MattiThundrrr

Rattus All Terrainus

Is anyone else having problems seeing BRE's pictures lately? I just get broken link after broken link. And a broken heart. Could it be imgur related?

Is anyone else having problems seeing BRE's pictures lately? I just get broken link after broken link. And a broken heart. Could it be imgur related?

View attachment 178252

If struggling to decide between TIG welding and soldering - try TIG brazing then, could be a perfect technique for you

Brazing is technically soldering as well, so i am just referring to it in the same words as Bart. I am guessing he actually meant brazing when he wrote he was going to solder the fork crowns.Do you mean TIG welding and soldering, or TIG welding and brazing?

Very true, but only as far as TIG also being an arc welding process, technicallyBrazing is technically soldering as well,

I can see them all no issues

Some corporate are wired to block imgur, Tumblr, etc.......Thanks for looking, Cap. I'm thinking it's a me issue, can see em at home, problem occurs when using work wifi

Great easy solution! Cool to see how you make progress on your projectThat TIG brazing is gorgeous @Captain Awesome . That would look beautiful polished with a clear coat. The video is nice aswell. The guy jokes around and can laugh about his mistakes!

I emailed a company that could help me with fillet brazing the fork. I only have acces to MIG welding. For other welding/soldering stuff I need a pro.

This company in the north of the Netherlands is also a framebuilder, so enough experience there.

