Three years after my first velocar building attempt I want something new.

As the old one it has to be a 2+2 seater to be used as a family cruiser.

While my old Retroadster has a steel frame, a rather heavy birch ply bodywork and weights 85kg, the new one has to be significantly lighter.

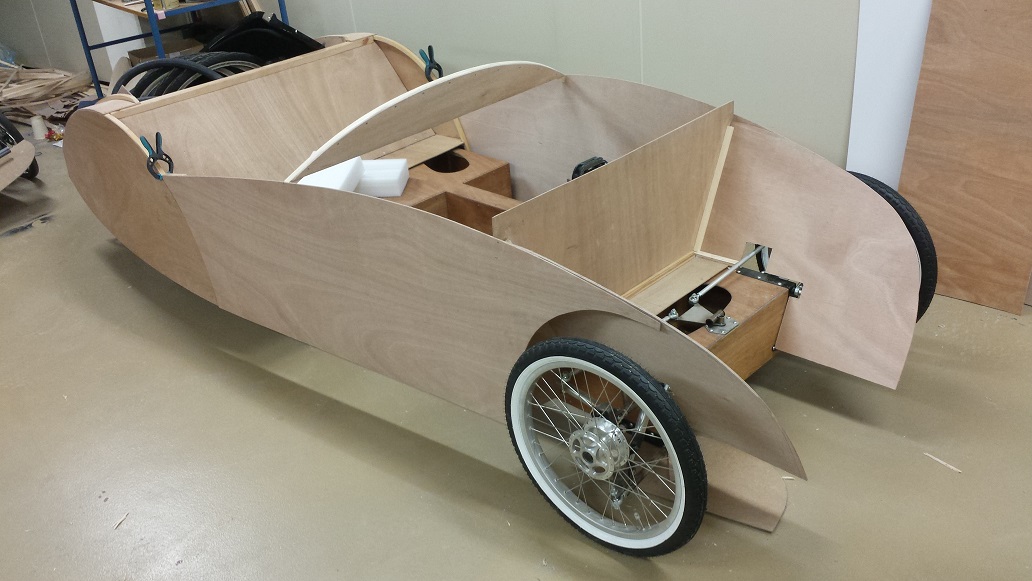

After excessive weight-vs-costs calculations of all possible materials I came to the conclusion to use gaboon plywood for the frame and body.

It's very light, much lighter than birch or even pine, it's relatively cheap, rot resistant and I can order it at my local wood store.

The weight target for the new velocar is around 65kg.

For the naked frame I calculated 15kg.

I began over the winter, cutted out all the plywood pieces.

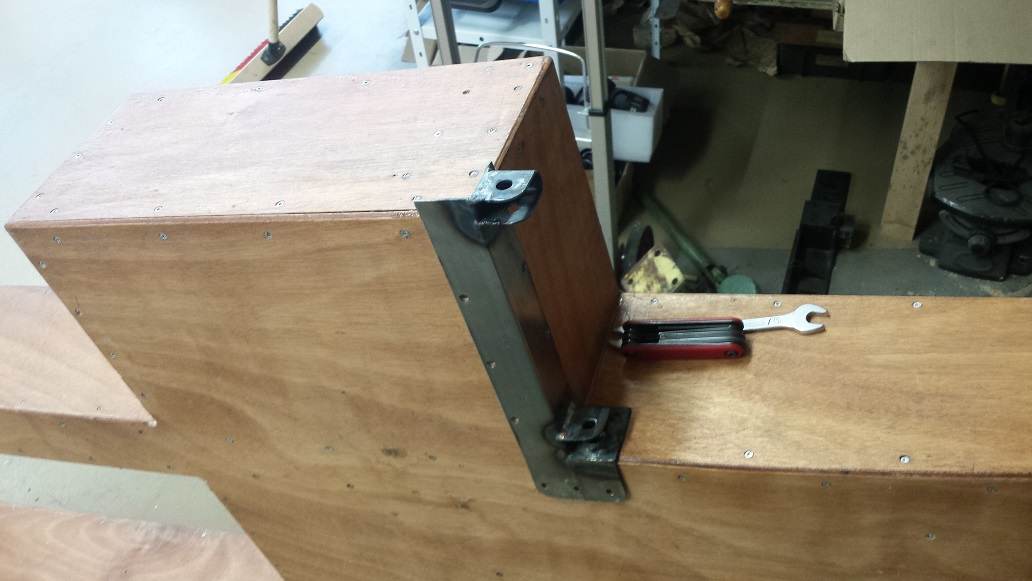

For proper strength the plywood is reinforced with 20x20mm spruce stringers.

