This is one method for building a sheetmetal tank. It requires using a welder (mine is mig) and basic tools such as a body hammer and dolly, clamps, grinders, tin snips etc.

Start with making a pattern... as you can see I made the pattern 1/4" small all they way around, which should leave a 1/8" gap when finished since the sheetmetal will take up the other 1/8"

Transfer the pattern to some 2x material and cut it out with a scrollsaw...

Since the tank I am making is going to be fairly thick, I cut two blanks then clamped them together and sanded them to match... keep in mind, the tank will only be as good as the buck you build it over.

Then rounded off the edges to make a left and right side...

I also added a block on the backside of each half so that I could clamp it in the vise...

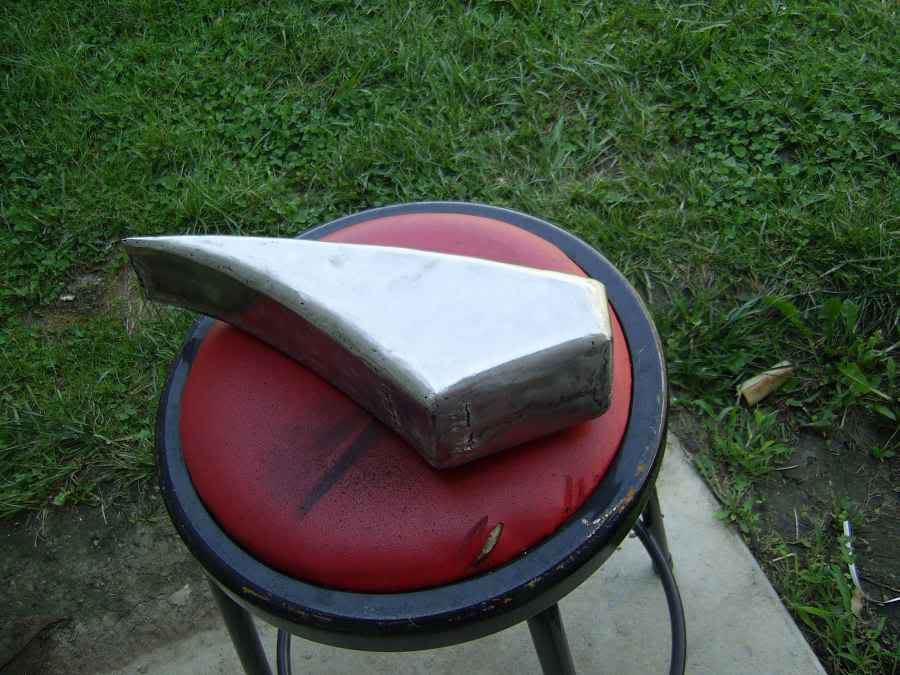

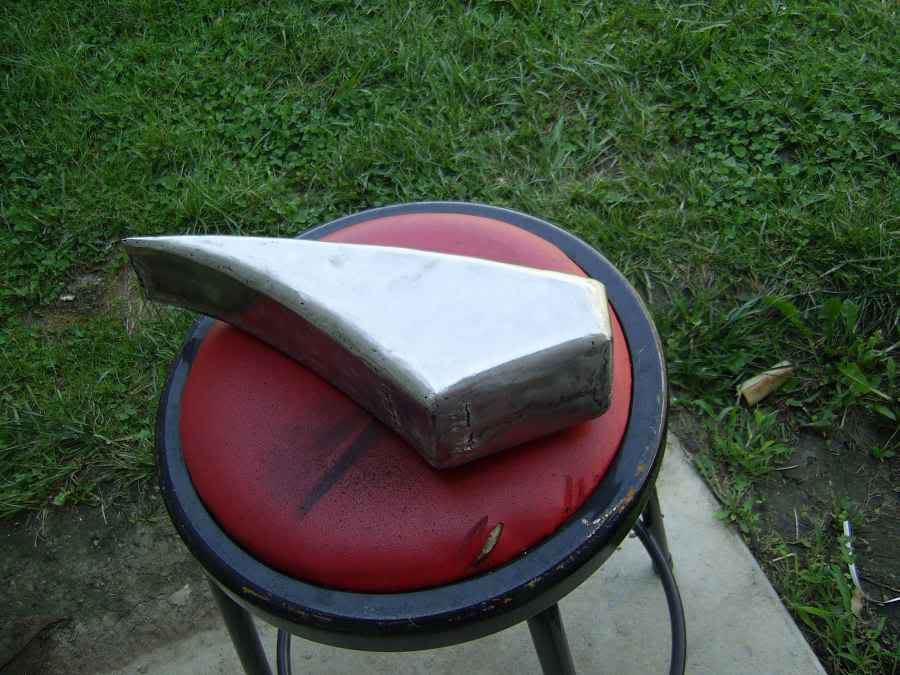

So now that the forms are done, Its just a matter of clamping the metal over the form, hammering... cutting and welding, trimming, whatever it takes to get it to lay down and match the form. This is where a shrinker/stretcher machine would have come in handy.

So at this point I have the right side panel completed, now go back and make a left side, then join the two with a strip of sheetmetal to get the width you want.

And this is what it looks like on the bike...

And here is a shot with it all smoothed up and painted...

Start with making a pattern... as you can see I made the pattern 1/4" small all they way around, which should leave a 1/8" gap when finished since the sheetmetal will take up the other 1/8"

Transfer the pattern to some 2x material and cut it out with a scrollsaw...

Since the tank I am making is going to be fairly thick, I cut two blanks then clamped them together and sanded them to match... keep in mind, the tank will only be as good as the buck you build it over.

Then rounded off the edges to make a left and right side...

I also added a block on the backside of each half so that I could clamp it in the vise...

So now that the forms are done, Its just a matter of clamping the metal over the form, hammering... cutting and welding, trimming, whatever it takes to get it to lay down and match the form. This is where a shrinker/stretcher machine would have come in handy.

So at this point I have the right side panel completed, now go back and make a left side, then join the two with a strip of sheetmetal to get the width you want.

And this is what it looks like on the bike...

And here is a shot with it all smoothed up and painted...