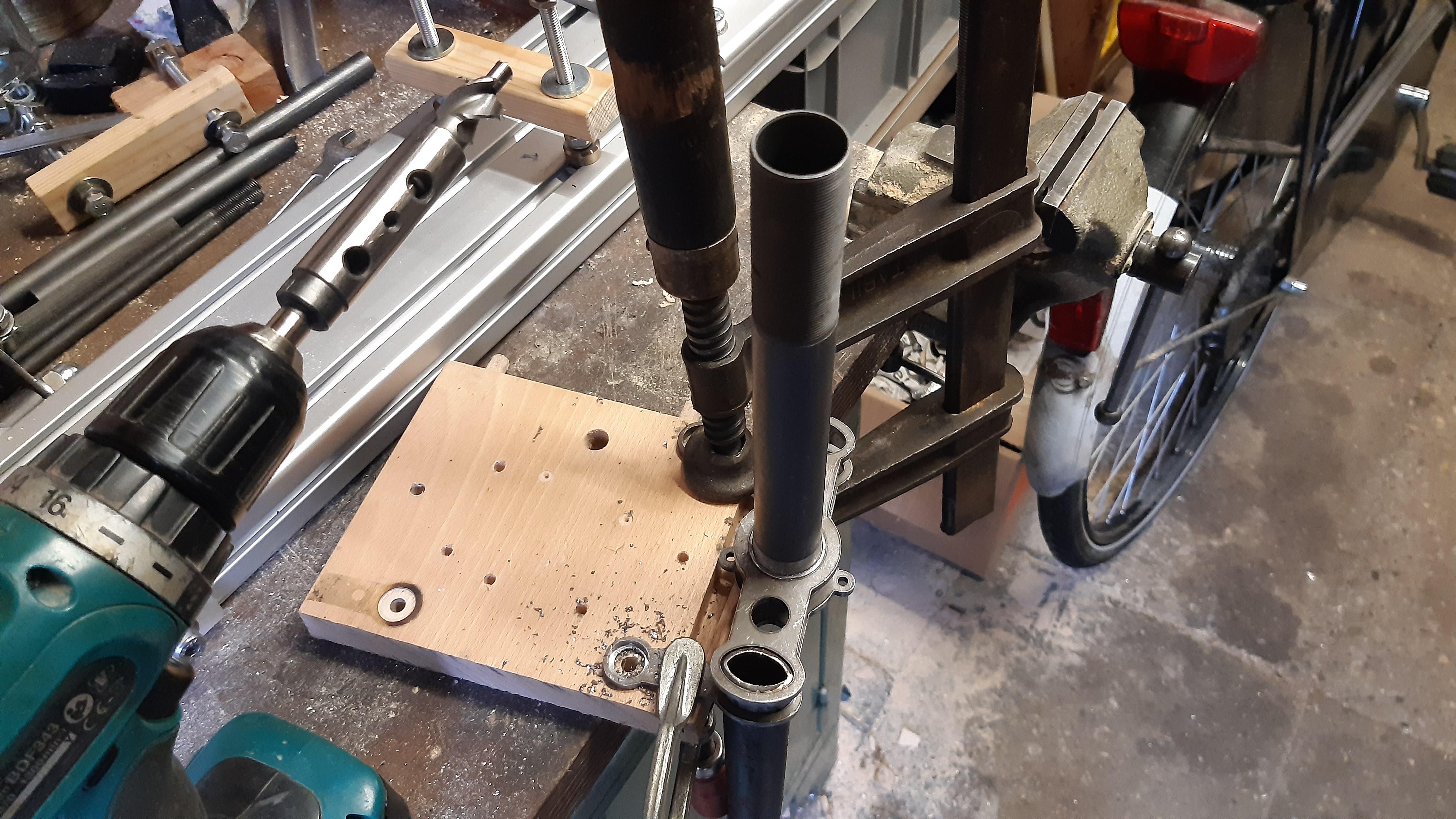

I made some alterations to the welding JIG. Now its all aligned perfectly!