The whole construction is close to an old wooden airplane.

Now the frame nears completion.

I have to say, it's the most complicated and critical part of the velocar, because structurally most important.

If the frame breaks, all other parts are worthless.

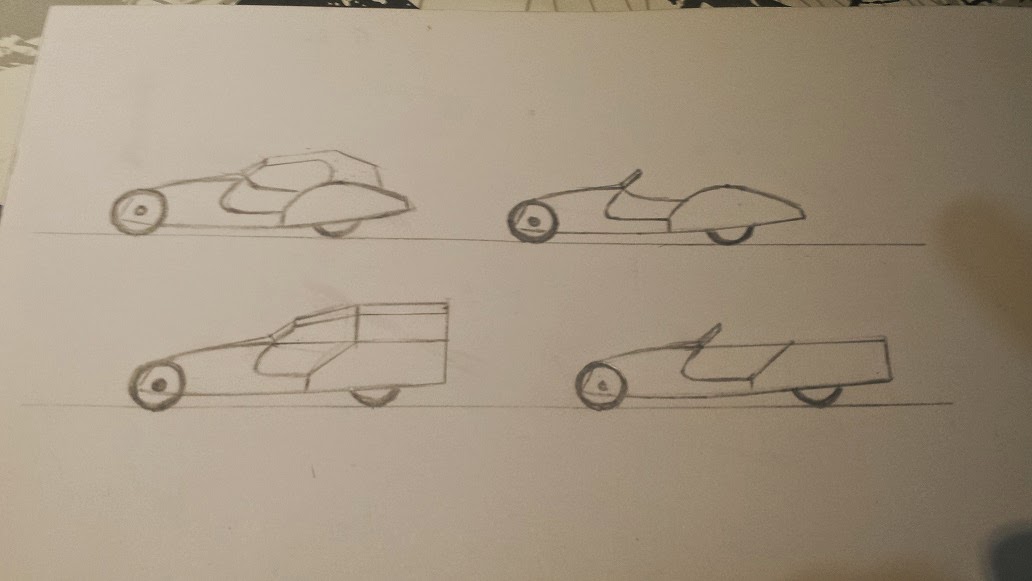

All the curves that are missed in the frame, I try to add to the bodywork.

As the old one it has to be a 2+2 seater to be used as a family cruiser.

While my old Retroadster has a steel frame, a rather heavy birch ply bodywork and weights 85kg, the new one has to be significantly lighter.

After excessive weight-vs-costs calculations of all possible materials I came to the conclusion to use gaboon plywood for the frame and body.

It's very light, much lighter than birch or even pine, it's relatively cheap, rot resistant and I can order it at my local wood store.

The weight target for the new velocar is around 65kg.

For the naked frame I calculated 15kg.

I began over the winter, cutted out all the plywood pieces.

For proper strength the plywood is reinforced with 20x20mm spruce stringers.

The whole construction is close to an old wooden airplane.

Now the frame nears completion.

I have to say, it's the most complicated and critical part of the velocar, because structurally most important.

If the frame breaks, all other parts are worthless.

