Are you using the regular or the adhesive backed sheets? Hey thanks a lot, that will help me out with a few motorcycle related FRP projects I've got planned in the future. Later Travis

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building a Fiberglass Tank

- Thread starter Rusty

- Start date

Help Support Rat Rod Bikes Bicycle Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Great work! Thanks for sharing how you do this, very inspirational!

Thanks Galt!

A little more progress. I spent some time thinking about what look I wanted. I thought about making it curvy like by straight bar Schwinn tank. I finally decided to go with the flat, boxy old school look. I have little more work to do before I glass it. I think I am going to square off the ends. I'm not liking the curves.

Cardboard dam to keep the foam from going everywhere. That is a plastic grocery bag inside just to keep it from sticking.

About six times as much foam as I needed.

The cuts are just to stress relieve the foam because the pressure of the foam expanding had warped the plates slightly.

A little more progress. I spent some time thinking about what look I wanted. I thought about making it curvy like by straight bar Schwinn tank. I finally decided to go with the flat, boxy old school look. I have little more work to do before I glass it. I think I am going to square off the ends. I'm not liking the curves.

Cardboard dam to keep the foam from going everywhere. That is a plastic grocery bag inside just to keep it from sticking.

About six times as much foam as I needed.

The cuts are just to stress relieve the foam because the pressure of the foam expanding had warped the plates slightly.

so, are the plugs underneath the foam at this stage? looks like maybe you built a cardboard dam around the plugs and shot the foam into the dam?

this is fascinating to the uninitiated. really appreciate you showing us how you do it.

this is fascinating to the uninitiated. really appreciate you showing us how you do it.

Yes, those gosh darned darns. I noticed the auto-censoring had changed that word when I was talking about my clay darns a while back. Now we also have cardboard darns and I suppose even Hoover Darn. Not to be confused with eternal darnation, mind you, which is spelled differently than the darn that holds back water. :mrgreen:

BTW, I added another picture above so you can see the plate in the bottom before I poured in the foam. I will eventually glass over the foam and these will become the plugs for the molds.

BTW, I added another picture above so you can see the plate in the bottom before I poured in the foam. I will eventually glass over the foam and these will become the plugs for the molds.

I decided I didn't like it looking so square, so I decided to chamfer the edges down. I'm liking this a lot more. :mrgreen: This 2lb foam is very easy to shape. I took the majority of it off with a Sure-Form, then finished it with a sanding block.

Just about ready to glass me thinks.

Just about ready to glass me thinks.

Thanks Hewey!

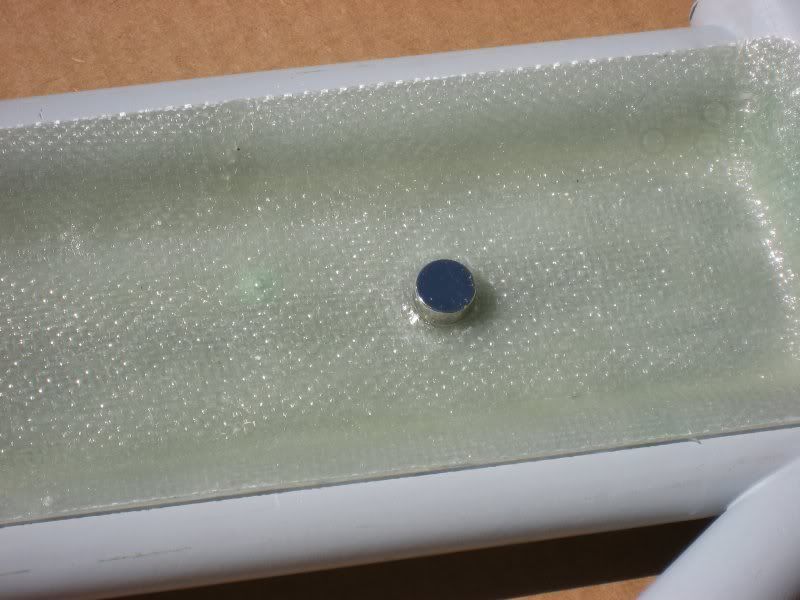

Okay, the parts have been glassed. I used one layer of 9.7oz cloth. All we need here is a hard surface that can be made smooth. It does not have to be super strong. Notice, no puddles. You want to be able to see the weave. It should look like wet cloth when finished. I have also wet out the cloth a little ways past the edge of the parts. This is so that I can zip off the excess with a razorblade after the resin has kicked, but still green (not totally hard yet).

Okay, the parts have been glassed. I used one layer of 9.7oz cloth. All we need here is a hard surface that can be made smooth. It does not have to be super strong. Notice, no puddles. You want to be able to see the weave. It should look like wet cloth when finished. I have also wet out the cloth a little ways past the edge of the parts. This is so that I can zip off the excess with a razorblade after the resin has kicked, but still green (not totally hard yet).