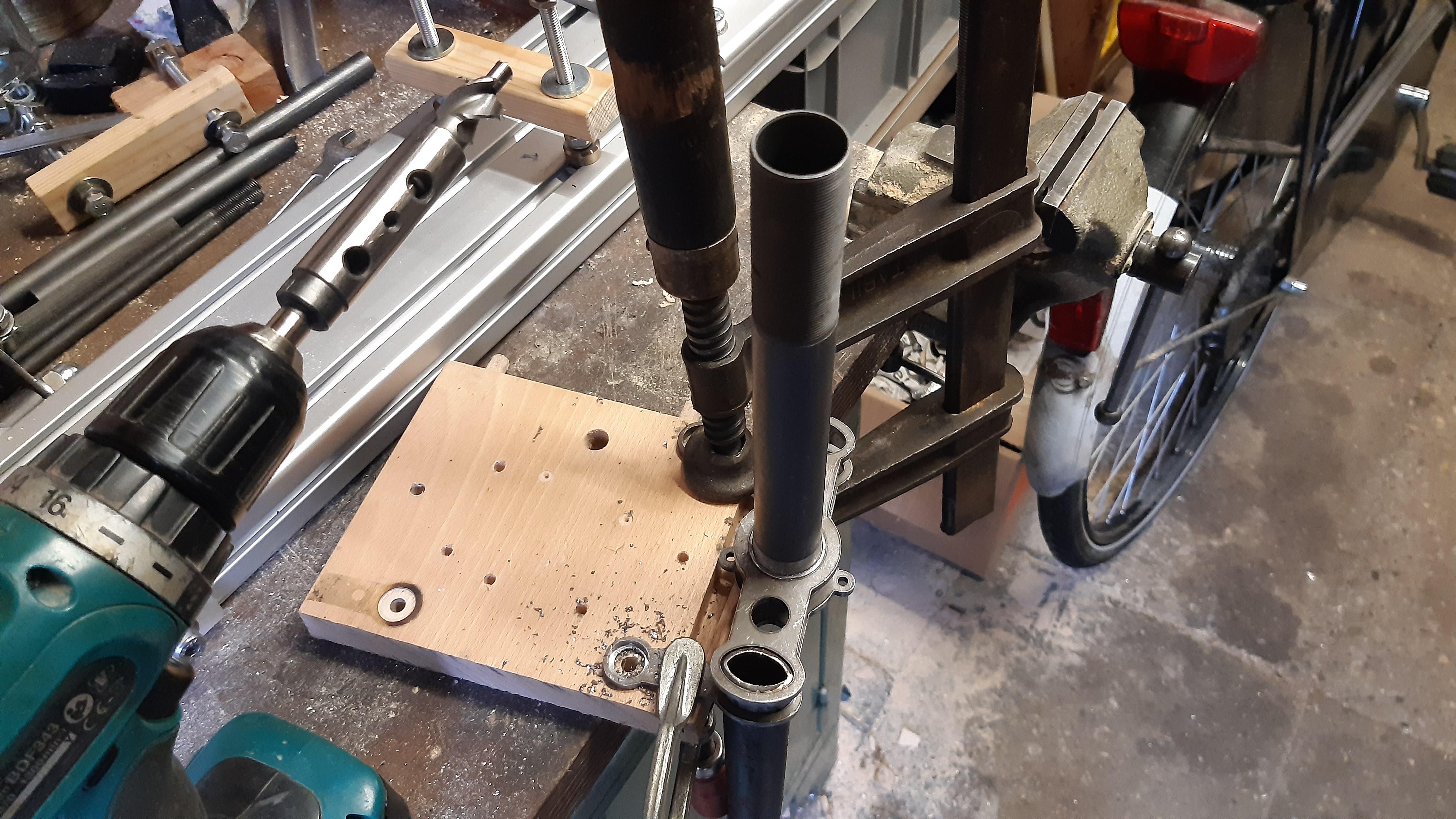

OK, how did you make M10 thread in that 20mm tube??? I used a wedge bolt/anchor bolt. Its the same principle like an old bicycle stem really. This is how I did it:

Anchor/wedge bolt in the tube, clamped and ready to cut/saw that hook.

Original Anchor/wedge bolt.

This one is perfectly the size of the inner tube! Only thing I needed to fix: The small wedge (between the plates) also is a M10 thread, but its not locked, so it could get lost.

Therefore I slightly damaged the threads and used loctite 601 locking agent on there.

Now I can tighten and loosen the top nut endlessly without fear of losing the tiny wedge nut in there.

Thank you Frankie! Maybe I'll cycle to your shop one day, we can share bicycle stories etceteraGreat easy solution! Cool to see how you make progress on your project

Thank you Frankie! Maybe I'll cycle to your shop one day, we can share bicycle stories etcetera

Do you have anything new in the works? As mentioned before, I do not have the time right now to fully read this forum...

