Thanks!Love that color

Heres another Penny Farthing with that color:

Thanks!Love that color

give my beautiful legs a bit more rest....

give my beautiful legs a bit more rest....

the letters and the CrMo tubes.

the letters and the CrMo tubes.

There have been some changes afoot as of late. Deleting/editing permissions have been changed. See Forum Talk thread for info...Btw: strange, I can't edit my first post and thread title anymore.

Just an update on this fiasco. Be careful if you order directly from the company. After processing my payment and confirming the order, a day later received an email saying that they would ship it once I sent them more money, as they weren't aware of the size box the bar they manufacture required. They wanted to more than triple the shipping costs.Velo Orange are very good, but supply is pretty short. I've been waiting for a set of their Tourist bars for a while

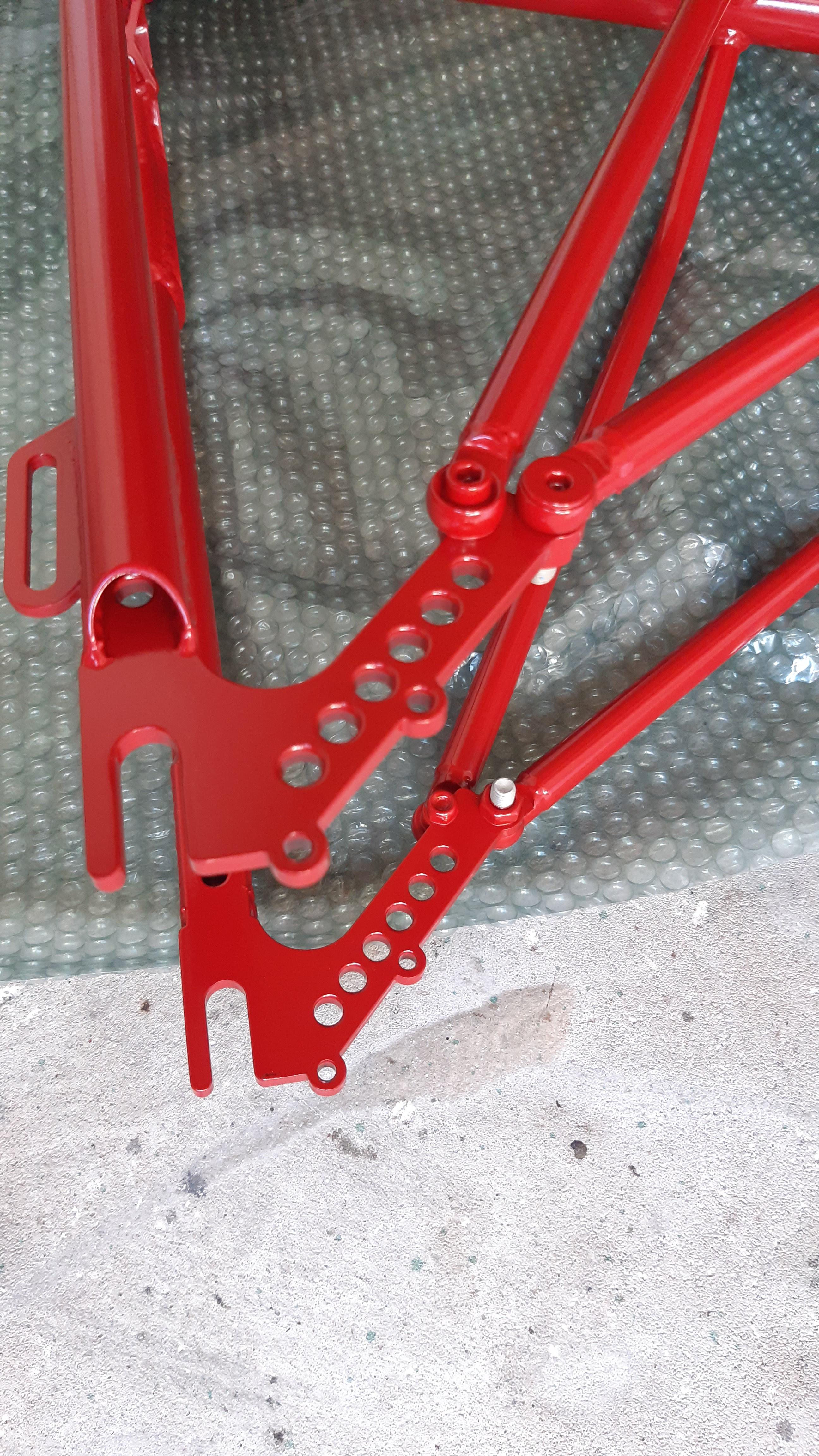

The same day I degreased it and added a layer of paint:

The same day I degreased it and added a layer of paint:

Thanks Matti,The purple is a little jarring, clashes with the red. Hub, headset, rims, stem and crank are black, I'd suggest keeping it simple, sticking to one accent color

!

!I completely understand what you mean by that... Been there!Chain audio induced irritation maintenance alarm

Enter your email address to join: