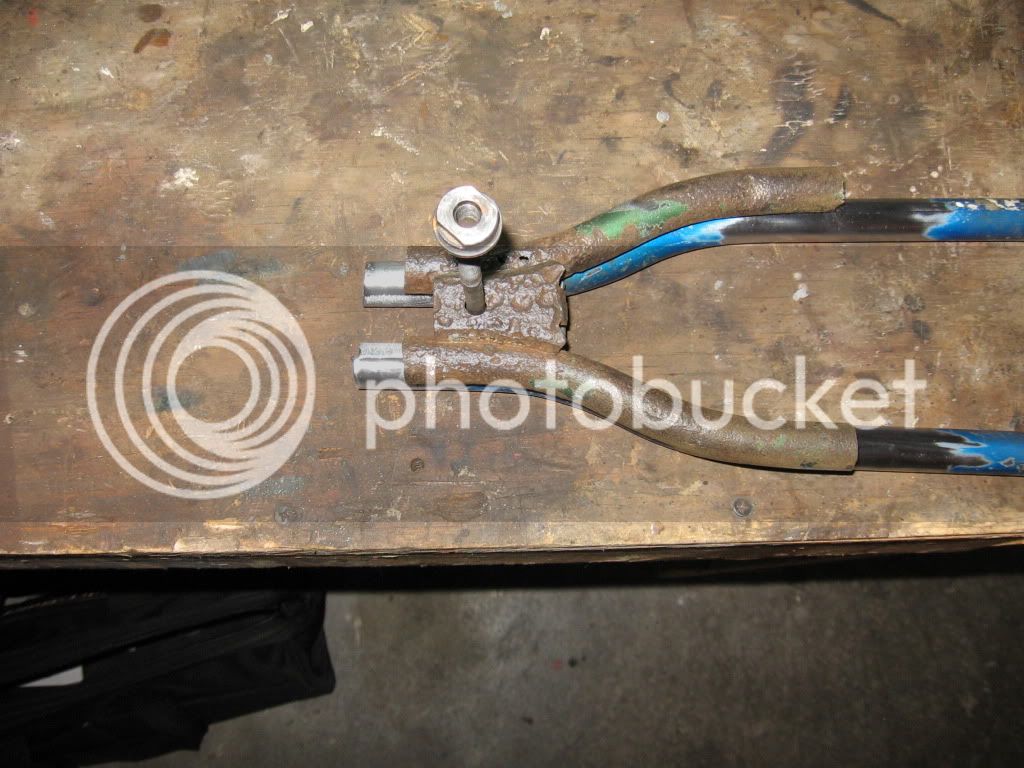

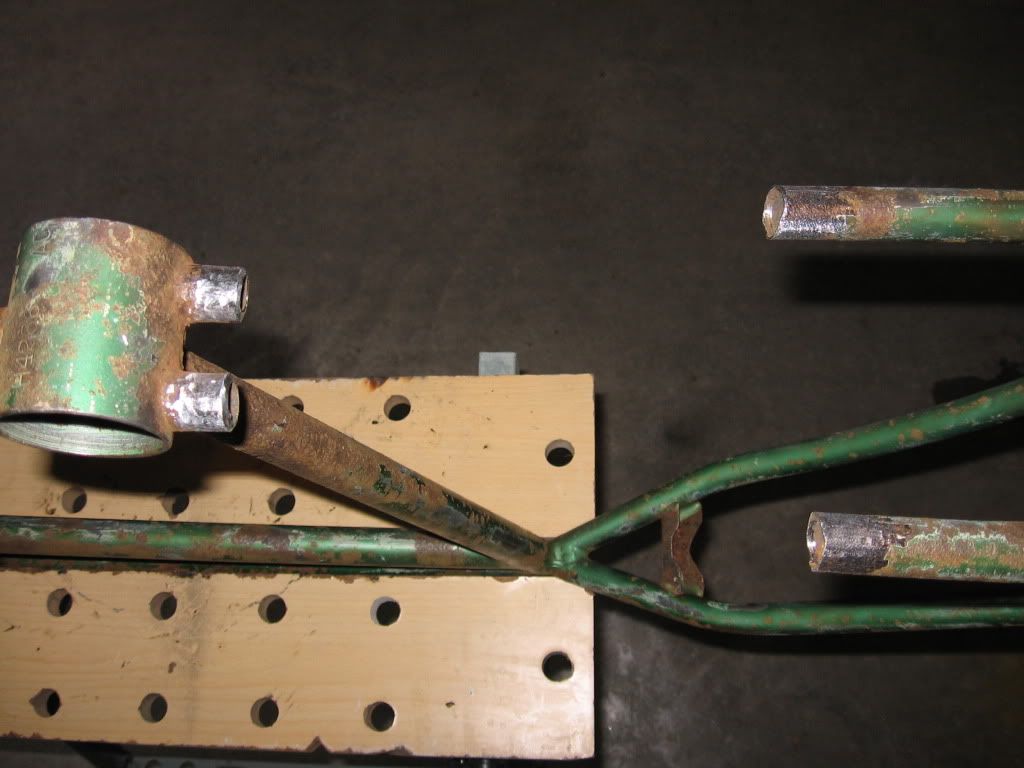

Here is the frame section replacement pictorial.

1. The kickstand mount is identical. The chainstays on the girls frame are flat while the boys kicks up at the rear. Still the tubing diameter is the same and the section that needs replaced is not dependent on the difference in styles.

1. The kickstand mount is identical. The chainstays on the girls frame are flat while the boys kicks up at the rear. Still the tubing diameter is the same and the section that needs replaced is not dependent on the difference in styles.