Those that have followed my builds before know I always start with the wheels, and I always lace the wheels with fresh spokes because I want them to look new, and I like the way the custom spokes work to finish the "correctness" of the wheel build.

For my front wheel I went with a 22 x 1-3/8" rim to keep the difference between the sizes proportional to what an original 20/16" Slingshot was. The downside is that the only 22" rim I could find was alloy. And it was powder coated. It was too dissimilar to the steel chrome rim I had for the back, so I had a LOT of work to do on it.

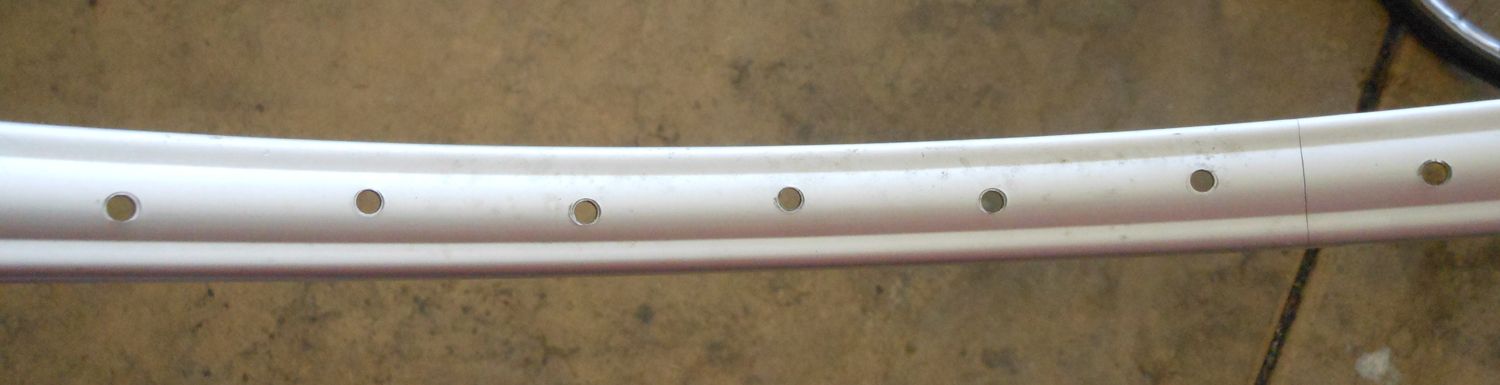

Here is the rim I got for the back. It had some corrosion issues and needed new life brought back to it.

The front rim took me literally a couple weeks to complete. Not solid, but when I could steal time to work on stuff, sanding that rim is what kept me busy. I used a wire wheel to attack the powder coat, and it worked, but it left gouges and texture in the rim that I had to sand down with progressively finer sand paper. After that I had to polish it a couple times to get it to closely match the chrome of the rear rim.

The rear rim I had to beat back the corrosion, then polish the hell out of it. Here are the results, completed this afternoon.

Front rim.

Rear rim inside (That's primer I paint in there to keep them from corroding again.)

With that all done, it's time to lace!

Before:

After:

Then I tension, dish and true the wheels. The alloy wheel was a treat because steel wheels just don't true like an alloy one will. That front is super smooth. The rear is well done as well, of course, because I'm awesome.

And then some sneakers.

All your Huffy pics you've been posting have really inspired me to do something with this Huffy I got from Rob.

All your Huffy pics you've been posting have really inspired me to do something with this Huffy I got from Rob. All your Huffy pics you've been posting have really inspired me to do something with this Huffy I got from Rob.

All your Huffy pics you've been posting have really inspired me to do something with this Huffy I got from Rob.