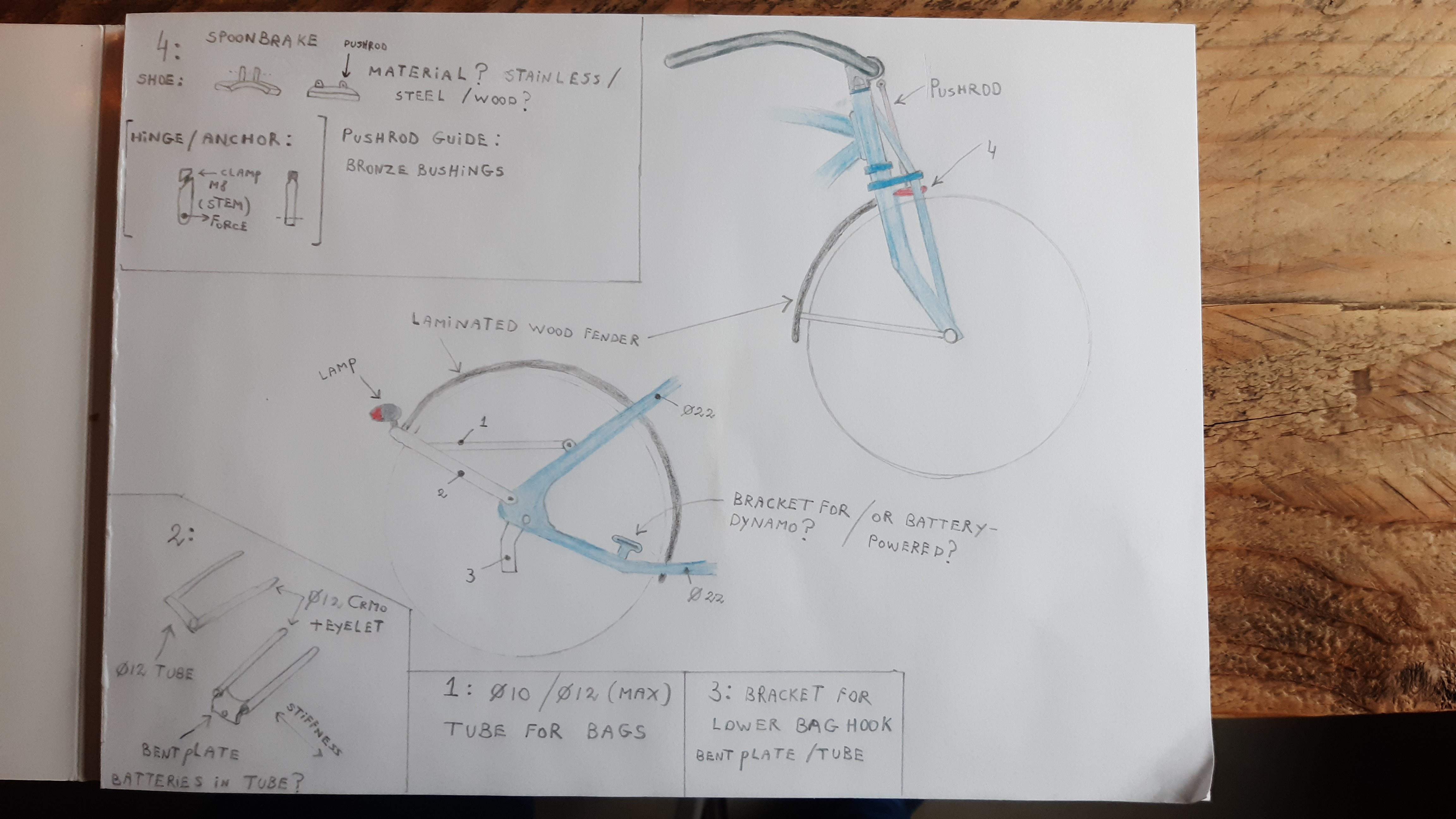

Build updates: (see the pictures and the comments underneath)

For ease of assembly and welding, I drilled the 'truss holes' to the 15mm tube size. Still I am not using a full length tube. Not necessary for this fork, even though it is stronger. I work with what I have around my shed.

A good view on the how to. This type of drill does not self-center, so I used a piece of wood to clamp it and align it.

Succes!

A person told me they could'nt notch the angle (lowest part, near the fork dropout). So I measured, I took the hacksaw and file and notched it within an hour.

I am very happy with the results!

The frame came in!!! Very happy right now!

I do not dislike that lasercut logo, but I don't know if it fits the look I am going for. We'll see!

I managed to scramble some old lamps from a second hand website! These are very nice!!

Yep, makes sense to me!I made a quick mockup to get a sense of the bike.

I think you and I have the same idea...Just an idea, now that I can see the whole thing, how about losing the exhaust bracket and having a steel tube-like spacer. So you have the top headset nut, the steel tabbed washer on top of that, the spacer tube to run through your top bracket, and then the top nut tightening down on that? The tube spacer would be long enough and just snug enough on the top bracket to allow bearing adjustment without chaffing/rattling? Or sleeve the outside of the steel spacer tube with a nylon bush?

My design will certainly need some compliance up at the top because I will be tying together two forks, one with suspension:

I would love to see a sketch of that.I think you and I have the same idea...

Yes they are. Haha thanks!Awesome! Are those bakfiets rims? So sick!

Thanks for the tip mate!

Thanks for the tip mate!