You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

"BLACKJACK" MiniVelo FatBike BUILD. (New owner, new progress soon!)

- Thread starter LukeTheJoker

- Start date

Help Support Rat Rod Bikes Bicycle Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Been thinking more on that, so I finally weighed the wheels and tires, they came to 5.9kg each. (13lbs) How does that compare to a set of Mongoose beast or dolomite wheels?Those are going to be some heavy wheels though...

Luke.

Last edited:

Pic update for page 5:

Finalised plan:

Forks:

Wheel hub adapters:

Started on the frame loops:

Bottom bracket and cranks:

Next step will be the other half of the frame.

Luke.

Finalised plan:

Forks:

Wheel hub adapters:

Started on the frame loops:

Bottom bracket and cranks:

Next step will be the other half of the frame.

Luke.

Nice work . glad to see progress. I understand the cold short days stink (can't do cold well myself as I have so much nerve damage in my right arm & hand)

This was in response to post 87 when it was post 86 and this was post 87.

This was in response to post 87 when it was post 86 and this was post 87.

Last edited:

$151.20

$189.99

RoyalBaby Freestyle Kids Bike Boys Girls 18 Inch BMX Childrens Bicycle with Kickstand for Ages 5-8 years, Green

Amazon.com

Desperate times call for desperate measures!

After many days of being too cold to work, and having to wait till 3 in the afternoon for the temps to even reach double digits (if it does at all) and then the sun goes down at 4:30, time I factor in set up and pack up, I have no incentive to work, so as I said, desperate time call for desperate measures!

I put on thermal underwear under my work overalls and set up a fire to try and offset the freezing breeze a bit and today I made some good progress at last!

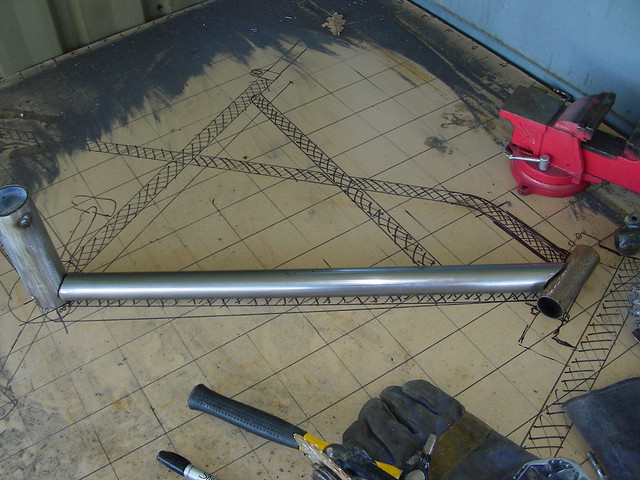

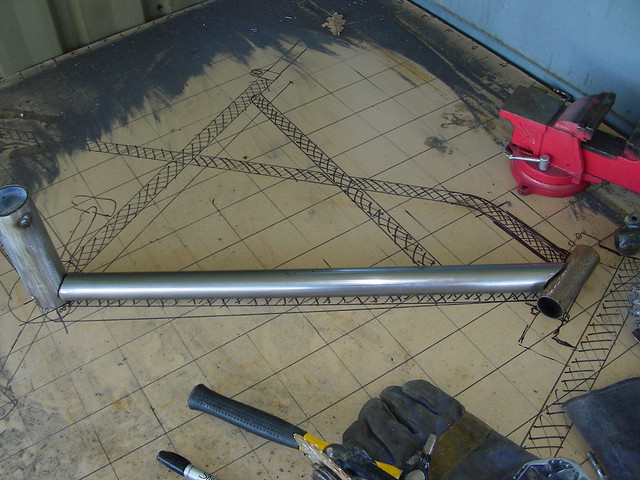

Started with cutting the tubes for the main frame section:

As you can see, I have yet to find somewhere to buy seat tube tubing from, so I still have to cut and drill and sleeve and weld to get decent lengths:

