I am rat-rodding a 57 Western Flyer (see link below for the story so far...)

http://www.ratrodbikes.com/forum/viewtopic.php?f=21&t=38164&p=373148&hilit=vonfink#p373148.

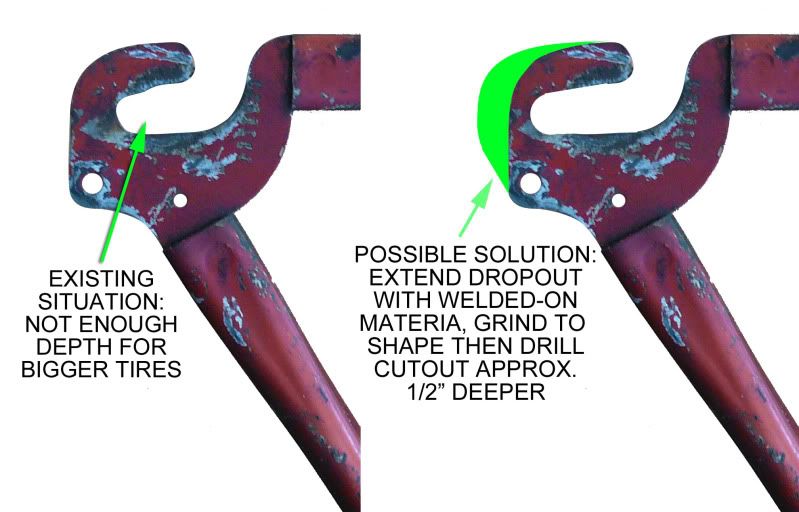

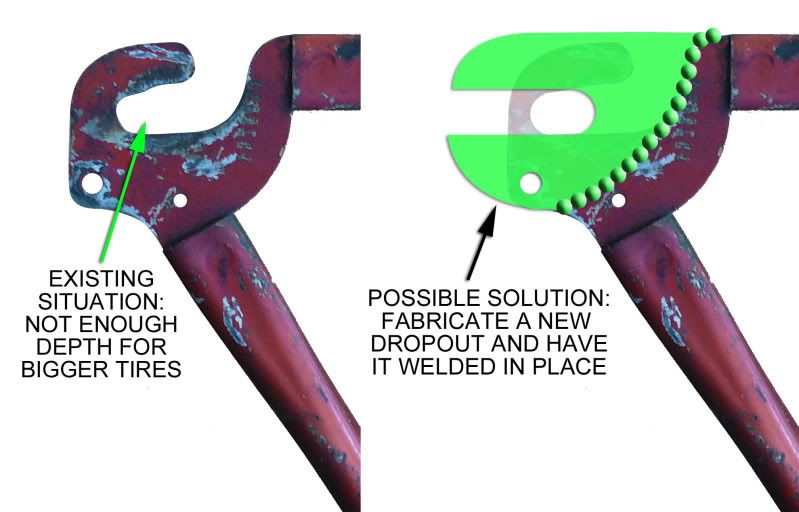

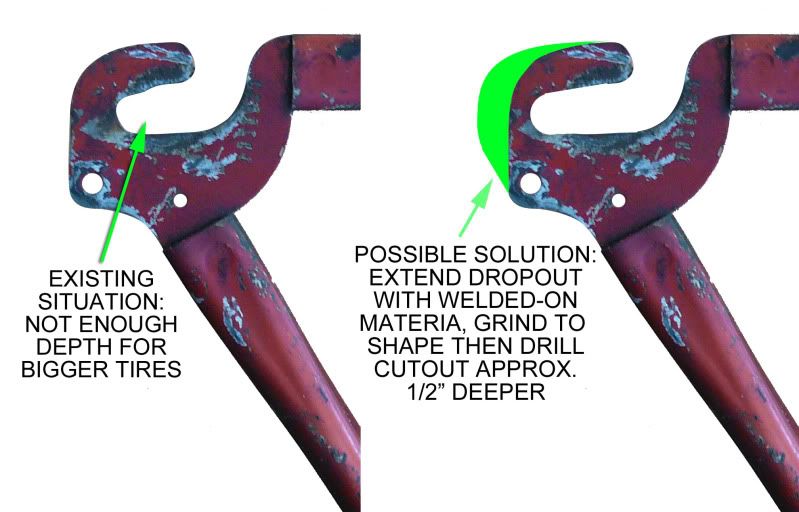

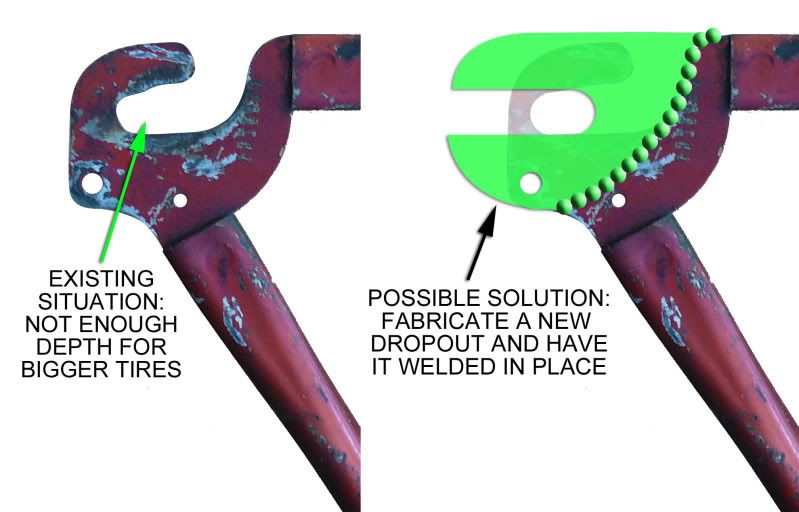

Upon having some new wheels built (a nexus 3-spd rear Workman rim and a drum brake front) and mounted with new tires, I am running out of tire clearance. This is by diameter more than width, because the new tires are fitting high and fat on my wheels. I like the fat tire appearance so I am willing to make adjustments. In the front it means I will sacrifice my fender as there is just not enough clearance. In the back it is not so simple. I think I am going to need to adjust the dropouts in order to give me more room to move the wheel back. Here are my thoughts below:

So...which will work best? If I go for either, I am guessing I'll need to hand-fabricate the added material (thinking drill, jigsaw and grinder), have a welding shop weld it in, and then grind away the beads? I could use some advice here because I have never done anything like this.

Thanks,

Tim

http://www.ratrodbikes.com/forum/viewtopic.php?f=21&t=38164&p=373148&hilit=vonfink#p373148.

Upon having some new wheels built (a nexus 3-spd rear Workman rim and a drum brake front) and mounted with new tires, I am running out of tire clearance. This is by diameter more than width, because the new tires are fitting high and fat on my wheels. I like the fat tire appearance so I am willing to make adjustments. In the front it means I will sacrifice my fender as there is just not enough clearance. In the back it is not so simple. I think I am going to need to adjust the dropouts in order to give me more room to move the wheel back. Here are my thoughts below:

So...which will work best? If I go for either, I am guessing I'll need to hand-fabricate the added material (thinking drill, jigsaw and grinder), have a welding shop weld it in, and then grind away the beads? I could use some advice here because I have never done anything like this.

Thanks,

Tim