MattiThundrrr

Rattus All Terrainus

I think you use the cutter to make masks (I too am fluent in Photoshop lol). They cover up the areas where the acid won't etch. The darker areas in the badge are what's eaten away

I've heard a bit about acid-etched headbadges before, but I'm not too familiar with the process. Sounds like something I might have to try!I think you use the cutter to make masks (I too am fluent in Photoshop lol). They cover up the areas where the acid won't etch. The darker areas in the badge are what's eaten away

Yeah sorry, my badI think you use the cutter to make masks (I too am fluent in Photoshop lol). They cover up the areas where the acid won't etch. The darker areas in the badge are what's eaten away

I used iron-3-chloride for brass because when I tried with electricity like with aluminum it just wouldn't work well (I'm to lazy to find out why or to buy equipment)I've heard a bit about acid-etched headbadges before, but I'm not too familiar with the process. Sounds like something I might have to try!

I really ought to get a vinyl cutter... between this and using vinyl masks to paint graphics on bikes, I could get some serious mileage out of one.Yeah sorry, my bad

You can make stencils with the vinyl cutter.

View attachment 287816

View attachment 287815

You can also paint your graphics or use electric tape and then cut by hand with a scalpel but that's much more time consuming...

Then you just need some destilled water, vinegar and salt, some wires and an old power supply and you're good to go. I played a little with concentrations, voltage and time but it is fun and not that hard. There are also many videos on how to do it. Aluminum is a good metal to start.

I used iron-3-chloride for brass because when I tried with electricity like with aluminum it just wouldn't work well (I'm to lazy to find out why or to buy equipment)

Edit:

For drawing I use sketch book from autodesk for android. It's free and works just fine even on smartphones. You can import and export your drawings quite easily and the software of the cutter can work with the .png.

I'm old, have lots of tools, but I'm still learning. Looks like I'm going to get another saw to hang out with my coping saws. Tighter turns, I like that!fretsaw

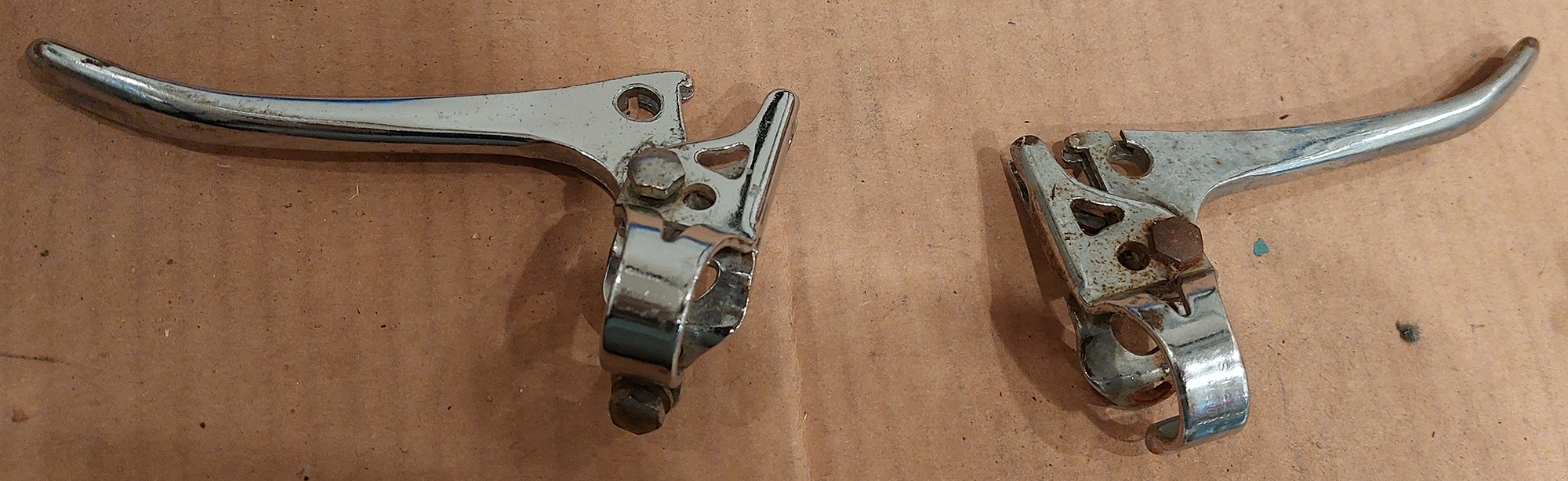

Take pictures and note the order as you remove pieces. Keep the parts removed in the order you took them off, put them back in reverse order

Pretty comprehensive rebuild of a crusty shimano unit, but modern compared to your stuff, so there may be more here than you have to deal with

Thank you! I've heard of folks using cinnamon before, but nutmeg and cloves I wasn't aware of. I'm trying to avoid the BLO/clear coat over rust look, as I want this to look natural. The tricky part is I want the blue paint to look glossy, but the "rust" needs to look flat and dry. Maybe I could get away with a flat or satin clear, but I don't know.NOICE!!!!!

I've used nutmeg, cinnamon and ground clove to get different rust shades and clearcoated over to look like BLO on rust.

Thank you! Flat clear might work, but if not, I can just run the parts as they are and worry about it later. If anyone's got a good idea on sealing fauxtina, it'd be either @OddJob or @The Renaissance Man.Great job on the faux-tina!! Not sure on sealing it. Maybe dead flat clear spray paint? @OddJob might have some good ideas for this.

I typically don't like using clear coats. But sometimes it can be the only good option. Other options would be things like BLO or polishing compound/wax. Or stopping while you're ahead.Thank you! Flat clear might work, but if not, I can just run the parts as they are and worry about it later. If anyone's got a good idea on sealing fauxtina, it'd be either @OddJob or @The Renaissance Man.