But here it is:

The frame on the scale

The scale is showing 14.9kg, I estimate 16kg when 100% complete

Frame without top panel, note the square stringers

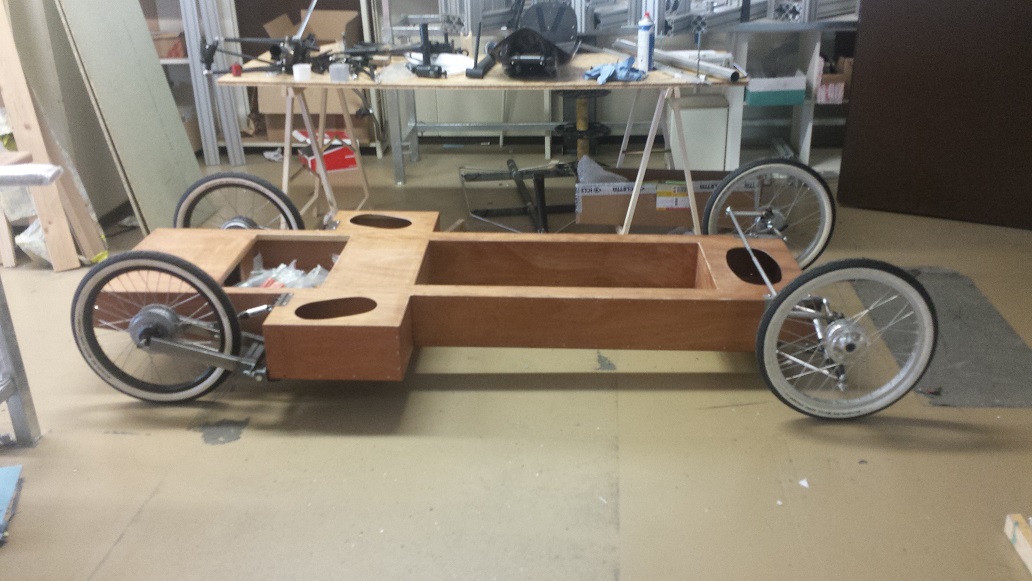

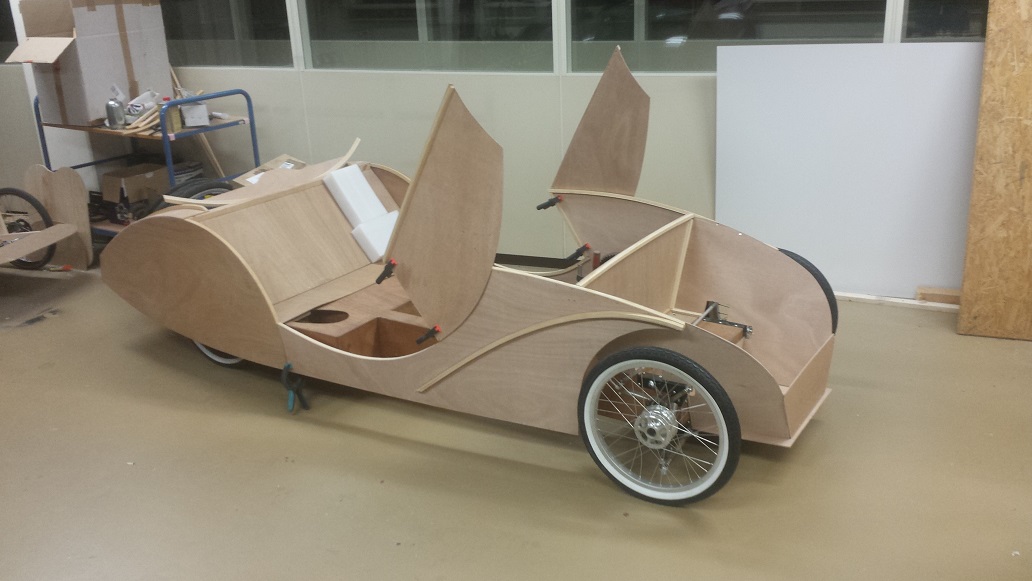

This mockup gives an idea, how the frame will be used

And the "special effects" are showing the future bodywork

The frame itself is too "cubistic" to win a cruiser bike design contest, but it's build for strength and durability.

The frame on the scale

The scale is showing 14.9kg, I estimate 16kg when 100% complete

Frame without top panel, note the square stringers

This mockup gives an idea, how the frame will be used

And the "special effects" are showing the future bodywork

All the curves that are missed in the frame, I try to add to the bodywork.