The advantage of building the bike the way I am, I can just prop each different diameter of tube to the right height with various washers, it works well and ensures all the tubes are centred without multiple checking:

8mm washer stack for the top tube, 3mm for the seat tube (5/16 and 1/8):

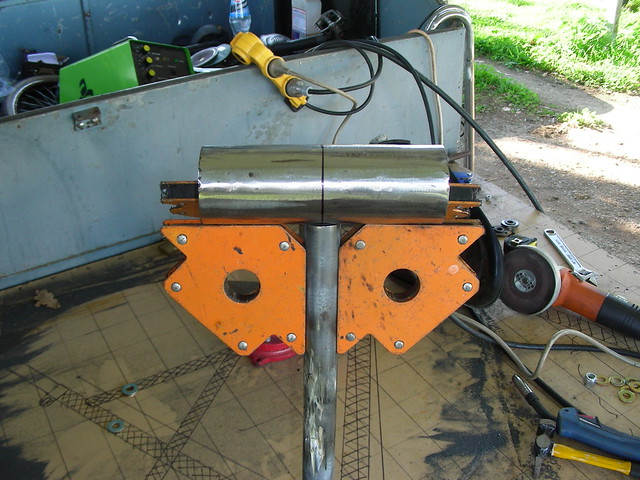

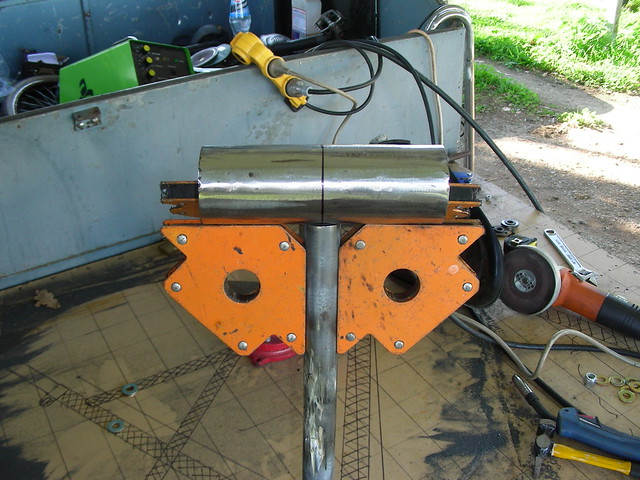

Here is how I made sure the bottom bracket ended up straight and level, first marked a centreline and then placed 4x90 degree magnet clamps in place:

And here it is all tacked up:

After the welding was finished I took the tape measure to it and it was only out less than 0.5mm from level end to end (20 thou", not anywhere near enough to worry about!) and dead straight! Very happy!

Then moved on to (yes, I told you it was a good productive day, not finished yet!) the frame dropouts, no fancy tools in my kit to do these, just 4mm plate (1/6") and an angle grinder with a cut off disc:

Tacked them together and cleaned them up with the grinder, then on to the non-drive side and welded on the threaded boss that the axle will thread into:

Bad pic, but this shows the two dropouts fitted to the rear wheel with the correct length axle spacers in place:

Here is them set up with a temporary spacer tube ready for welding to the rear loops next time.

Next time should be good, join it all together in to one cool frame!

Luke.

After many days of being too cold to work, and having to wait till 3 in the afternoon for the temps to even reach double digits (if it does at all) and then the sun goes down at 4:30, time I factor in set up and pack up, I have no incentive to work, so as I said, desperate time call for desperate measures!

I put on thermal underwear under my work overalls and set up a fire to try and offset the freezing breeze a bit and today I made some good progress at last!

Started with cutting the tubes for the main frame section:

As you can see, I have yet to find somewhere to buy seat tube tubing from, so I still have to cut and drill and sleeve and weld to get decent lengths:

The advantage of building the bike the way I am, I can just prop each different diameter of tube to the right height with various washers, it works well and ensures all the tubes are centred without multiple checking:

8mm washer stack for the top tube, 3mm for the seat tube (5/16 and 1/8):

Here is how I made sure the bottom bracket ended up straight and level, first marked a centreline and then placed 4x90 degree magnet clamps in place:

And here it is all tacked up:

After the welding was finished I took the tape measure to it and it was only out less than 0.5mm from level end to end (20 thou", not anywhere near enough to worry about!) and dead straight! Very happy!