Looks just like the surfboards I used to make in Hawaii. Aw the smell of acetone in the morning!

Later T

Later T

Heh. Believe it or not, I actually like the smell of polyester resin. :mrgreen: It conjures up nostalgic memories of hanging out in the surf shops with my buddies as a teen – good times. The bad thing about poly is that it shrinks and tends to warp with age, so I stopped using it to build molds. Epoxy is about 3 times the cost but much nicer to work with.

Rusty said:Yes, those gosh darned darns. I noticed the auto-censoring had changed that word when I was talking about my clay darns a while back. Now we also have cardboard darns and I suppose even Hoover Darn. Not to be confused with eternal darnation, mind you, which is spelled differently than the darn that holds back water. :mrgreen:

oh, i thought you were being funny with the darns

the rounded edge on the foam looks good, BTW. is that expanding foam like the stuff that is used to fill cracks for insulation?

I worked for Local Motion Surfboards for a few years back in the 90's and shaped about 500 boards in 4 years with polyester resins. I now use 2 part Epoxy Research exclusively for surfboard construction for various reasons and bake it hard as it cures to really give it a lot more strength. I built an oven that is 12ft long that can control temp very well at around 120-150 F. I usually bake a board for 3-4 hours at 135-140F right after the epoxy has started to gel.

I build hollow wooden surfboards from 1/8" thick cedar, mahogany and bass wood planks over a fir space frame just like model airplane construction. I've made about 10 of them over the last 8 years and they surf very well. I haven't made any molds in a while but I imagine I'll use epoxy for any I will make in the future. At my last ID job I inherited a very nice 2 stage vacuum pump and bagging materials just for vacuum bagging molds. Long story how I got it but I looked up the make and model and it turns out it is designed for 100% duty cycles or continuous use for 3-4 weeks at a time. Crazy little pump has hardly ever been used and retails for over $2000. I can't wait to use it on some tank ideas I have of my own.

I actually had to quit making boards professionally back in 1994 cause I developed an allergy to acetone and polyester resins. I didn't use it for about 8 years and now I'm not so susceptible to it now but why risk it, you know.

Later T

I build hollow wooden surfboards from 1/8" thick cedar, mahogany and bass wood planks over a fir space frame just like model airplane construction. I've made about 10 of them over the last 8 years and they surf very well. I haven't made any molds in a while but I imagine I'll use epoxy for any I will make in the future. At my last ID job I inherited a very nice 2 stage vacuum pump and bagging materials just for vacuum bagging molds. Long story how I got it but I looked up the make and model and it turns out it is designed for 100% duty cycles or continuous use for 3-4 weeks at a time. Crazy little pump has hardly ever been used and retails for over $2000. I can't wait to use it on some tank ideas I have of my own.

I actually had to quit making boards professionally back in 1994 cause I developed an allergy to acetone and polyester resins. I didn't use it for about 8 years and now I'm not so susceptible to it now but why risk it, you know.

Later T

UncleKudzu,

This is a two-part foam that is mixed 50/50. You have about 45 seconds to mix it and then pour it where you want it. It expands and then sets within a few minutes. It gets nice and hard so you can shape it easily. I think the stuff that is used for insulation stays kind of flexible and rubbery (I could be wrong).

Travis,

Yeah, a number of my flying buddies have developed alergies to epoxies as well. I always tell people that just because epoxy does not have the strong fumes that polyester does, it is still not safe to breath them.

WOW! $2000 for a pump??? Nice that you didn't have to buy it.

We bag our wings as well. Here is a vacuum system that my buddy built. It is basically an air tank and a an old refridgerator pump. He welded the angle brackets onto the tank to mount the pump and then bought a few fittings and a guage. Works awesome!

This is an example of what the wings look like when they come out of the bag.

This is a two-part foam that is mixed 50/50. You have about 45 seconds to mix it and then pour it where you want it. It expands and then sets within a few minutes. It gets nice and hard so you can shape it easily. I think the stuff that is used for insulation stays kind of flexible and rubbery (I could be wrong).

Travis,

Yeah, a number of my flying buddies have developed alergies to epoxies as well. I always tell people that just because epoxy does not have the strong fumes that polyester does, it is still not safe to breath them.

WOW! $2000 for a pump??? Nice that you didn't have to buy it.

We bag our wings as well. Here is a vacuum system that my buddy built. It is basically an air tank and a an old refridgerator pump. He welded the angle brackets onto the tank to mount the pump and then bought a few fittings and a guage. Works awesome!

This is an example of what the wings look like when they come out of the bag.

How much do you charge for wings? Do you have a wire foam cutter? I have a 2-meter sailplane I designed that I'd like to have some wings made. There's a guy near Austin that does it but his prices are a bit steep. I can't get any of the Home Improvement stores in my area to get me 2" thick blue or pink foam even though they sell it in their stores up North.

Later T

Later T