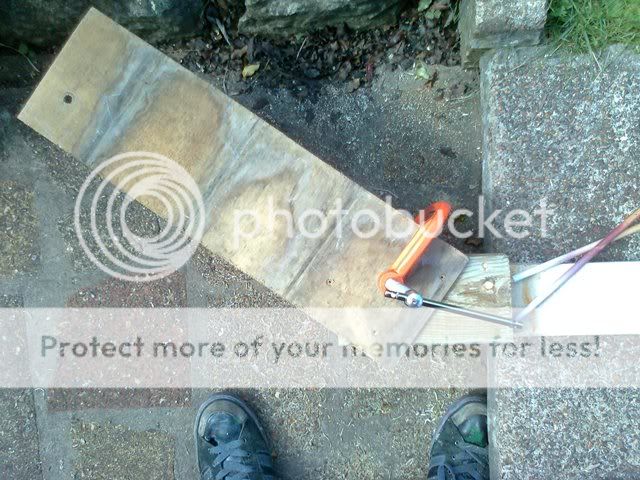

I started with a bit of wood, liberated from a pallet as the backbone. (1.5" x 3.5")

Then got some more burly bits of would and drilled diagonal holes through them (these continued into the backbone), handily the combined widths of the bits of wood bring the overall width to 135mm, the correct spacing for a mtb rear hub (almost like I planned it )

)

After the big bits were done I cut 6 dowels (points are awarded for what they are made from, they are 5/16 in diameter), these dowels are long enough to continue into the backbone through the burly bits

I glued the backbone to the burly bits and hammered the dowels through, I also glued these.

When the backbone was built I started on making the back end, for this I used 9mm ply, I drilled a 10mm hole for the 9mm axle of the rear hub to pass through and be held by the quick release, just like in a normal dropout.

The rear end will mount onto the 'burly' bits of wood, I might screw them or peg them as I did with the other bits.

Any advice would be greatly appreciated, as would a real name for the bike.

Today I started on a wooden build, kinda along the lines of a burrito. Building another burrito has always been an idea of mine, but no access to a welder put a stop to it, hence the wood.

I am a bit of a hoarder, and over the years have amassed quite a collection of useful looking bits of wood. So here goes.

I started with a bit of wood, liberated from a pallet as the backbone. (1.5" x 3.5")

Then got some more burly bits of would and drilled diagonal holes through them (these continued into the backbone), handily the combined widths of the bits of wood bring the overall width to 135mm, the correct spacing for a mtb rear hub (almost like I planned it

After the big bits were done I cut 6 dowels (points are awarded for what they are made from, they are 5/16 in diameter), these dowels are long enough to continue into the backbone through the burly bits

I glued the backbone to the burly bits and hammered the dowels through, I also glued these.

When the backbone was built I started on making the back end, for this I used 9mm ply, I drilled a 10mm hole for the 9mm axle of the rear hub to pass through and be held by the quick release, just like in a normal dropout.

The rear end will mount onto the 'burly' bits of wood, I might screw them or peg them as I did with the other bits.

Any advice would be greatly appreciated, as would a real name for the bike.