Then moved on to (yes, I told you it was a good productive day, not finished yet!) the frame dropouts, no fancy tools in my kit to do these, just 4mm plate (1/6") and an angle grinder with a cut off disc:

Tacked them together and cleaned them up with the grinder, then on to the non-drive side and welded on the threaded boss that the axle will thread into:

Bad pic, but this shows the two dropouts fitted to the rear wheel with the correct length axle spacers in place:

Here is them set up with a temporary spacer tube ready for welding to the rear loops next time.

Next time should be good, join it all together in to one cool frame!

Luke.

Understand that WFT! Sorry about the post issue, I had a pic problem and just deleted the old post and put it all in a new post, turned out you commented in the meantime!Nice work . glad to see progress. I understand the cold short days stink (can't do cold well myself as I have so much nerve damage in my right arm & hand)

Luke.

Its all good. I needed a good laugh. Now the post I made is a bit weird lol but made a confusing note to it to make it more or less confusingUnderstand that WFT! Sorry about the post issue, I had a pic problem and just deleted the old post and put it all in a new post, turned out you commented in the meantime!

Luke.

Forgot to mention, with the extra work I did getting the adapters in nice and tight to the rear wheel, the rear dropouts are now set at 250mm (10") instead of the 300mm (12") I was expecting to need. Happy about that!

Luke.

Luke.

Sorry, no progress this last week, health has been off, and did some work on the Joker build, have to keep moving on it before the deadline. Should have this frame all welded up soon though!

Luke.

Luke.

You can doo it!

At least you can once the health improves!

This is interesting in a few ways as I grabbed the wheels of a dirt bike a while back as a way of getting the fatter rims for the wheelchair. Did not work there but as you are showing there may be another use for them. Good to see how much you are getting done on this build as well as Bonine.

At least you can once the health improves!

This is interesting in a few ways as I grabbed the wheels of a dirt bike a while back as a way of getting the fatter rims for the wheelchair. Did not work there but as you are showing there may be another use for them. Good to see how much you are getting done on this build as well as Bonine.

Been trying to get out there and weld this frame together, it is so annoying to be this close to a completed frame and have to wait so long to see it!

Here is a taste of our weather at the moment, we are too close to sea level for snow, but the frost gives it a good effort:

Hopefully progress soon!

the grips I ordered for this bike arrived today, but they sent the wrong ones, they sent me ones without the flange, so emailed them and hopefully they will fix it up for me...

Luke.

Here is a taste of our weather at the moment, we are too close to sea level for snow, but the frost gives it a good effort:

Hopefully progress soon!

the grips I ordered for this bike arrived today, but they sent the wrong ones, they sent me ones without the flange, so emailed them and hopefully they will fix it up for me...

Luke.

I decided on a new name for the build, going to call it "BLACKJACK" for a couple of reasons...

It will be black...

It runs 21" tires...

Seems appropriate...

Luke.

It will be black...

It runs 21" tires...

Seems appropriate...

Luke.

This is going to be a Mini worth watching!! I've always liked minivelos and folding bikes. No adult looks right on them but they are fun to ride.

I LIKE BIKES

I LIKE BIKES

They do look a bit weird, but I think that might be half the reason I love them!This is going to be a Mini worth watching!! I've always liked minivelos and folding bikes. No adult looks right on them but they are fun to ride.

I LIKE BIKES

Update on the grips, turns out the pic on the website was wrong, so they are refunding my money and I can keep the grips they sent, so no harm-no foul... They have always been good.

Now to try and find some grips that are 1: Long-140mm+-, 2: Lock on, 3:Flanged...

Luke.

Depends where you are, Australia is a big country and we are well down south...Guess I'm geographically challenged, I've never thought of it being "cold" down under. Frost on the tires my wake up call.

Luke.