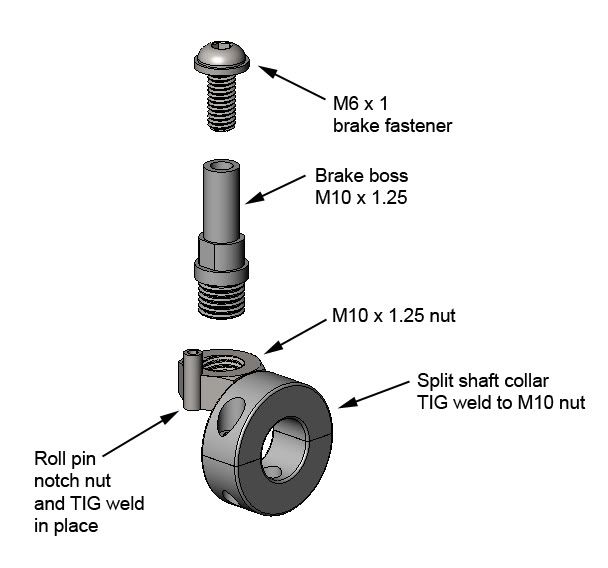

2manybikes said:Do you have any concerns about high stresses in the seat stay tubing at the section where the collars are attached? You might experience some local buckling effects in the area where the clamping forces are concentrated. Probably won't be an issue on a heavy cruiser bike with thick ductile steel tubing but it might cause problems with something lighter.Dowie Soetenga said:Those split shaft collars have a high tortional and axial load rating as well. For a 1/2" - 9/16" I.D. split shaft collar the clamp rating is 1,400 lbs to either rotate the clamp or move it along it's axis by .010". So one clamp per brake lever is an estimated 2,800 lbs of compression force they can withstand before twisting. In other words, I'm thinking this is more than enough for the force that these brakes see at the pivot junction.

Ask me how I know :roll:

I completely agree. I would only use this design on thick wall steel frame tubing. My 63 Schwinn frame has a typical wall thickness of .080". Also, the shaft collar I.D. has to match the tubing diameter to equally distribute the clamp force.