Flemming: Tubesizes I used are: 25mmx1,5mm(wall thickness) for the frame, 21mmx1,5mm for the rearstays and forks, 16mmx1mm for the seatstays, 10mmx1mm for the rear rack and trussrods. Hope you'll find what you need!!

insomniacshotrods: Thank you so much!

I was somewhat surprised myself at first with how much is possible to make with just basic tools! I thought that I'd need to buy a lot more gear to make what I wanted, but once I started making simple stuff with my basic setup I realized that with some practice and some patience those tools are very versatile! Also I didn't run off and buy the most expensive tools of the sort either. I buy what I feel I can afford and if I find that it's a tool that I use a lot, then I'll upgrade when the need arises. Anyway, the way I look at it, it's not in the tools it's in the eye and the hands.

Thanks again, I'm glad to hear you like what I do!

Jeffrey: It's not june 2nd until I've finished the bike! :lol:

The bike:

Not painted but all fabrication is done...almost. I've just got to make the holder for the LEDs in the front light, and toolbags.

I'll give my brother your regards!

Here's what I've done since last time:

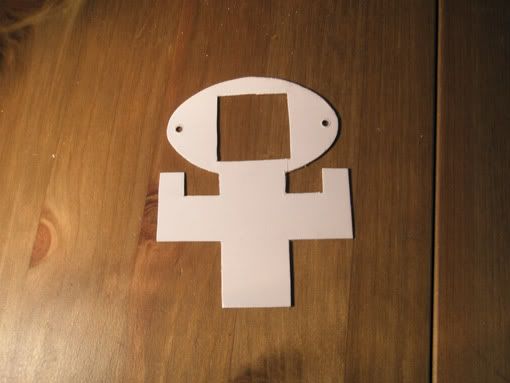

A number plate.

Shot enamel clearcoat on the sideplates.

uh...?

I'll be using these rubberthingys and run the lightcables and rearbrake wire through the frame. Did some testing on a piece of tubing before I drilled holes in the frame.

I found out that the rearbrake setup wouldn't work. The seat was to close to the brake....

...so I had to solve the problem.

Spotwelded in place. Had to minimalize every little piece to make it work!! :shock:

Phew!!

After that adventure it was too dark to keep on working outside so I headed on indoors to finish the badge.

Taped it to a tube and then taped some cardboard on top if it. Held it against the tabletop and rolled it from side to side.

Then I taped it to a smaller tube and wrapped and taped the cardboard around it and tapped it with a hammer all over.

Done!

Nicely curved!

Now the bike is taken apart and next I'll start preparing for paint. Filler time. :|